Manual digging pile lifting equipment

A technology of manual hole-digging piles and lifting equipment, which is applied to cranes and other directions, can solve the problems of heavy workload and physical exertion of ground construction personnel, and achieve the effects of protecting safety, saving workers' physical strength, and improving construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

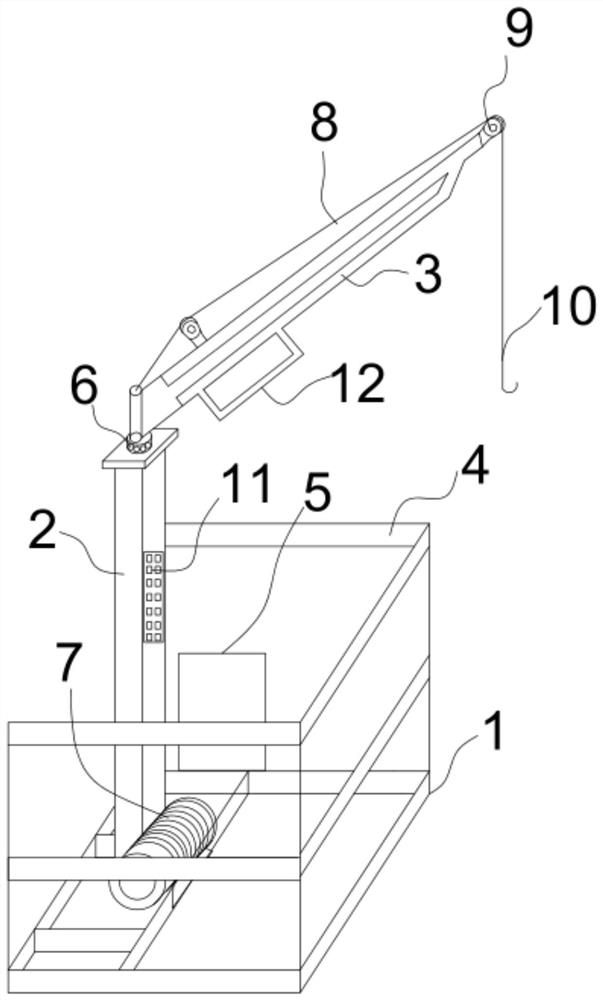

[0017] Such as figure 1 As shown, the present invention provides a kind of manual hole-digging pile lifting equipment, comprising a base 1, a steel wire rope 8, a longitudinal beam 2 and a suspension beam 3, the base 1 is provided with a winch 7 and a power distribution box 5, and the upper part of the base 1 is provided with a fence 4. To protect the safety of operators. The bottom of the longitudinal beam 2 is fixedly connected with the base 1, the surface of the longitudinal beam 2 is provided with a control switch 11, and the control switch 11, the hoist 7 is electrically connected with the distribution box 5, and the electric hoist 7 is used as a power lift, and a control switch is provided to avoid It reduces manual lifting, saves physical strength of workers, and improves construction efficiency. The top of the longitudinal beam 2 is connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com