Numerically-controlled machine tool thermal error compensation method and system based on workpiece size data

A technology of numerical control machine tools and compensation methods, which is applied in the field of mechanical processing, can solve the problems of model accuracy decline, poor compensation effect, and failure to consider thermal deformation of workpieces, etc., and achieve the effect of thermal error compensation of machine tools

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

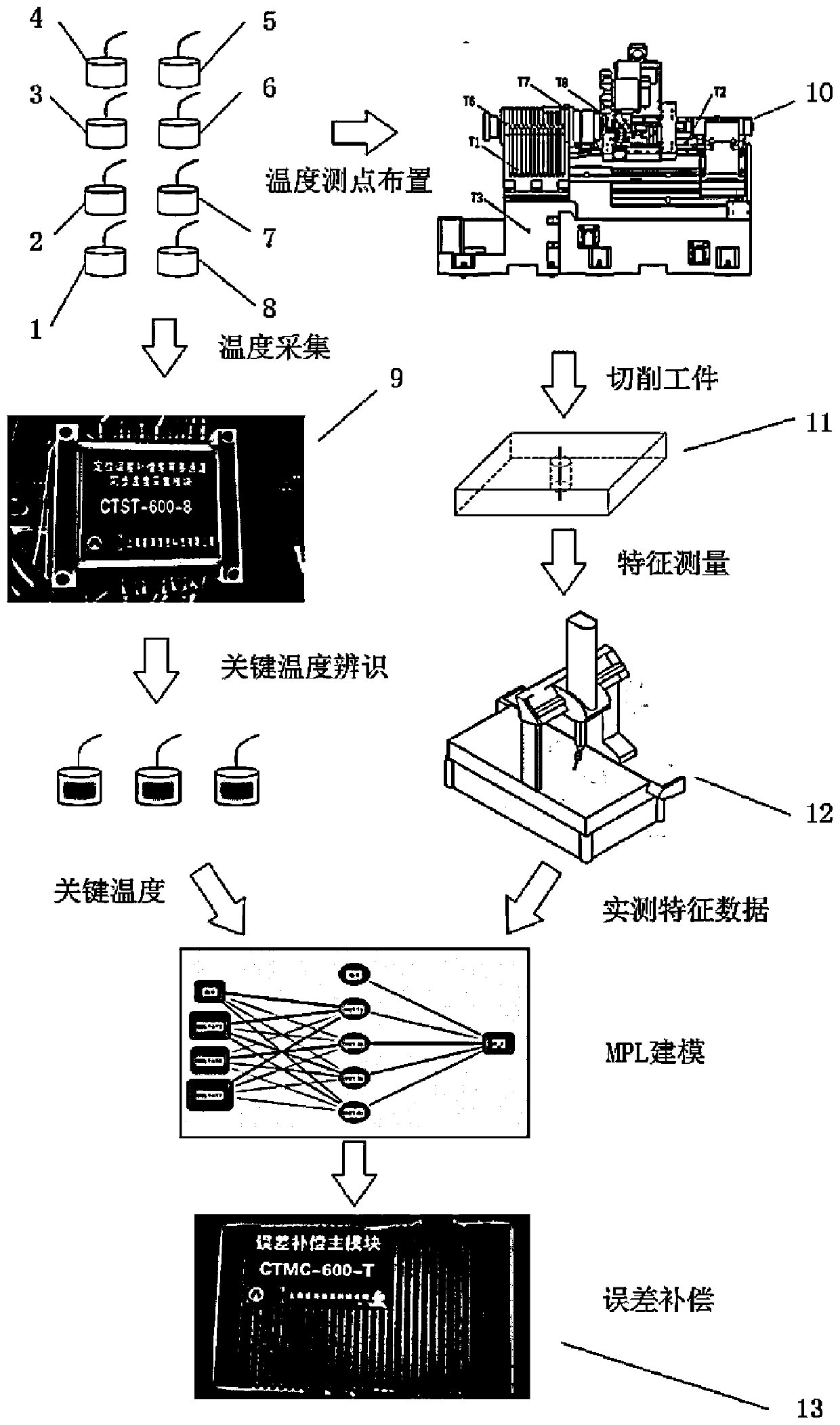

[0026] Such as figure 1 As shown, this embodiment relates to a measuring device for measuring the thermal error of a CNC machine tool and its specific application scenarios, including: a temperature sensor 1 for measuring room temperature, a temperature sensor 2 for lubricating oil temperature, and a temperature sensor for hydraulic oil temperature Temperature sensor 3, temperature sensor 4 for spindle front bearing temperature, temperature sensor 5 for coolant temperature, temperature sensor 6 for Z-axis screw temperature, temperature sensor 7 for spindle rear bearing temperature, and temperature sensor 8 for machine bed temperature, with The temperature acquisition module 9 with real-time temperature acquisition and data storage function, the CNC machine tool 10 for cutting tasks, the workpiece 11 for cutting, the three-coordinate measuring machine 12 for measuring the dimensional characteristics of the workpiece, and the interaction with the numerical control system and The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com