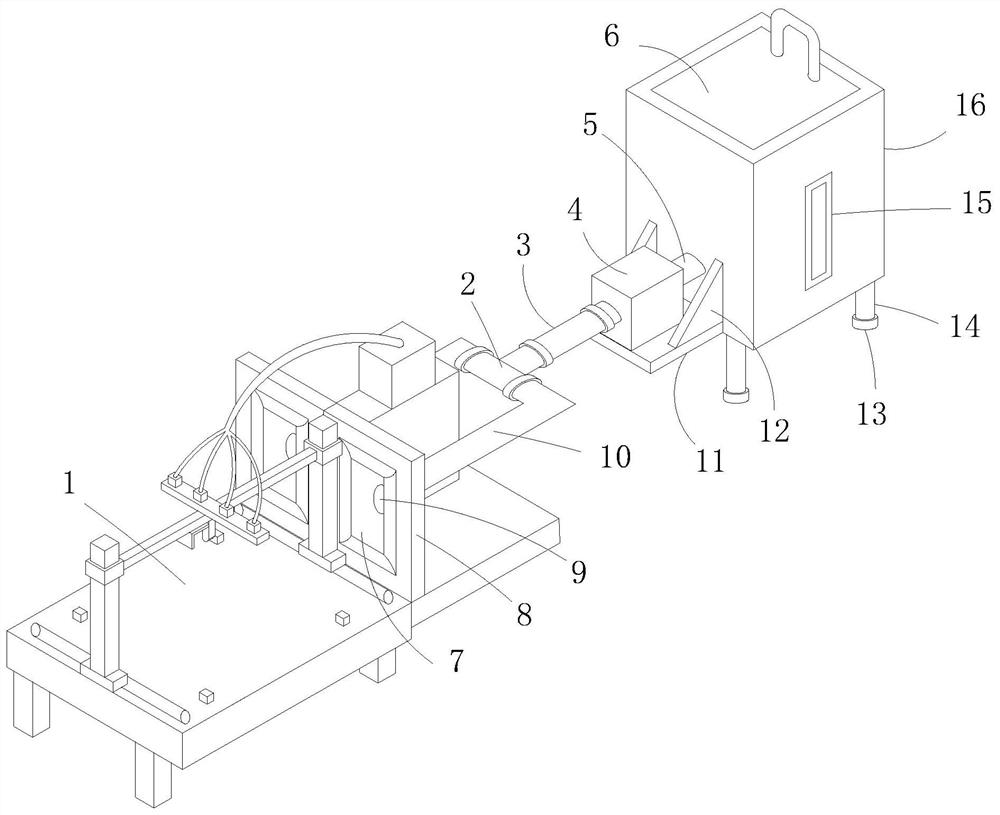

Full-color 3D printer

A 3D printer and motor technology, applied in the direction of 3D object support structure, smoke removal, additive manufacturing, etc., can solve the problems of unfavorable operator's health, affecting the processing environment, waste of printing materials, etc., to save printing materials and increase the contact area. , Improve the effect of purification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

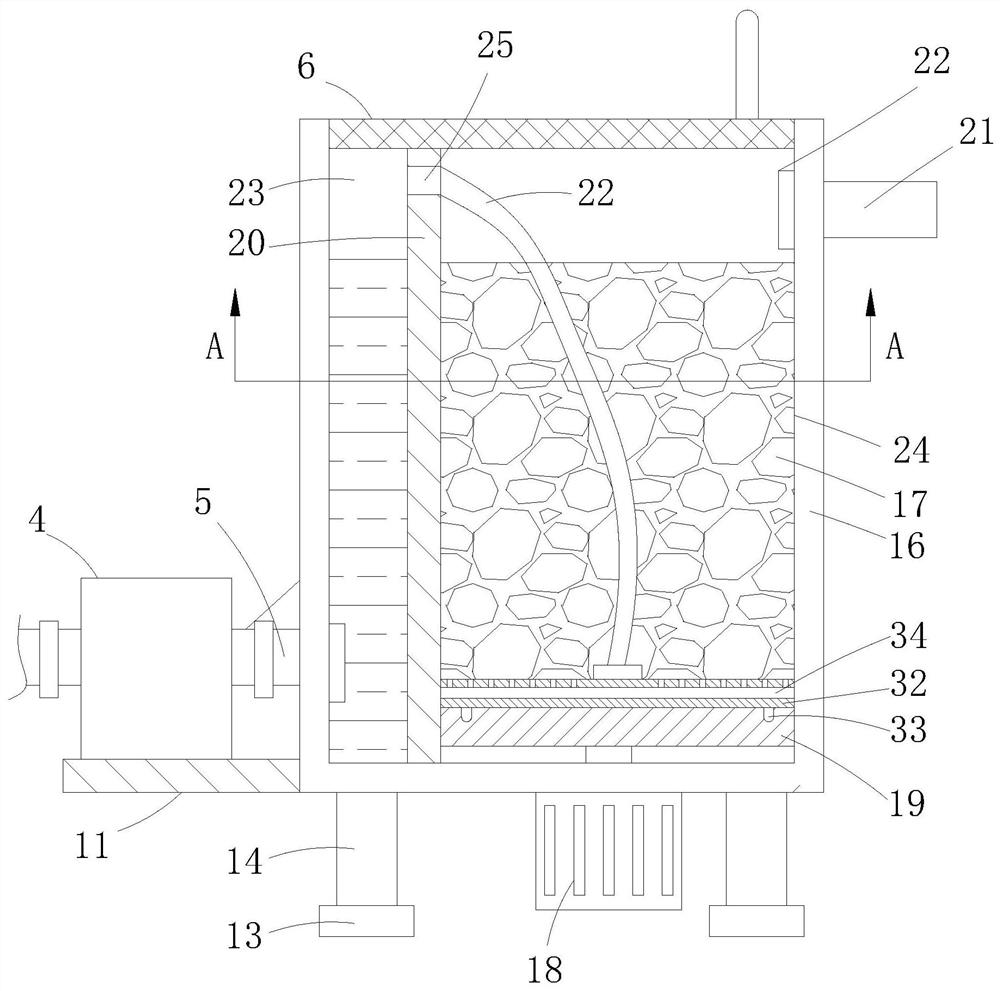

[0023] As an embodiment of the present invention, a sealing block 26 is fixedly connected to the second air extraction pipe 10, and the sealing block 26 is arranged close to the inner wall of the second air extraction pipe 10; a collecting tank 27 is provided in the second air extraction pipe 10; Collecting tank 27 communicates with the inner space of the air extraction pipe 10 on the left and right sides of the sealing block 26; the collection tank 27 is designed in an arc shape; the outer surface of the air extraction pipe 2 10 is provided with a discharge port 28; the discharge port 28 communicates with the collection tank 27 Bottom; the outlet 28 is provided with a rubber plug; the exhaust pipe 2 10 is provided with a heating block 29 below the collection tank 27; the heating block 29 is electrically connected to an external power supply; the heating block 29 is used for the collection tank 27 for heating; the exhaust pipe 2 10 is provided with evenly arranged shunt grooves...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com