Patents

Literature

40results about How to "Easy to change the distance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

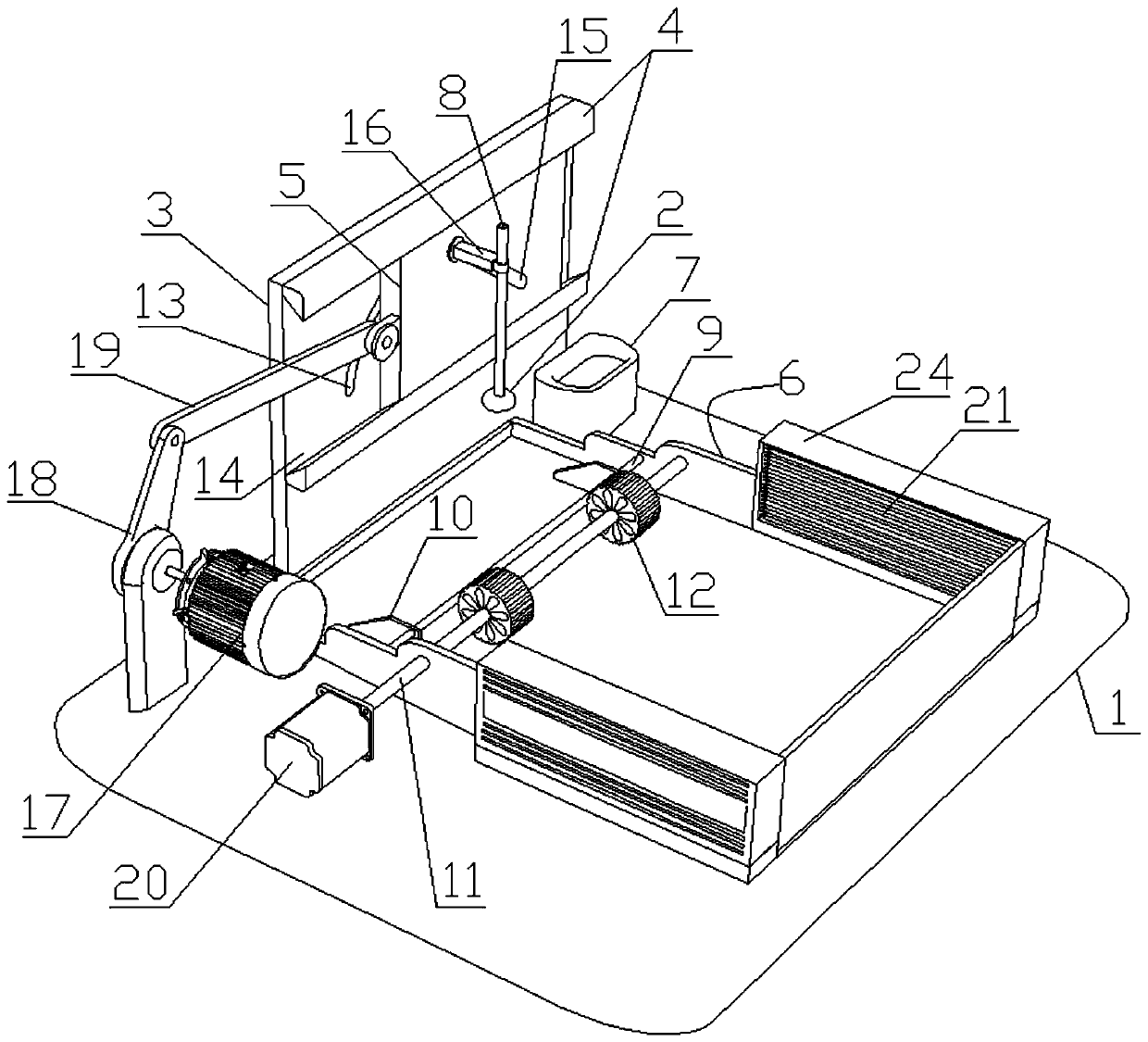

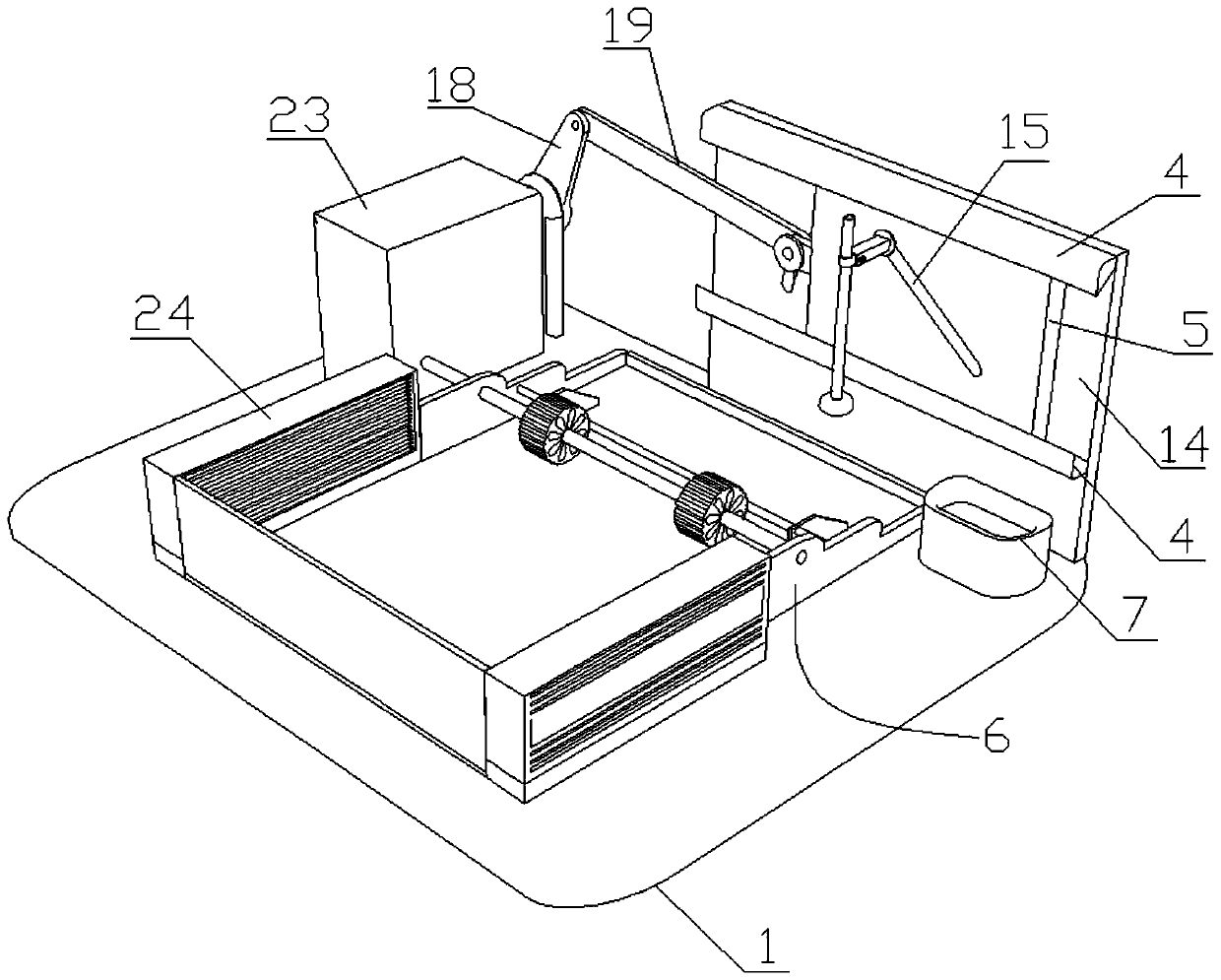

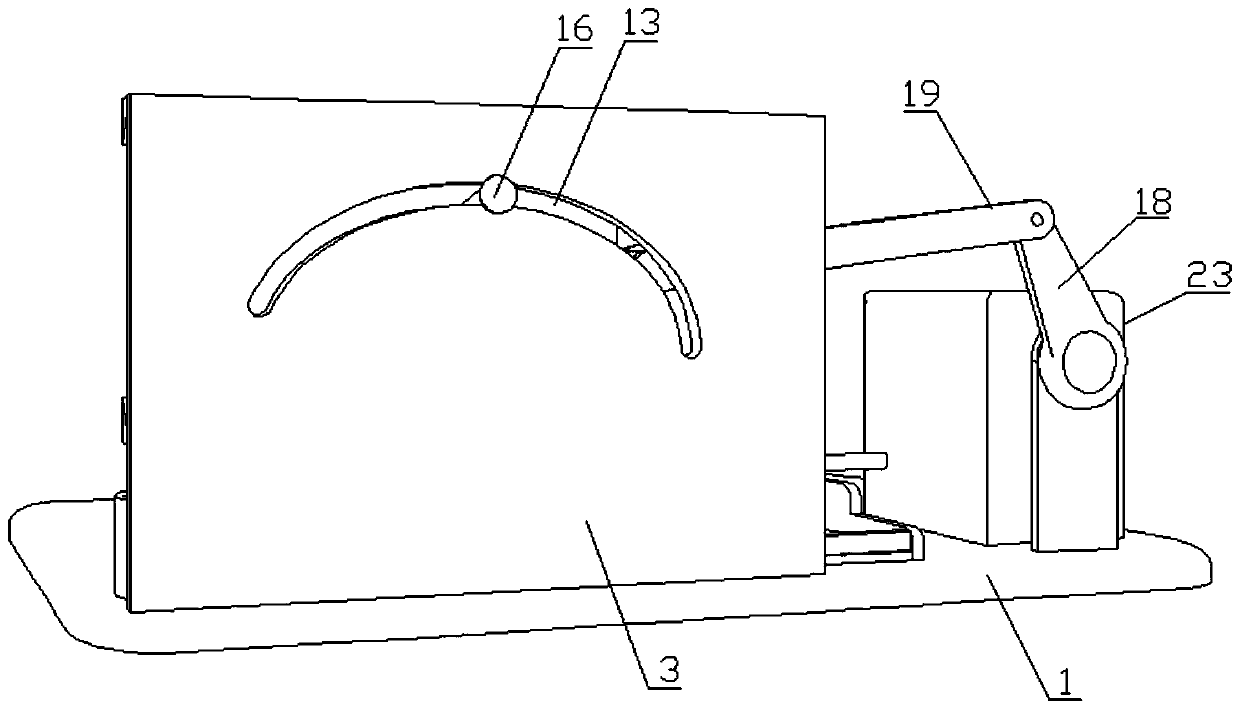

