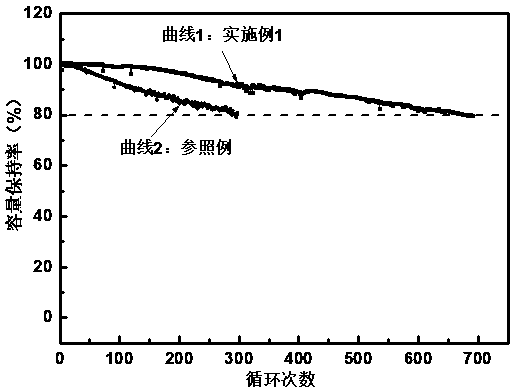

Formation method for prolonging cycle life of silicon-carbon soft package lithium ion battery

A lithium-ion battery, cycle life technology, applied to secondary batteries, electrochemical generators, secondary battery charging/discharging, etc., can solve the problems of fast cycle attenuation, large expansion coefficient, etc., and achieve expansion inhibition and strong stability , reducing the effect of the migration path

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A method for improving the cycle life of a silicon-carbon soft-packed lithium-ion battery, comprising the following steps:

[0027] Step 1: Use temperature control equipment to set the required temperature, and perform low-temperature static treatment on the battery cells for 12 hours;

[0028] Step 2: Pressurize the cell during the formation process;

[0029] Step 3: Carry out gradient small rate charging to the battery cell;

[0030] The overall ambient temperature is: 15°C;

[0031] The pressurization pressure of the cell is: 0.4 Mpa.

[0032] The specific steps of charging the battery cell at a gradient small rate are as follows:

[0033] The first stage: constant current charging, charging to 10% of the reversible capacity, charging current is 0.02C;

[0034] The second stage: constant current charging, charging to 30% of the reversible capacity, charging current is 0.08C;

[0035] The third stage: constant current charging, charging to 30% of the reversible c...

Embodiment 2

[0042] A method for improving the cycle life of a silicon-carbon soft-packed lithium-ion battery, comprising the following steps:

[0043] Step 1: Use temperature control equipment to set the required temperature, and perform low-temperature static treatment on the battery cells for 20 hours;

[0044] Step 2: Pressurize the cell during the formation process;

[0045] Step 3: Carry out gradient small rate charging to the battery cell;

[0046] The overall ambient temperature is: 0°C.

[0047] The pressurization pressure of the cell is: 0.6 Mpa.

[0048] The specific steps of charging the battery cell at a gradient small rate are as follows:

[0049] The first stage: constant current charging, charging to 15% of the reversible capacity, charging current is 0.03C;

[0050] The second stage: constant current charging, charging to 20% of the reversible capacity, charging current is 0.05C;

[0051] The third stage: constant current charging, charging to 40% of the reversible ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com