Feeding box for thickener and using method thereof

A technology of thickener and feeding box, applied in separation methods, chemical instruments and methods, feeding/discharging devices of sedimentation tanks, etc. To improve the efficiency of flocculation and settling, improve the effect of flocculation and settling, and achieve the effect of good flocculation and settling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

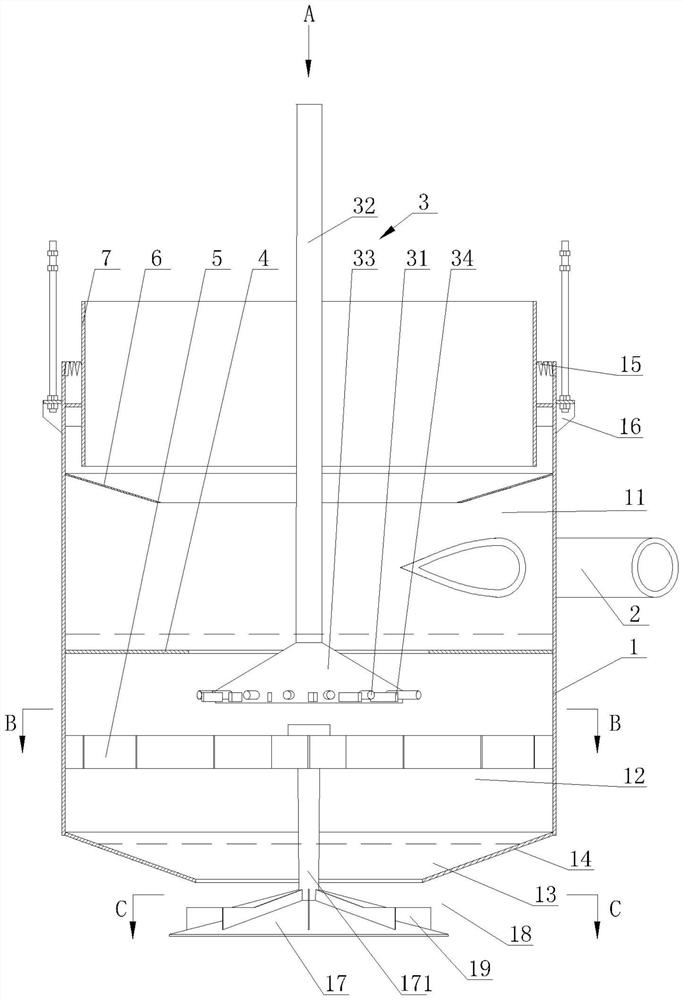

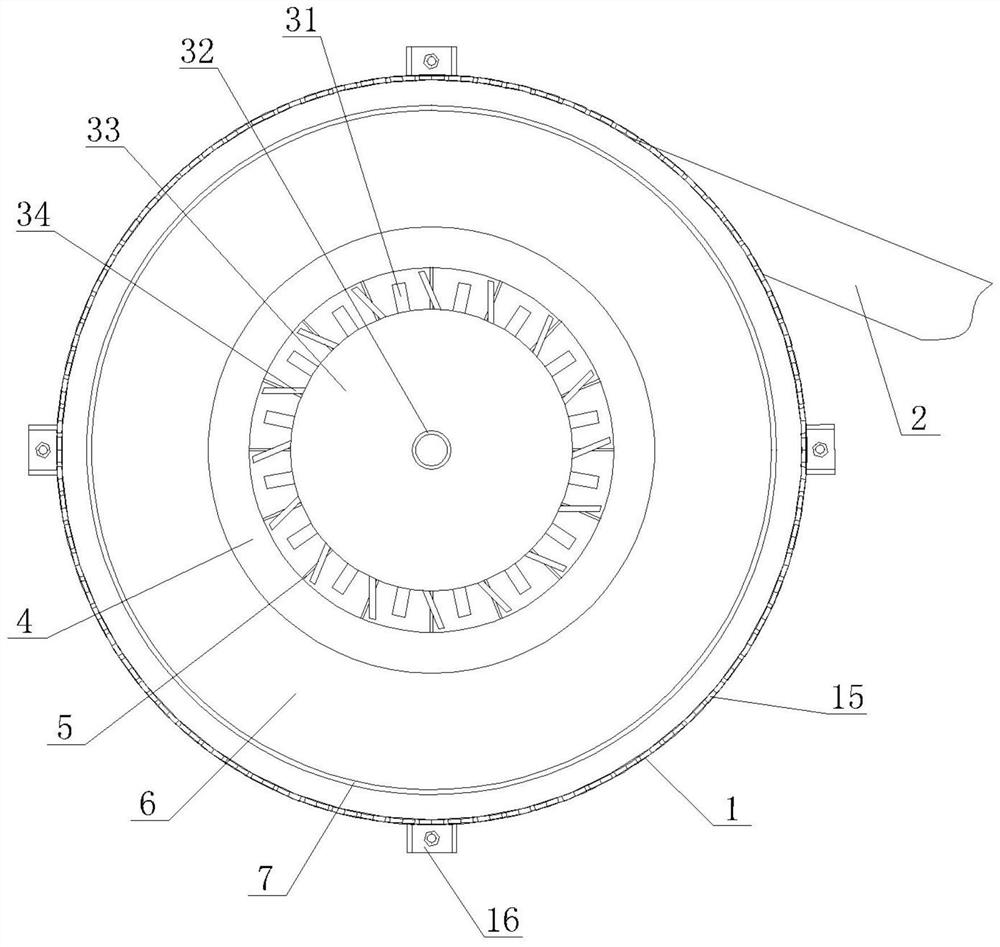

[0043] From Figure 1 to Figure 4 It can be seen that the feed box for the thickener of the present invention includes a feed barrel 1, a feed pipe 2, a flocculant addition pipe 3, an annular deflector 4 and an energy dissipation vertical plate 5,

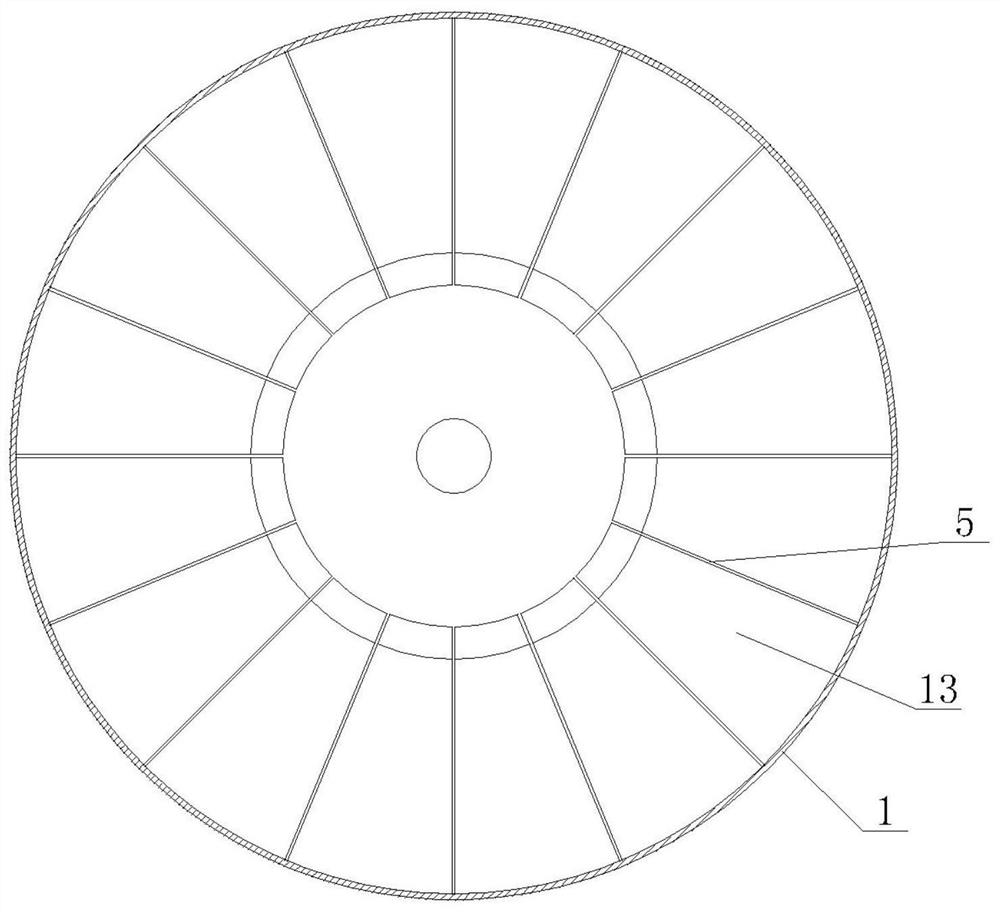

[0044] The inside of the feed barrel 1 is divided into a feed dilution zone 11, a flocculation mixing zone 12 and a floc unloading zone 13 arranged sequentially from top to bottom. The opening at the bottom of the material section 14 is arranged in the floc unloading area 13; there is a sawtooth weir 15 on the top of the feeding barrel 1, and the feeding barrel 1 is hoisted in the body of the thickener through the hanging ears 16 arranged on its outer wall, and the sawtooth weir 15 is located in the clarification area of the thickener body;

[0045] The feed pipe 2 is connected to the feed tank 1 at the lower part of the feed dilution zone 11 along the tangential direction;

[0046] The annular deflector 4 is fixed in the feedi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com