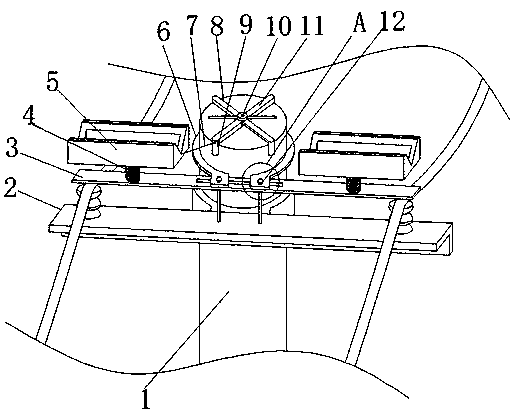

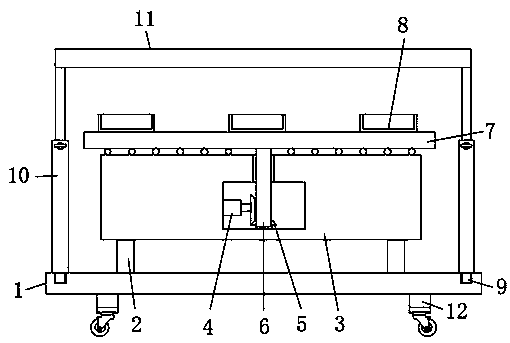

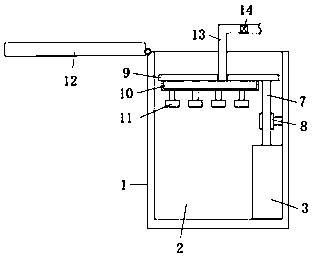

