Automatic stacker for making aluminum-foil paper packing food boxes

A technology of aluminum foil paper and palletizer, which is applied in the field of automatic palletizer for the production of aluminum foil paper packaging lunch boxes, which can solve the problems of not being able to keep up with the production efficiency of the machine, deformation of aluminum foil paper packaging lunch boxes, and slow collection and sorting efficiency of workers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

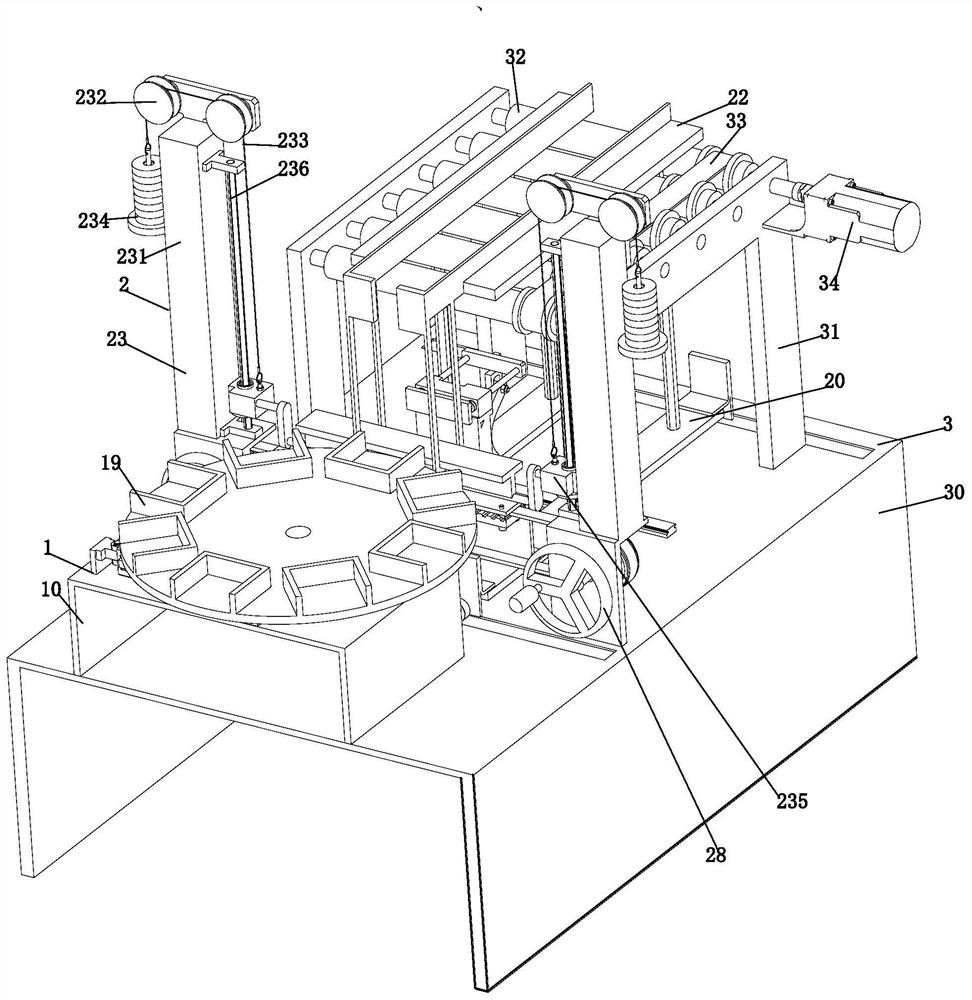

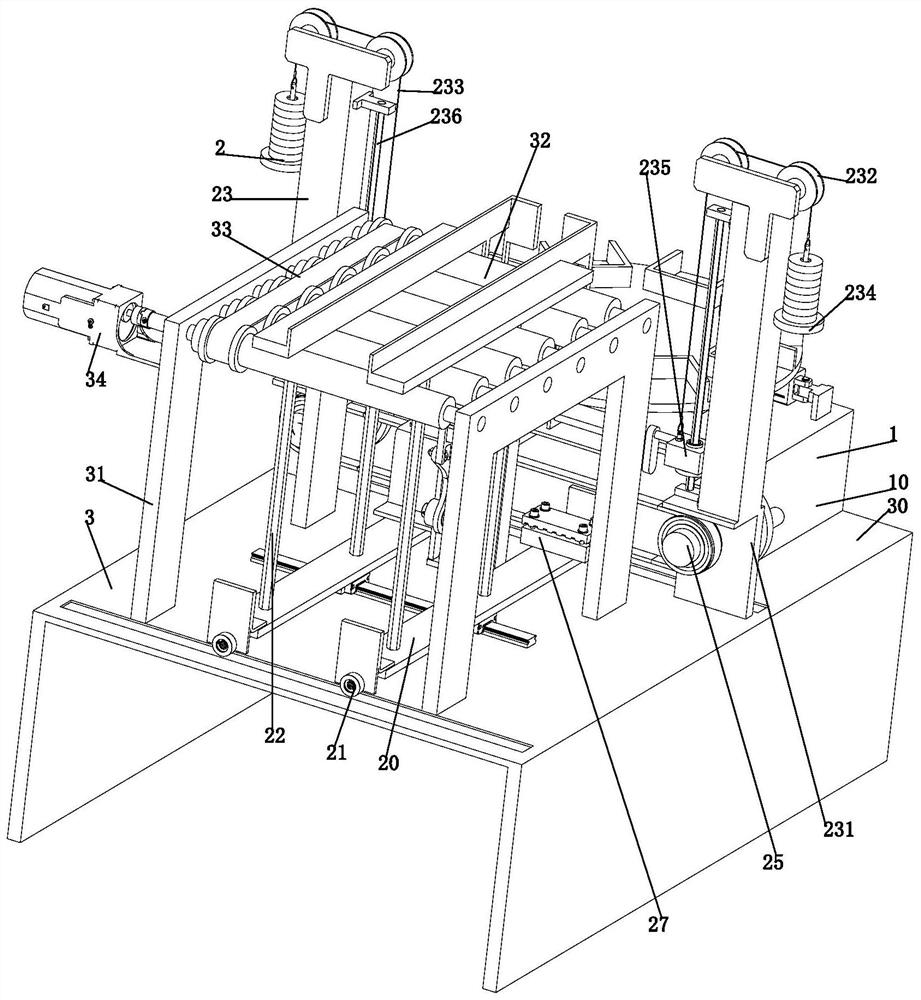

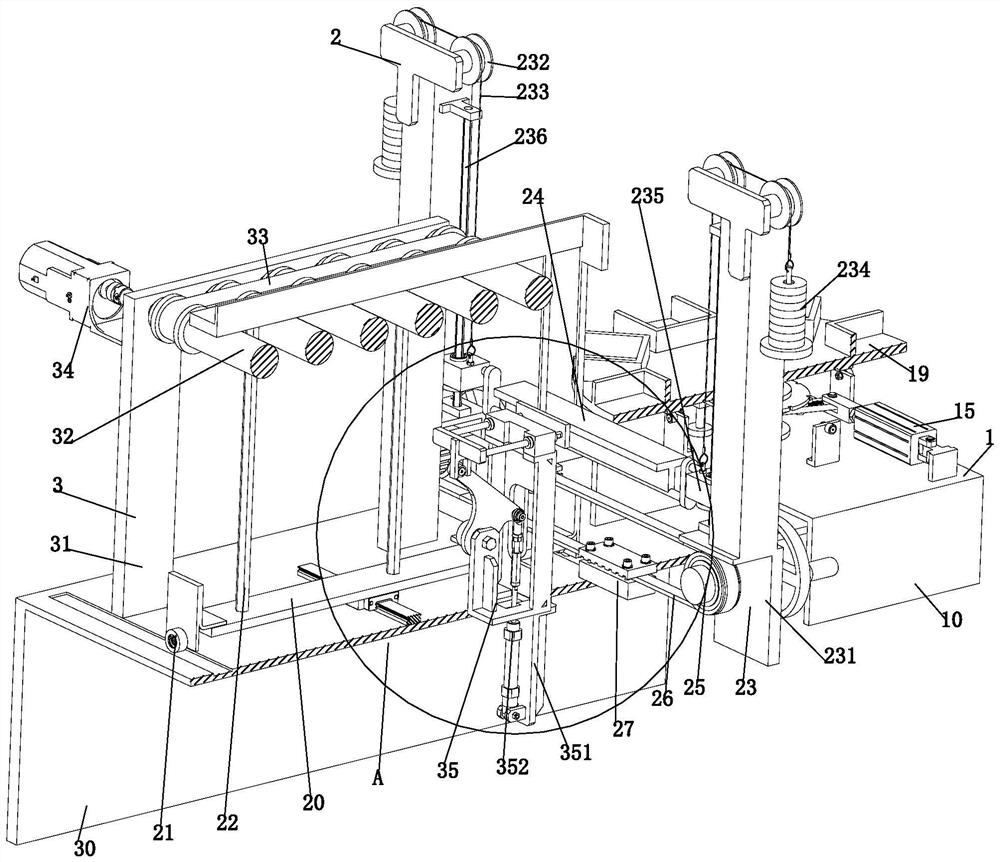

[0025] Such as Figure 1 to Figure 6 As shown, an automatic palletizer for making aluminum foil paper-packed lunch boxes, including an indexing mechanism 1, a lifting mechanism 2 and a pushing mechanism 3, the lifting mechanism 2 is installed on the pushing mechanism 3, and the lifting mechanism 2 It is connected with the push mechanism 3 through sliding fit, and the described indexing mechanism 1 is installed on the push mechanism 3, wherein:

[0026] The indexing mechanism 1 includes an indexing bracket 10, a bearing shaft seat 11, a sliding sleeve connecting rod 12, a ratchet gear 13, an indexing gear 14, an executive master cylinder 15, an executive auxiliary cylinder 16, a ratchet 17, and an index card Claw 18 and indexing turntable 19; Descri...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap