Pressurized kitchen waste crushing and degrading device and process

A kitchen waste and process technology, applied in the field of pressurized kitchen waste crushing and degrading joint treatment, can solve the problems of low degradation efficiency and high processing cost of the kitchen waste, solve the problem of insufficient drainage capacity, increase the reaction area, and reduce the volume Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in further detail below in conjunction with the accompanying drawings.

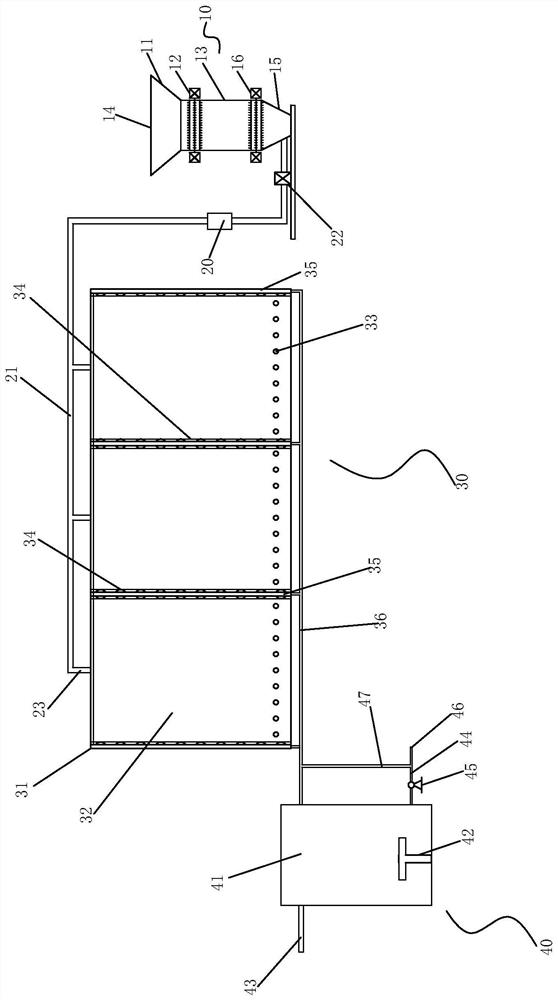

[0039] refer to figure 1 , is a pressurized food waste crushing and degradation device disclosed in the present invention; it mainly includes a feed crushing assembly 10, a feed activation assembly 20, and a pressurized reaction assembly that are connected in sequence and made of carbon steel anticorrosion or 316L stainless steel. 30 and effluent reuse assembly 40; the feed crushing assembly 10 is connected to one end of the pressurized reaction assembly 30 through the bottom activation pipeline 21, and the activation pipeline 21 is provided with the feed activation assembly 20 and pump pressure equipment, and the pressurized reaction assembly 30 is additionally One end is connected with the effluent reuse assembly 40 .

[0040]The feeding and crushing assembly 10 of the present invention includes a feeding hopper 11 and a blanking cylinder 13; both the feed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com