Forging forming method of cutting pick with reinforcing rib

A forging forming and reinforcing rib technology, applied in the direction of manufacturing tools, hammer driving devices, metal processing equipment, etc., can solve the problems such as the force at the bottom end of the forging head cannot be guaranteed to be exactly in the center, the forging head is inclined, and the guide sleeve is damaged. , to achieve the effect of enhancing the overall use effect, enhancing the driving force and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

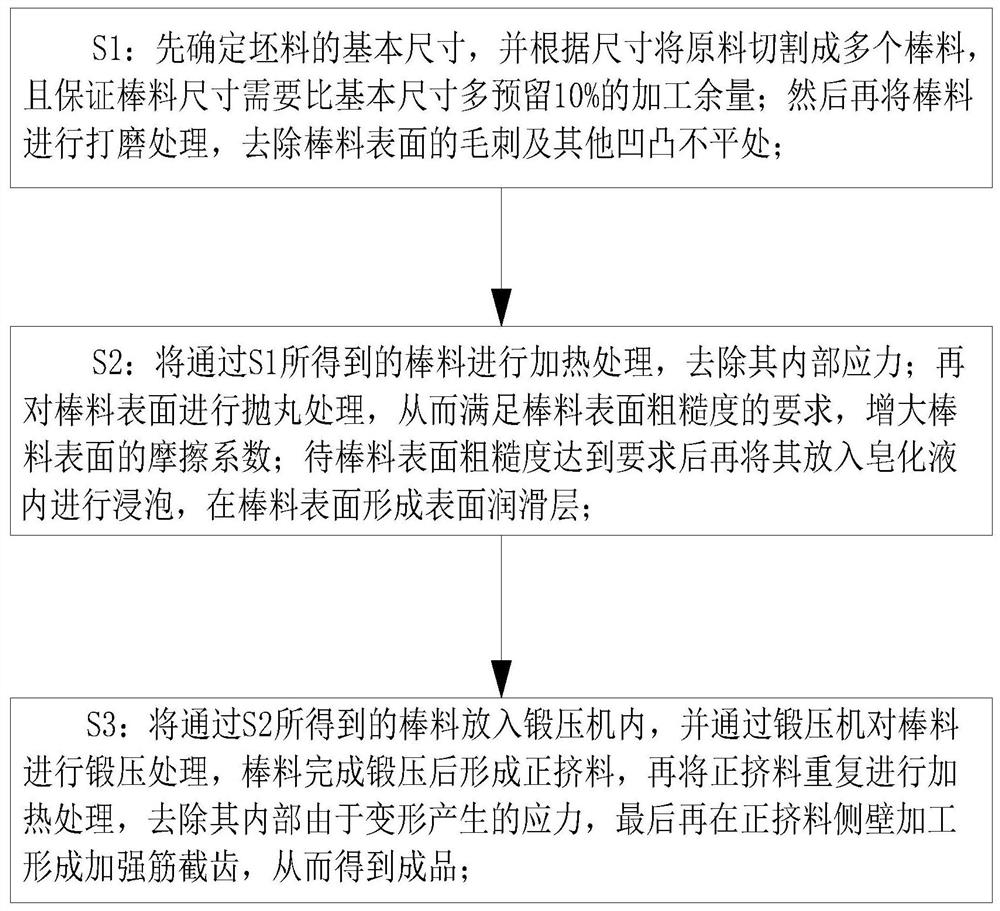

Method used

Image

Examples

Embodiment approach

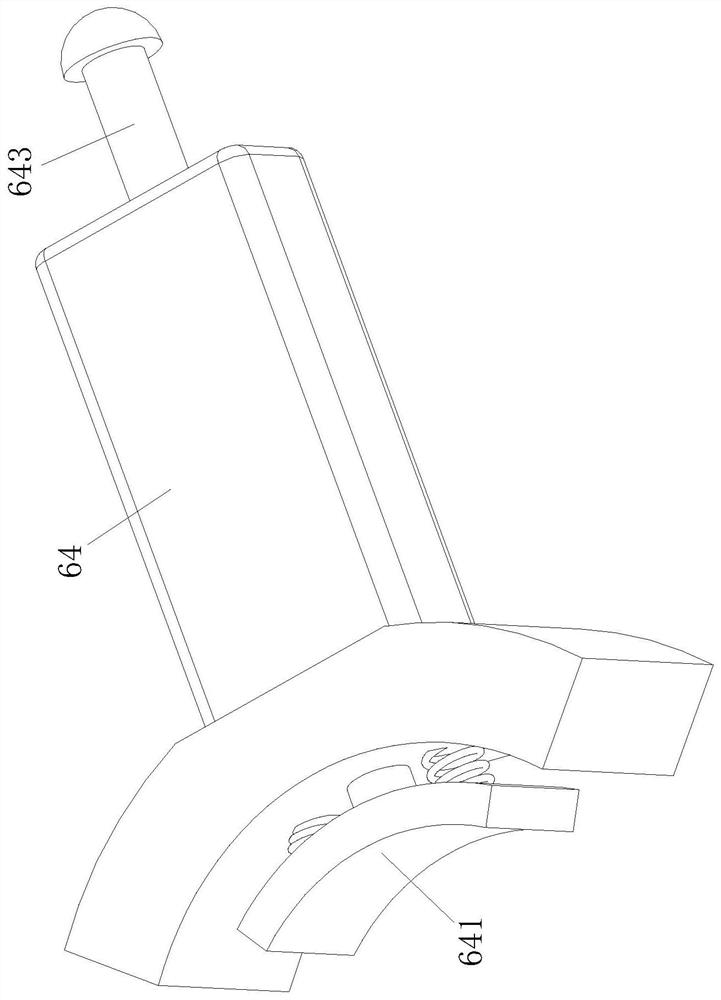

[0034] As a specific embodiment of the present invention, the second cavity 631 is provided with a wave-shaped groove 632 on the side wall close to the push rod 643; The concentrated effect of the thrust of the rod 643; when working, during the extrusion process of the clamp block 64 on the rubber pad 63, the rubber pad 63 can provide extrusion force to the push rod 643, pushing the push rod 643 to slide in the direction close to the guide post 62 , the ejector rod 643 can squeeze the friction block 641 during the sliding process, thereby strengthening the overall straightening effect of the block 64 on the guide post 62. After forming the groove 632, the deformation direction of the second cavity 631 is changed, and the gathering effect on the deformation force of the second cavity 631 is realized, thereby ensuring the effective use of the deformation force of the second cavity 631 and strengthening the overall forging press use effect.

[0035] As a specific embodiment of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com