Construction road structure on soft soil foundation and construction method

A technology for the construction of access roads and soft soil foundations, applied in soil protection, infrastructure engineering, roads, etc., can solve the problems of low bearing capacity, large demand for sand and gravel, extrusion on both sides, etc., to reduce construction costs, protect Ecological environment, effect of reduced use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

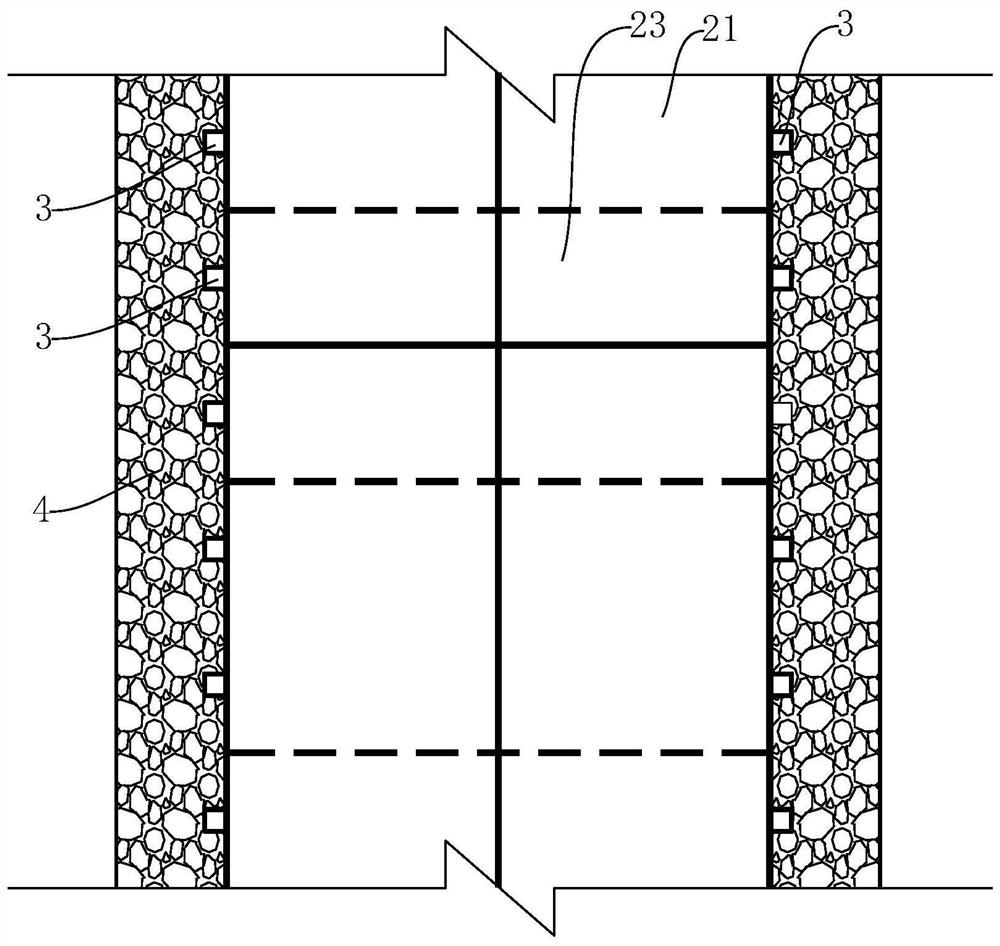

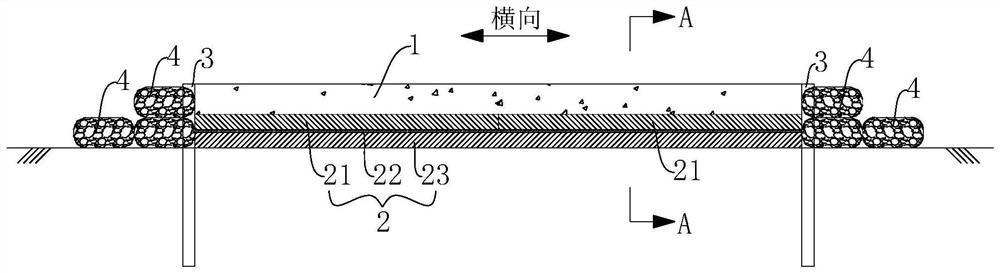

[0040] A construction access road structure on soft ground, such as Figure 1-Figure 3 As shown, it includes light board layer 2 and crushed stone layer 1, light board layer 2 is laid on the lower layer of gravel layer 1, bagged sand pebbles 4 and several fixed stakes 3 are arranged on both sides of the construction access road, bagged sand Pebbles 4 and fixed stakes 3 are arranged along the line direction.

