Locking structure

A technology of locking structure and stop plate, applied in the direction of functional valve type, control valve, safety valve, etc., can solve problems such as automatic failure of fireproof check valve, and achieve the effect of reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

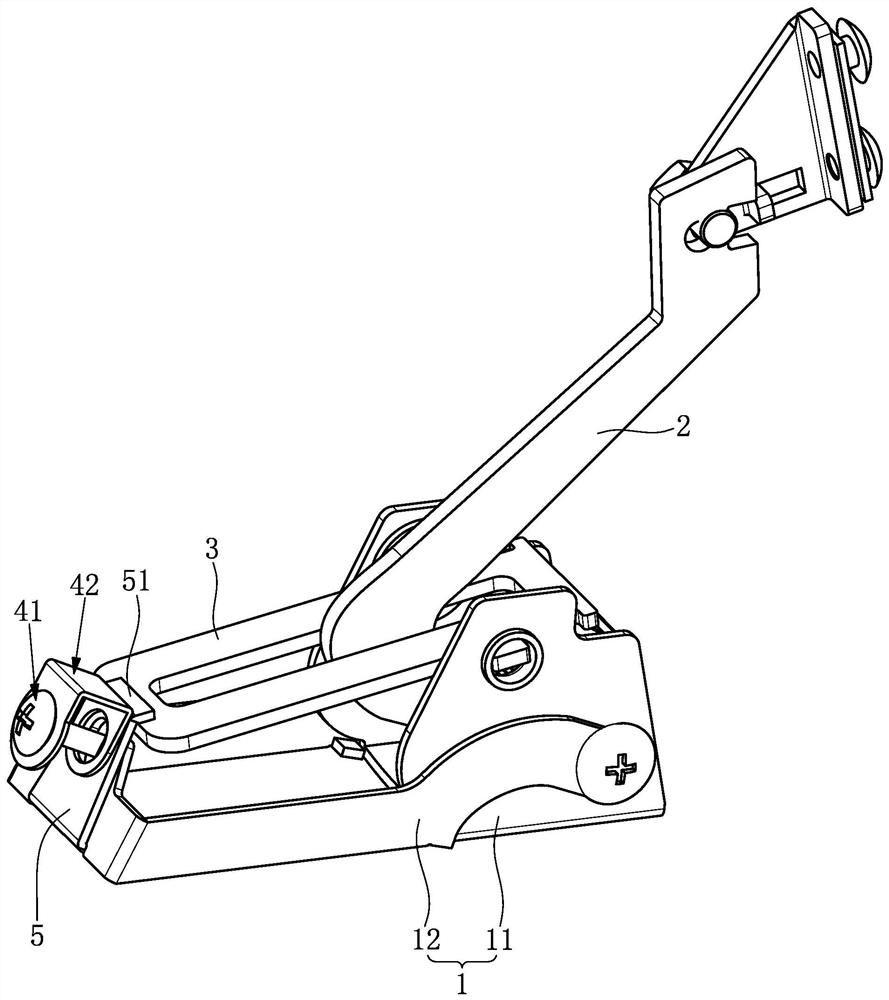

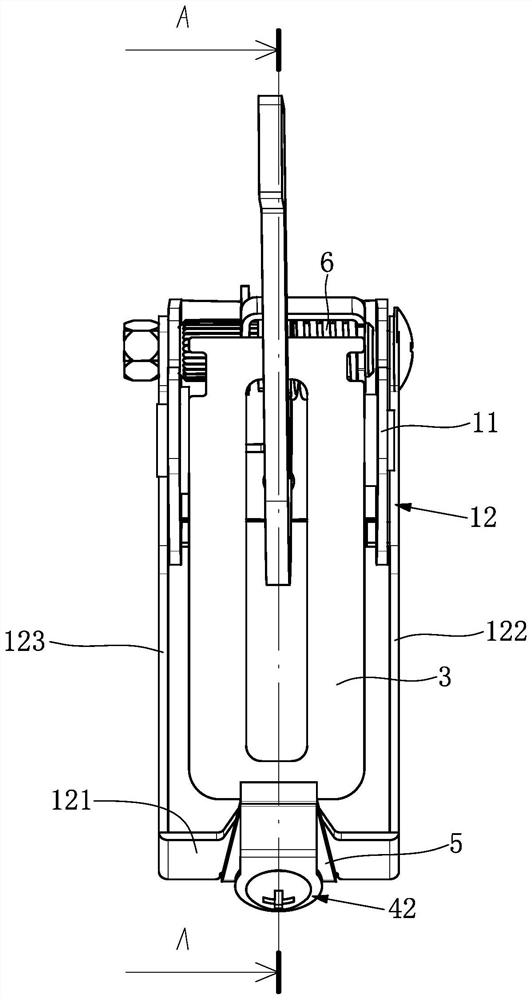

[0028] see figure 1 , the locking structure includes a base 1, a connecting rod 2, an elastic element and a dial 3, the connecting rod 2 and the dial 3 are rotatably arranged on the base 1, one end of the elastic element is arranged on the base 1, and the other end of the elastic element is One end is arranged on the paddle 3 and is used to drive the paddle 3 to rotate relative to the base 1 .

