Pantograph with stable contact pressure

A contact pressure and pantograph technology, applied in the field of pantograph, can solve the problems of train outage, system power failure, poor current receiving of locomotives, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

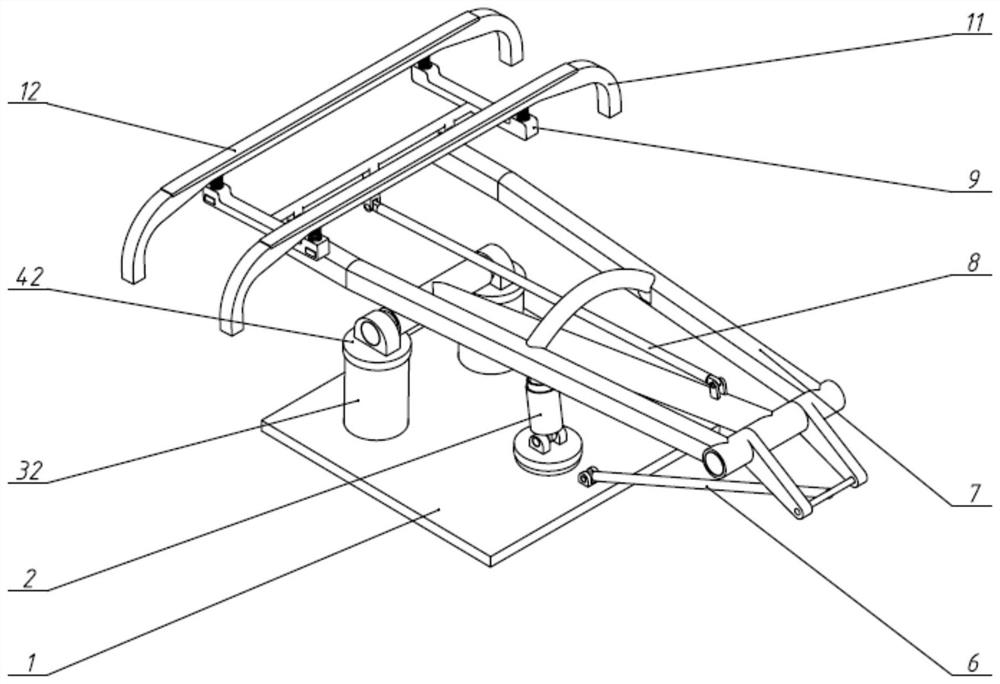

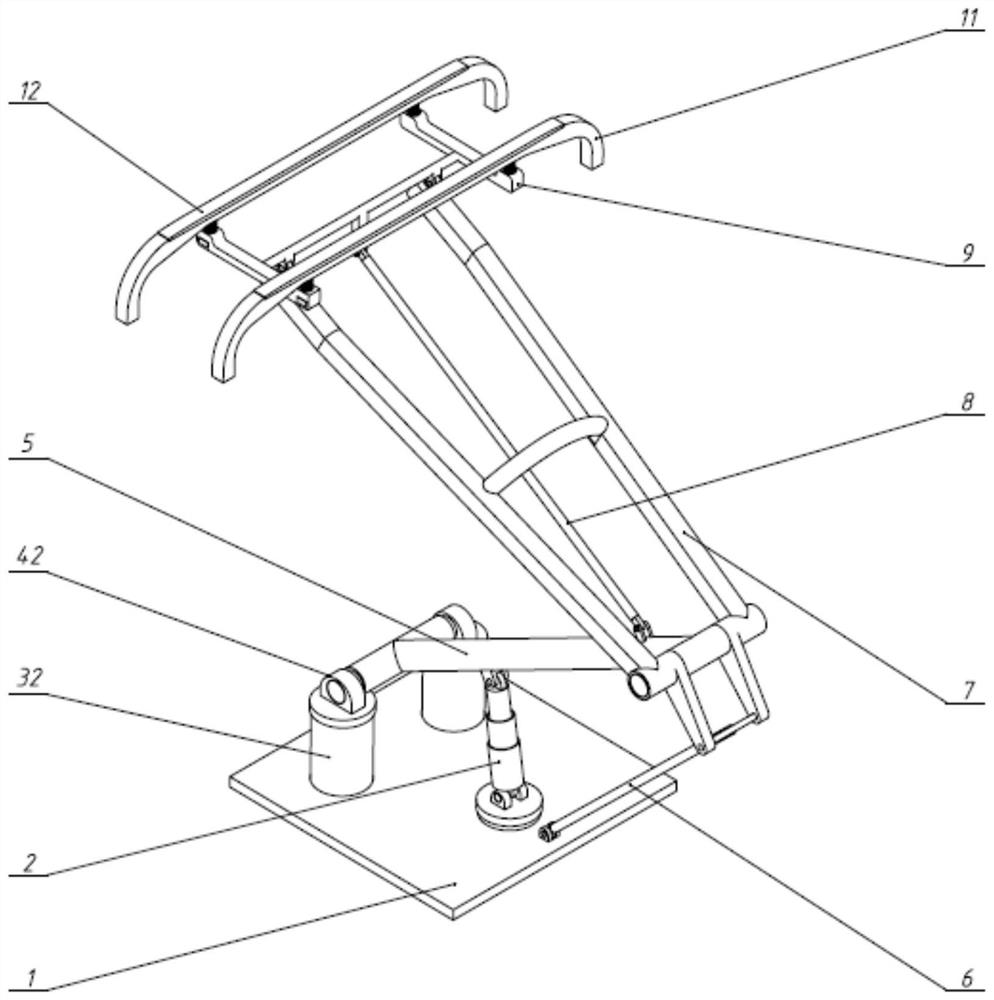

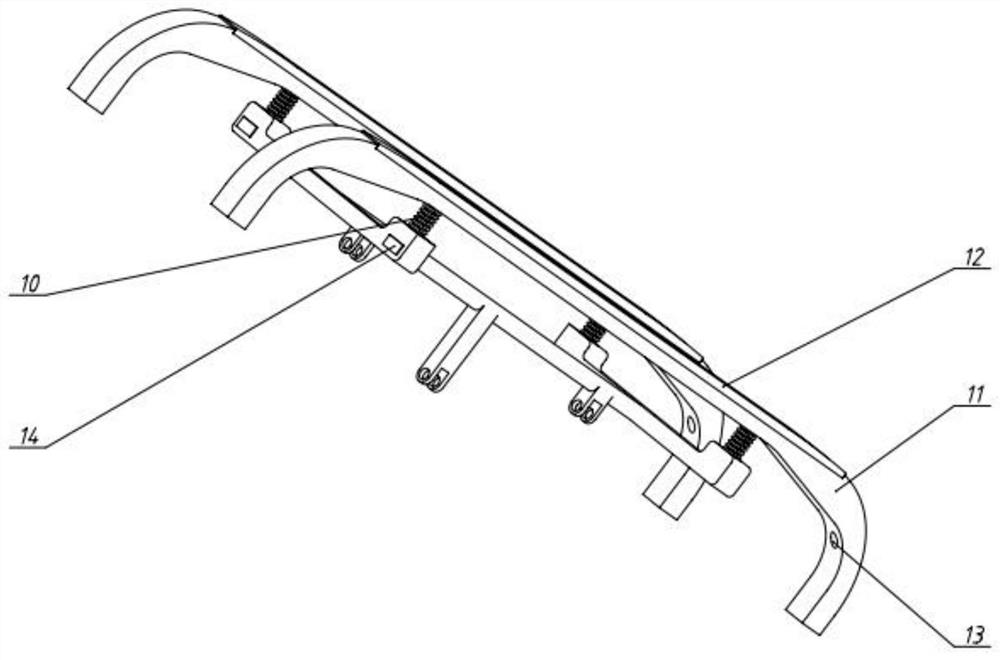

[0021] The present invention will be further described below in conjunction with accompanying drawing:

[0022] Such as Figure 1 to Figure 5 As shown, a pantograph with stable contact pressure includes base plate 1, hydraulic thruster 2, rubber spring I31, mounting seat I41, lower arm 5, rubber spring II32, mounting seat II42, lower guide rod 6, mounting seat Ⅲ43, upper arm 7, upper guide rod 8, mounting seat Ⅳ44, bow head frame 9, steel spring 10, bow head 11, carbon slide plate 12, light source mounting hole 13 and photosensitive plate 14, the mounting seat I41 and mounting seat II42 respectively It is connected with the bottom plate 1 by rubber spring I31 and rubber spring II32, bottom plate 1, rubber spring I31, rubber spring II32, mounting base I41, mounting base II42 and mounting base III43 form the bottom device; the hydraulic propeller 2 is hinged with mounting base I41 , the lower arm 5 is hinged with the mounting base II42, the lower guide rod 6 is hinged with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com