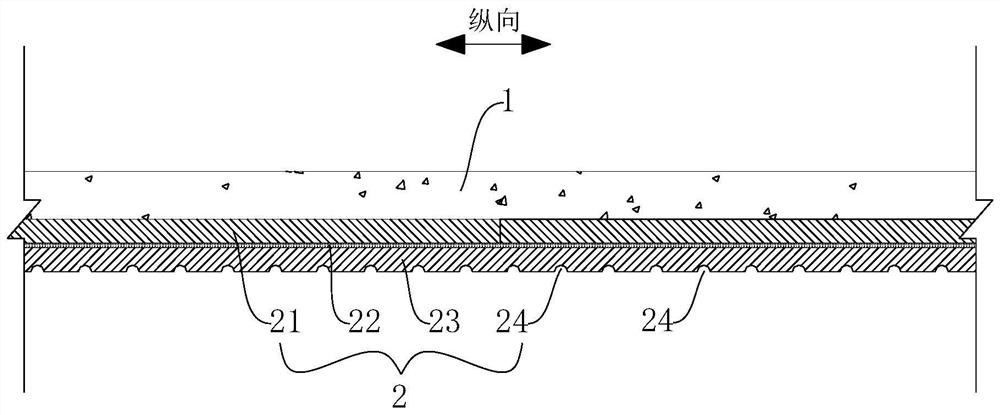

[0041] Specifically, the lightweight board layer 2 includes several rigid foam boards, and the several rigid foam boards are arranged along the line direction. The planar shape of each rigid foam board is a rectangle. The light board layer 2 includes two layers, the upper and lower layers are assembled by several rigid foam boards, the length direction of the upper rigid foam board is arranged along the longitudinal direction of the line, that is, the longitudinal rigid foam board 21; The length direction of the foam board is arranged along the transverse direction of t...

Embodiment 2

[0056] Based on embodiment 1, present embodiment also provides a kind of construction method of the construction access road on the soft ground, comprises the following steps:

[0057] S1. Level the plain ground and lay horizontal rigid foam boards 23, which should be stacked neatly when laying;

[0058] S2. Drive in fixed wooden piles 3 at intervals of 2m along the longitudinal direction of the line. The fixed wooden piles 3 penetrate the extremely soft soil foundation. When the extremely soft soil foundation is thick and difficult to penetrate, the depth of insertion into the extremely soft foundation should be greater than 3m;

[0059] S3, laying the composite geomembrane 22, should be paved evenly when laying, pay attention to avoid sharp objects piercing the composite geomembrane 22, before laying the upper vertical rigid foam board 21, the construction machinery must not directly roll the composite geomembrane 22;

[0060] S4. Lay the vertical rigid foam boards 21. When ...

Embodiment 3

[0064] Based on the above-mentioned embodiments 1-2, this embodiment provides an example of calculating the thickness of the rigid foam board for the construction access road structure on the above-mentioned soft soil foundation:

[0065] Given: the wheel load F of the construction machinery is 120kN, the wheel ground width a is 0.2m, the wheel ground length b is 0.6m, the thickness of the gravel cushion, the pressure diffusion angle of the gravel cushion is 30°, and the pressure diffusion of the rigid foam board angle is 45°, and the bearing capacity of the soft soil foundation is 80kPa, then it can be known that:

[0066] a 1 =a+2d 1 tanθ 1 =0.2+2×0.3×tan30°=0.55m

[0067] b 1 =b+2d 1 tanθ 2 =0.6+2×0.3×tan30°=0.95m

[0068]

[0069] get d 2 ≤0.25m.

[0070] That is, the total thickness of the rigid foam board is greater than 0.25m, that is, the thickness of the longitudinal rigid foam board 21 and the transverse rigid foam board 23 is greater than 0.125m.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Bursting strength | aaaaa | aaaaa |

| Peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com