Sewage floating object treatment device based on flocculent precipitation

A technology for treating devices and floating objects, which is applied in the fields of flocculation/sedimentation water/sewage treatment, water/sewage treatment, water/sludge/sewage treatment, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

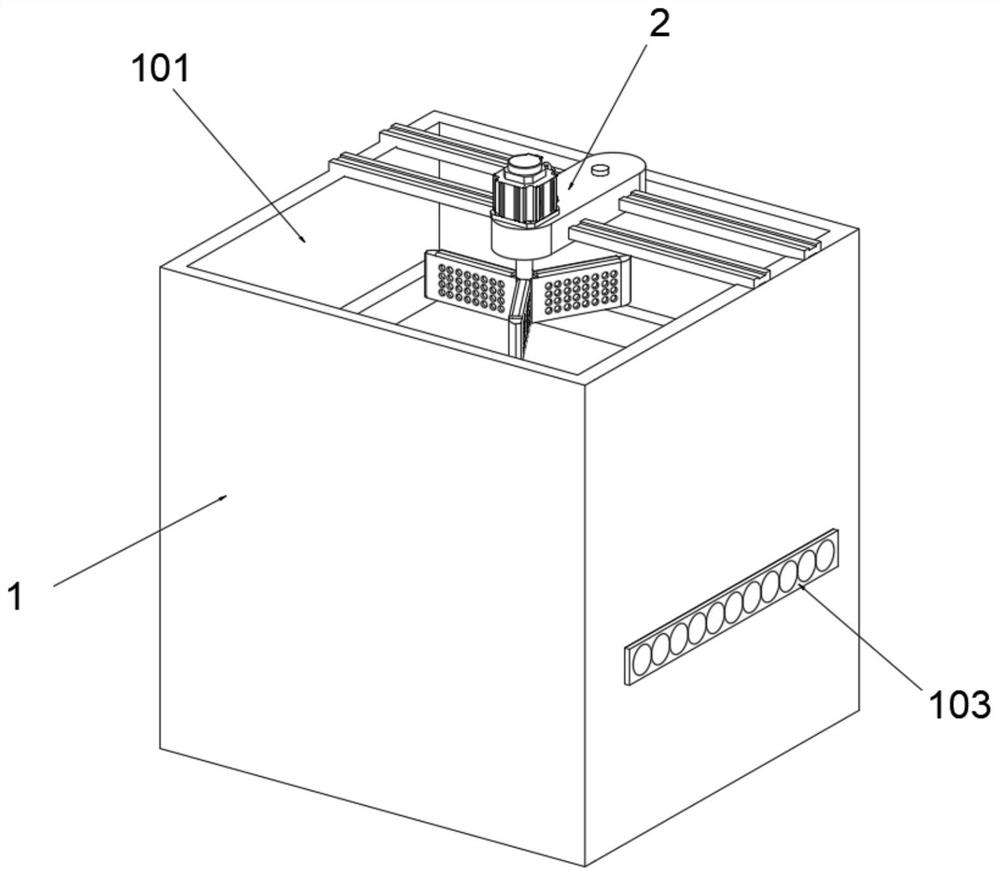

[0047] see Figure 1-Figure 7 As shown, the purpose of the present invention is to provide a sewage floating treatment device based on flocculation and sedimentation, including a housing 1 and a stirring part 2 and a settling area 3 installed in the housing 1:

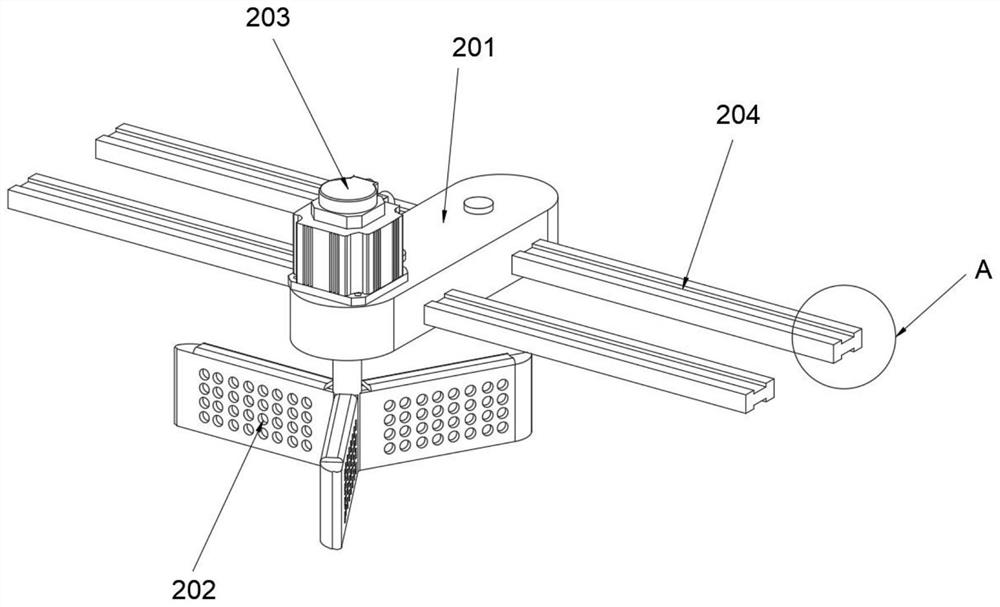

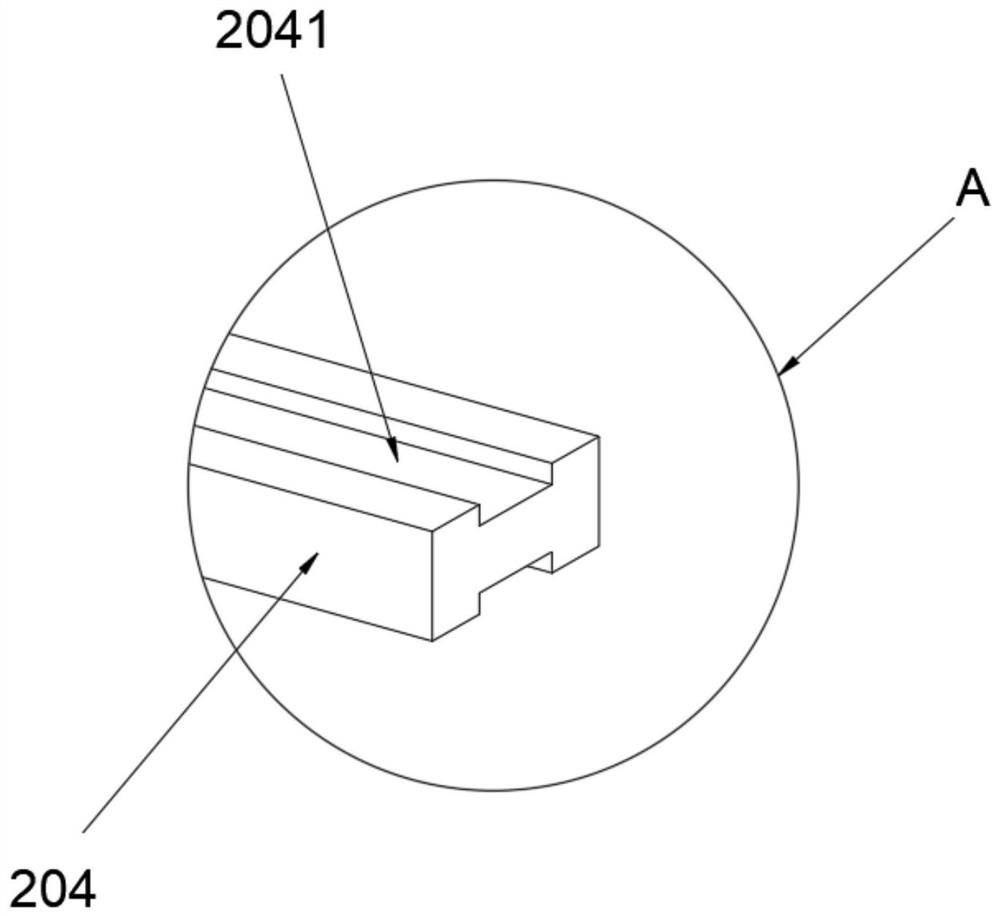

[0048] The stirring part 2 includes at least a support base 201, the upper surface of the support base 201 is provided with a shaft hole 2011 near one end edge, the upper surface of the support base 201 is fixedly equipped with a stirring motor 203, and the output shaft of the stirring motor 203 is coaxially connected to the shaft hole 2011. Stirring member 202, the stirring member 202 at least includes stirring blade 2021, the stirring blade 2021 extends into the sewage until the sewage completely submerges the stirring blade 2021, the top of the stirring blade 2021 is fixedly connected with the stirring shaft 2023, the output shaft of the stirring motor 203 and the stirring shaft 2023 is coaxially connected, the top ...

Embodiment 2

[0053] see Figure 8-Figure 16 As shown, the object of the present invention is to provide a sewage floating matter treatment device based on flocculation and sedimentation, including a housing 1, the top of the housing 1 is fixedly equipped with support arms 204 on both sides of the mouth, and the side wall of the inner cavity of the housing 1 A filter screen 1011 is fixedly installed near the top, a flocculation reaction zone 101 is set between the shell 1 and the filter screen 1011, and an inclined partition 102 is fixedly installed on the side wall of the inner cavity of the shell 1 close to the bottom of the filter screen 1011. A clean water outlet 103 is provided on the side wall of the body 1 close to the bottom of the inclined partition 102, and a filter screen is arranged outside the clean water outlet 103 to prevent sediment from being discharged with the water flow.

[0054] Wherein, the drug storage part 2022 includes at least a top seat 20221, and the upper surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com