Motor control system

A technology of motor control and button control, applied in control systems, motor generator control, AC motor direction control, etc., can solve problems such as single product function and lack of perfect control system system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Example 1: Please refer to Figure 1-13 In the embodiment of the present invention, resistors R1 to R14, varistors RV, capacitors C1 to C6, rectifier diodes D1 to D4, Zener diode ZD, bidirectional trigger diode DIAC, transistors Q1, Q2, high voltage package T1, optocoupler U1, relay JD and ignition needle / flame needle IG. In this circuit, relay JD, resistor R2, diodes D1, D2, capacitor C5, bidirectional trigger diode DIAC, varistor RV, high-voltage package T1 constitute the pulse ignition circuit, and the other parts constitute the flame detection circuit.

[0030] Such as figure 1 As shown, in this circuit, resistor R1 is connected to one end of resistor R2 and the N pole of the 220V AC power supply neutral line,

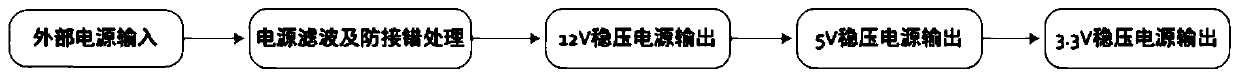

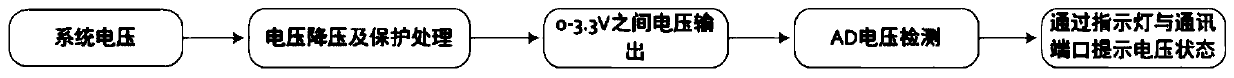

[0031] The voltage detection circuit converts the input voltage of the external power supply into the voltage that needs to be applied to the system module. The current system mainly consists of three types of voltage

[0032] 1: External voltage (12-24V). Syst...

Embodiment 2

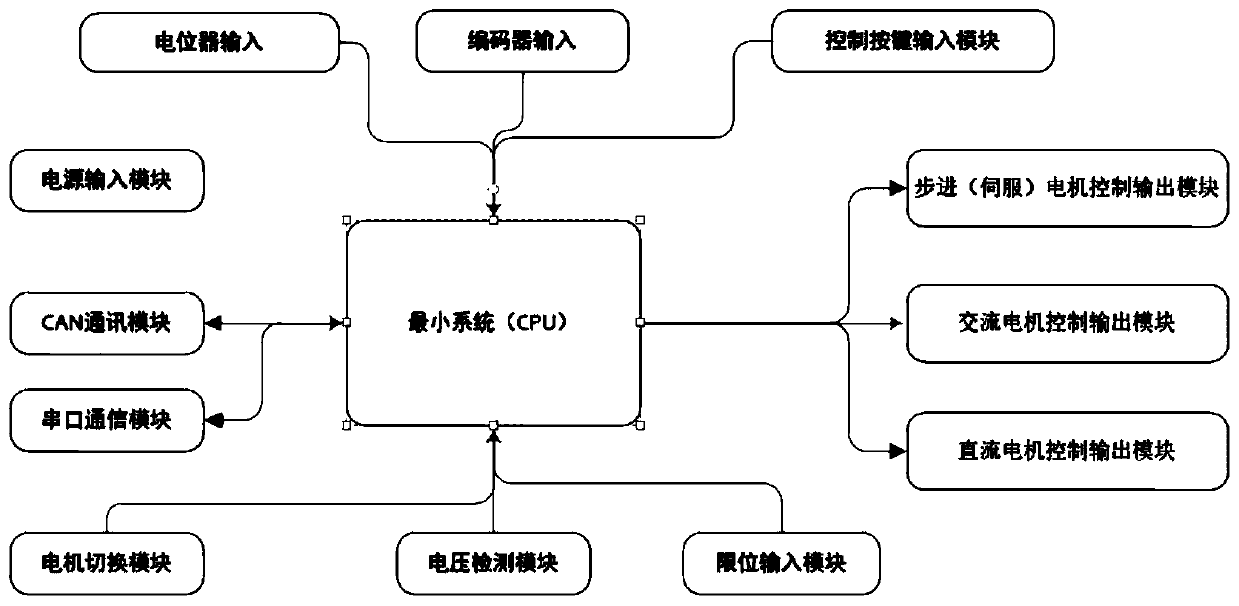

[0047] Embodiment 2: On the basis of Embodiment 1, the minimum CPU system adopts a single-chip microcomputer with the highest frequency of 72MHz, which can quickly process the collected data and communicate with the server. The internal integrated 12-bit AD converter can ensure the accuracy of voltage acquisition. The internal timer is responsible for collecting the pulse value of the encoder. The collected data realizes the requirements of different distances or angles through internal algorithms. Realize the forward and reverse rotation of the motor through key input or communication protocol input. The movement of the motor drives the potentiometer or encoder for movement acquisition.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com