Disc milling cutter for efficiently milling large plane with large cutting depths

A large plane and disk milling cutter technology, applied in the field of milling, can solve the problems of milling not suitable for different depths, etc., and achieve the effect of simple structure, stable stability and convenient manufacture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

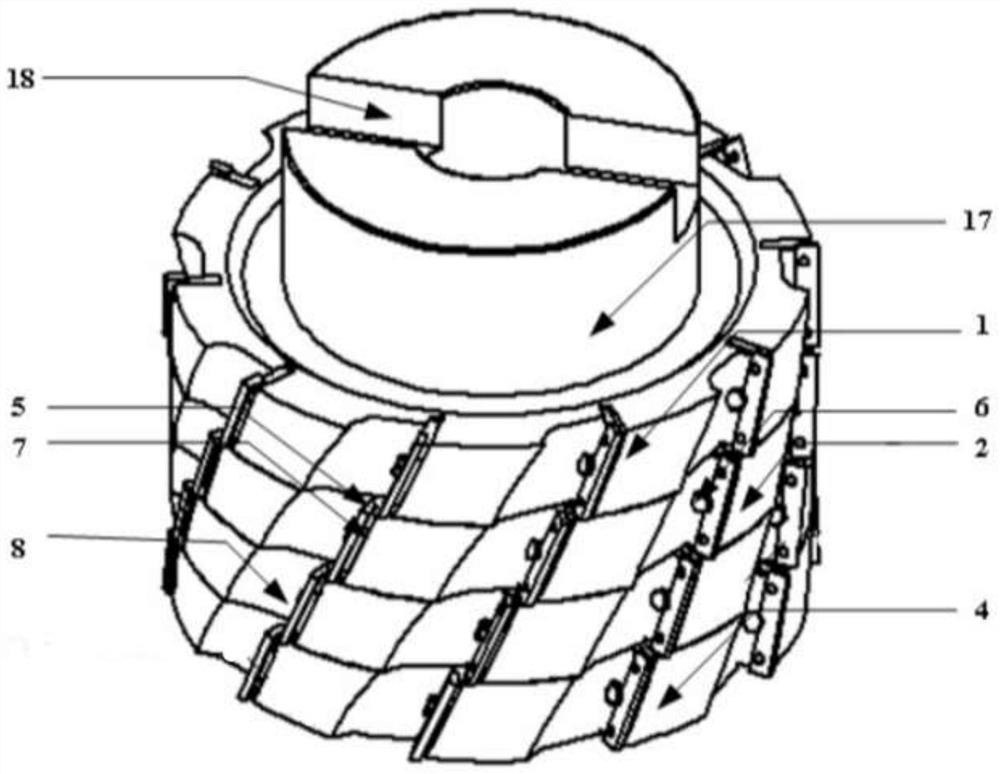

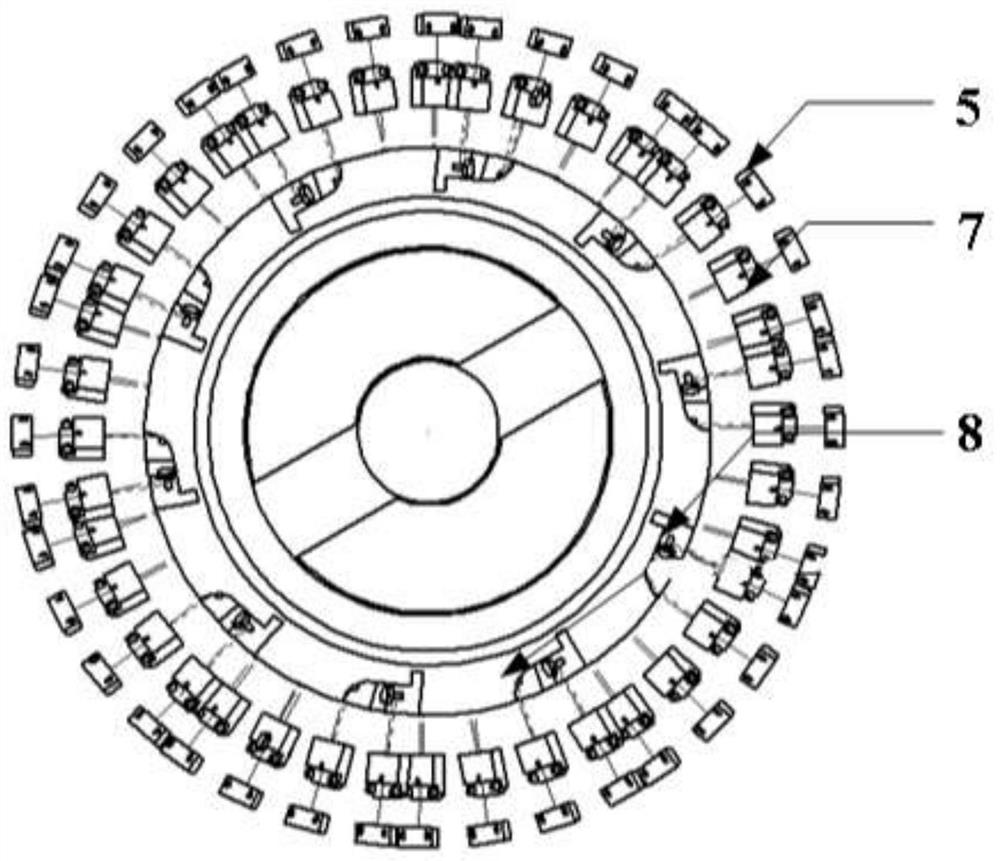

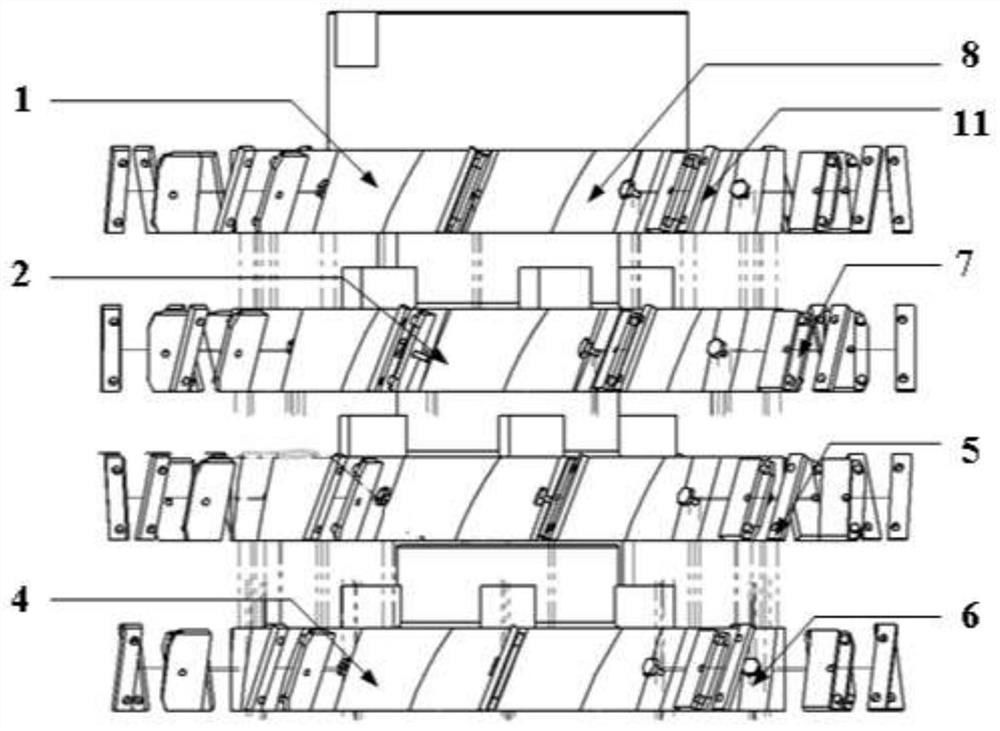

[0027] A disc milling cutter for high-efficiency milling of large planes and large depths of cut, see figure 1 , image 3 , Figure 4 , Figure 5 with Image 6 , including the upper milling cutter disc 1, the bottom of the upper milling cutter disc 1 is equipped with several middle milling cutter discs 2, the number of the middle milling cutter discs 2 can be selected according to the actual milling depth, the lowermost middle milling cutter disc 2 Bottom milling cutter disc 4 is installed on the bottom of the bottom milling cutter disc 4, the upper milling cutter disc 1, the middle milling cutter disc 2 and the bottom milling cutter disc 4 have the same diameter and thickness, the diameter is 200mm, and the thickness is 50mm. The upper milling cutter disc 1 and the middle ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap