Room temperature phosphorescent carbon dot composite and preparation method thereof

A technology of room temperature phosphorescence and composites, applied in the direction of fluorescence/phosphorescence, chemical instruments and methods, nano-carbon, etc., can solve the problems of complex steps, complex preparation and processing processes, etc., to achieve enhanced phosphorescence emission, high phosphorescence efficiency, and good room temperature Effect of Phosphorescent Properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Take 10 mL of formamide, mix it with 10 mL of ethylene glycol, and then add 1.6 g of phthalic acid, stir, mix and disperse evenly at room temperature to obtain a reaction solution.

[0035] The above reaction solution was placed in a 40 mL stainless steel autoclave lined with polytetrafluoroethylene, and solvothermally reacted in an oven at 220 ° C for 6 h.

[0036] After the reaction was completed and cooled to room temperature, the obtained solid-liquid mixed product was taken out and vacuum-filtered with a 0.22 μm microporous membrane. After the obtained solid was dried in a drying oven at 60° C., an off-white room temperature phosphorescent carbon dot composite powder solid was obtained.

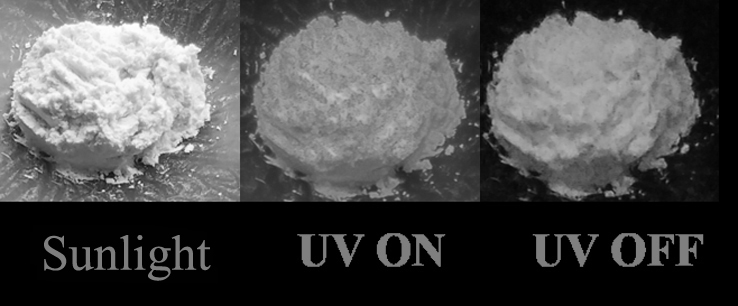

[0037] figure 1 It is the physical picture of the room temperature phosphorescent carbon dot composite prepared above under the irradiation of fluorescent lamp and 365nm ultraviolet lamp respectively, and after stopping the ultraviolet irradiation. The figure shows that the com...

Embodiment 2

[0050] Take 10 mL of formamide, mix it with 10 mL of ethylene glycol, and then add 2.4 g of phthalic acid, stir, mix and disperse evenly at room temperature to obtain a reaction solution.

[0051] The above reaction solution was placed in a 40 mL stainless steel autoclave lined with polytetrafluoroethylene, and solvothermally reacted in an oven at 220 ° C for 6 h.

[0052] After the reaction was completed and cooled to room temperature, the obtained solid-liquid mixed product was taken out and vacuum-filtered with a 0.22 μm microporous membrane. The obtained solid was dried in a drying oven at 60° C. to obtain an off-white powdery solid.

[0053] After irradiating the powdered solid obtained above with a 365 nm ultraviolet lamp for 3-5 seconds, stop the ultraviolet irradiation, and it can be observed that the powdered solid emits green phosphorescence.

Embodiment 3

[0055] Take 10 mL of formamide, mix it with 10 mL of ethylene glycol, and then add 1.6 g of phthalic acid, stir, mix and disperse evenly at room temperature to obtain a reaction solution.

[0056] The above reaction solution was placed in a 40 mL stainless steel autoclave lined with polytetrafluoroethylene, and solvothermally reacted in an oven at 220 ° C for 4 h.

[0057] After the reaction was completed and cooled to room temperature, the obtained solid-liquid mixed product was taken out and vacuum-filtered with a 0.22 μm microporous membrane. The obtained solid was dried in a drying oven at 60° C. to obtain an off-white powdery solid capable of emitting green phosphorescence.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com