Customized ulna prosthesis

A prosthesis, ulna technology, applied in the direction of prosthesis, manufacturing tools, additive manufacturing, etc., can solve the problems of unable to replace the ulna, unable to retain the distal end of the humerus, poor stability, etc., achieve light specific gravity, improve ingrowth, stability good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

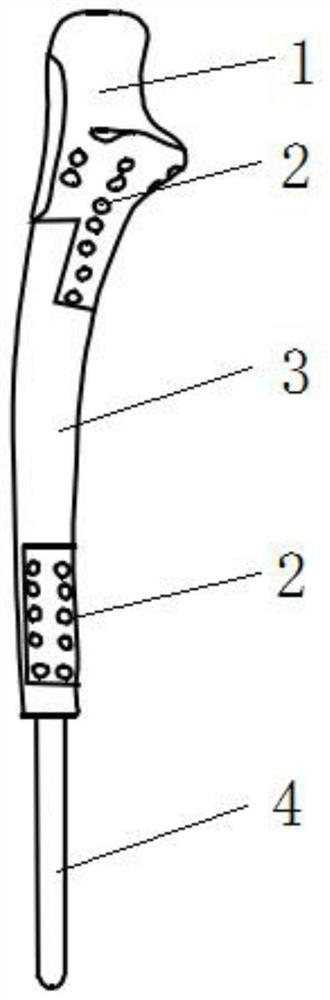

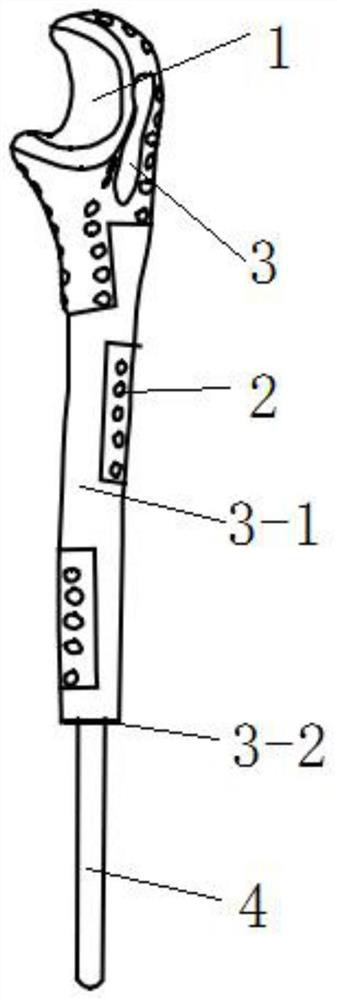

[0028] Please refer to the attached Figure 1-2 , The purpose of this embodiment is to provide a customized ulnar prosthesis, including: a prosthesis body, the material of which is titanium alloy, which has the characteristics of high strength and light specific gravity. The upper end of the prosthesis body is provided with an olecranon groove 1, and the olecranon groove 1 is polished to make the joint surface of the ulnar prosthesis smooth, reduce the wear of the ulnar prosthesis and the human elbow joint surface, and prolong the service life of the prosthesis. The lower end of the prosthesis body is provided with a medullary needle 4, and the medullary needle 4 is a bionic type of medullary needle; the surface of the medullary needle 4 is sprayed, and the surface of the medullary needle 4 has a titanium coating and a hydroxyapatite coating. and tantalum coating; the surface of the sprayed needle 4 is a rough surface with holes, and the holes are preferably micropores. Biomi...

Embodiment 2

[0033] Please refer to the attached Figure 1-2 , The purpose of this embodiment is to provide a customized ulna prosthesis, including: a prosthesis body, the material of the prosthesis body is titanium alloy, which has the characteristics of high strength and light specific gravity. The upper end of the prosthesis body is provided with an olecranon groove 1, and the olecranon groove 1 is polished to make the joint surface of the ulnar prosthesis smooth, reduce the wear of the ulnar prosthesis and the human elbow joint surface, and prolong the service life of the prosthesis. The lower end of the prosthesis body is provided with a medullary needle 4, and the medullary needle 4 is a bionic type of medullary needle; the surface of the medullary needle 4 is sprayed, and the surface of the medullary needle 4 has a titanium coating and a hydroxyapatite coating. and tantalum coating; the surface of the sprayed needle 4 is a rough surface with holes, and the holes are preferably micro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com