A kind of rapid flocculation water treatment agent and its preparation method and water treatment method

A water treatment agent and flocculation technology, applied in the field of water treatment, can solve the problems of unsatisfactory flocculation speed in the treatment of raw water, achieve wide and excellent adsorption properties, strong decolorization ability, and improve the effect of flocculation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

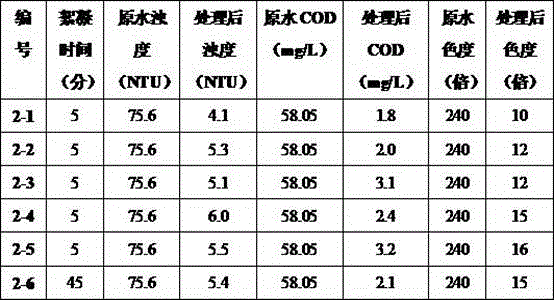

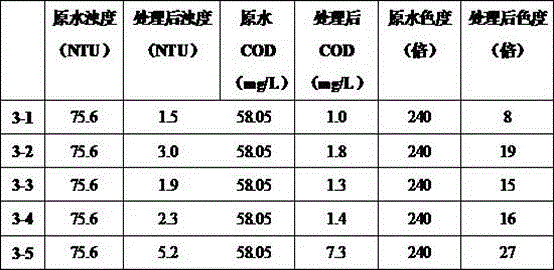

Examples

Embodiment 1-1

[0047] (1) Carboxylation of graphene oxide

[0048] Add sodium hydroxide and chloroacetic acid to 5 mg / mL graphene oxide aqueous solution, graphene oxide aqueous solution: sodium hydroxide: chloroacetic acid = 1L: 2g: 2g, mix and react for 1 hour, separate and wash to obtain carboxylated oxidation Graphene;

[0049] (2) Preparation of carboxylated ferric oxide

[0050] Ferric trichloride, sodium acrylate, anhydrous sodium acetate and ethylene glycol mixture are transferred to the reaction kettle, wherein when ferric chloride, sodium acrylate, anhydrous sodium acetate and ethylene glycol are mixed, the feed ratio is 27g: 75g: 75g: 1000ml, react at 200°C, after cooling, wash with ethanol and deionized water to obtain surface carboxylated ferric oxide;

[0051] (3) Preparation of acrylamide oligomer / graphene oxide / ferric oxide composite

[0052]Mix carboxylated graphene oxide, surface carboxylated ferric oxide and acrylamide oligomer in DMSO, add EDCI, among them, DMSO: carbox...

Embodiment 1-2

[0062] In this example, the preparation process of the rapid flocculation water treatment agent is the same as Example 1-1, only the ratio of each component is adjusted.

[0063] The parts by weight of each component are as follows:

[0064] Acrylamide oligomer / graphene oxide / Fe3O4 complex 8,

[0065] Polyacrylamide 35,

[0066] Ferric aluminum polysilicate 35,

[0067] Polydimethyldiallylammonium Chloride 20,

[0068] sodium bicarbonate 5.

Embodiment 1-3

[0070] In this example, the preparation process of the rapid flocculation water treatment agent is the same as Example 1-1, only the ratio of each component is adjusted.

[0071] The parts by weight of each component are as follows:

[0072] Acrylamide oligomer / graphene oxide / ferric oxide complex 6,

[0073] Polyacrylamide 40,

[0074] Ferric aluminum polysilicate 30,

[0075] Polydimethyldiallylammonium Chloride 25,

[0076] sodium bicarbonate 5.

PUM

| Property | Measurement | Unit |

|---|---|---|

| ionicity | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

| decolorization rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com