[0029]It should be noted that: the existing elastic element is a torsion spring, and the torsion spring is sleeved on the rotating shaft of the plectrum 3. When the torsion spring is sleeved on the rotating shaft of the plectrum 3, one end of the torsion spring is fixed on the On the base 1 , the other end of the torsion spring abuts against the upper surface of the plectrum 3 . Since the elastic element is not the focus of the present invention, this embodiment does not specifically limit the structure of the elastic element and the connection structure between the elastic element an...

Embodiment 2

[0043] The difference from the first embodiment is that the structure of the fuse assembly is improved in this embodiment.

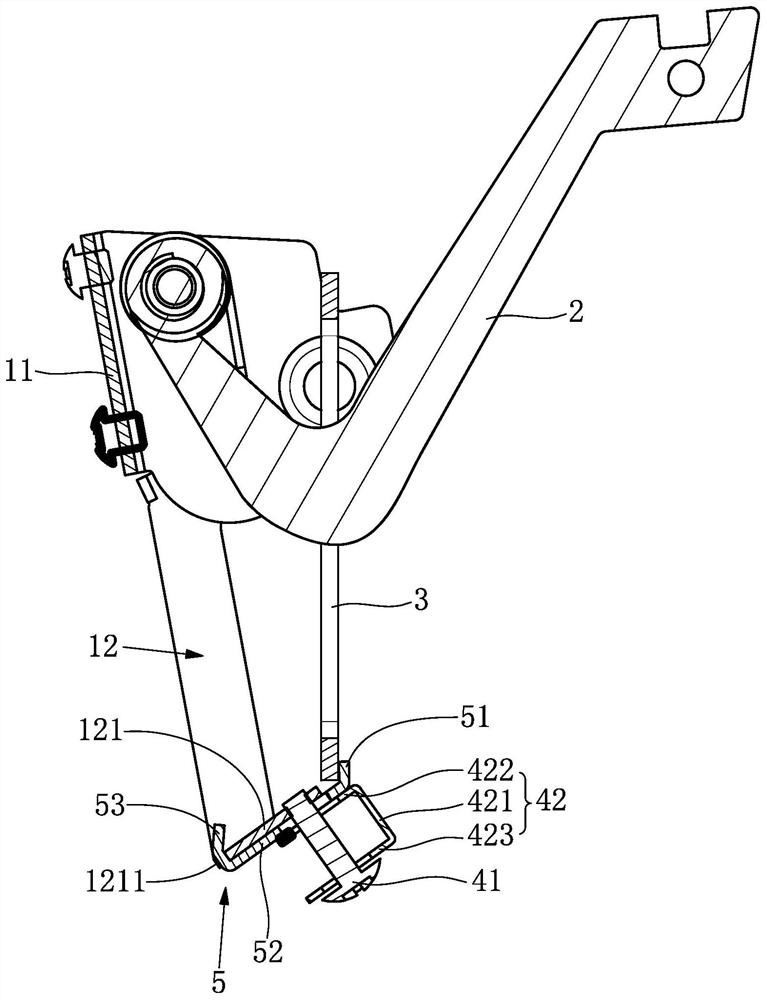

[0044] see Figure 4 , in this embodiment, the fuse assembly includes at least one fuse piece 42 and at least one fuse ring 43, and the fuse piece 42 includes a first fuse part 422, a second fuse part 423 and is used to control the stop plate 5 on the fastening mechanism 41 The third fuse part 421 in the axial movement range, the first fuse part 422 and the second fuse part 423 are respectively arranged on the fastening mechanism 41, and the third fuse part 421 is used to connect the first fuse part 422 and the second fuse part 423 , the fuse ring 43 is clamped between the first fuse part 422 and the second fuse part 423 .

Embodiment 3

[0046] The difference from the first embodiment is that the structure of the fuse assembly is improved in this embodiment.

[0047] see Figure 5 , in this embodiment, the fuse assembly includes at least one fuse ring 43, the fuse ring 43 is provided with a mounting hole, the fuse ring 43 is sleeved on the fastening mechanism 41 and used to control the axial movement of the stop plate 5 range of motion.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com