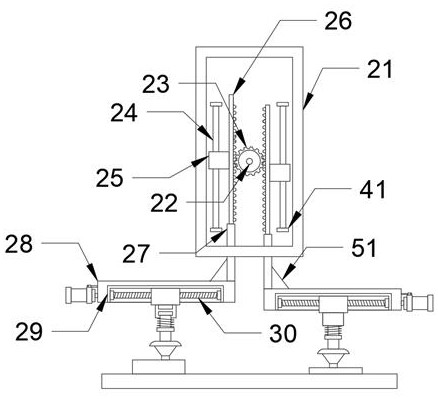

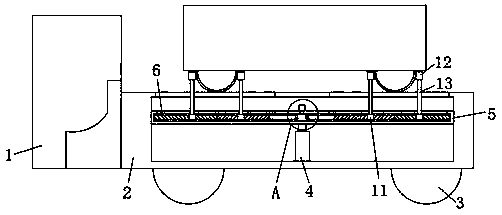

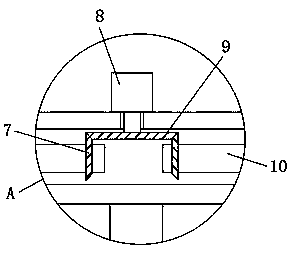

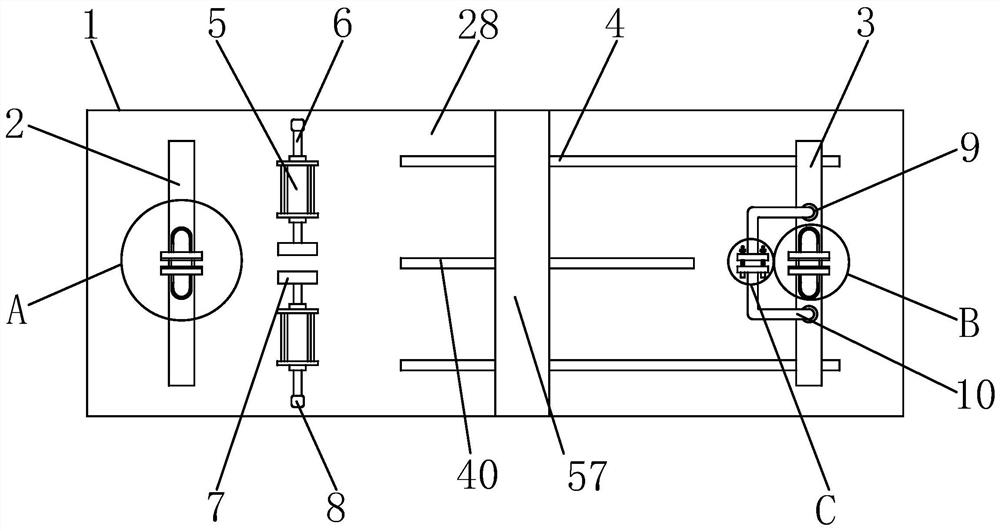

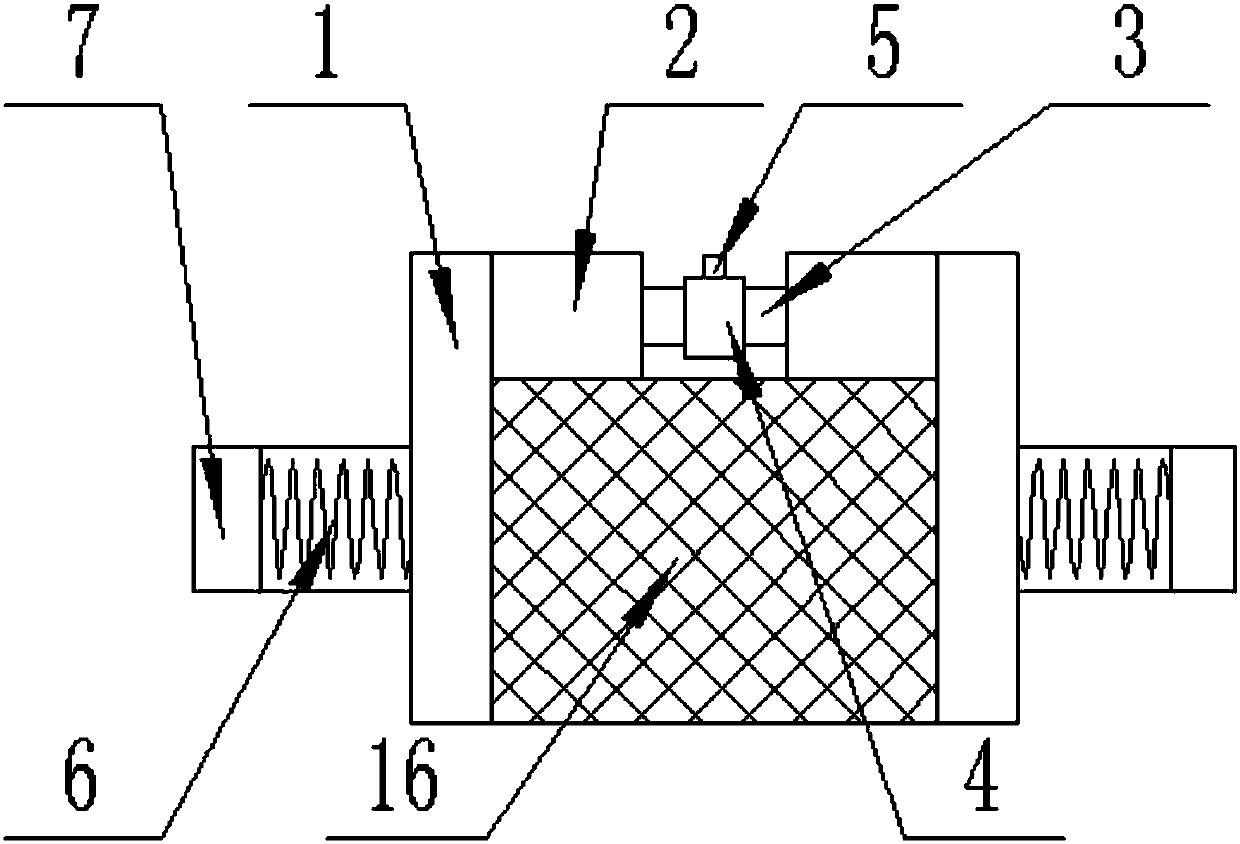

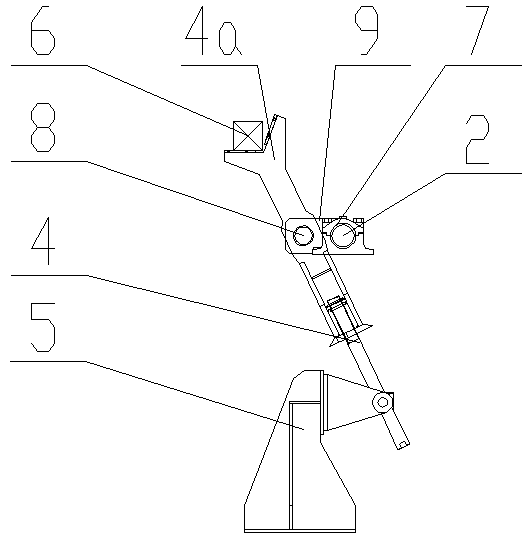

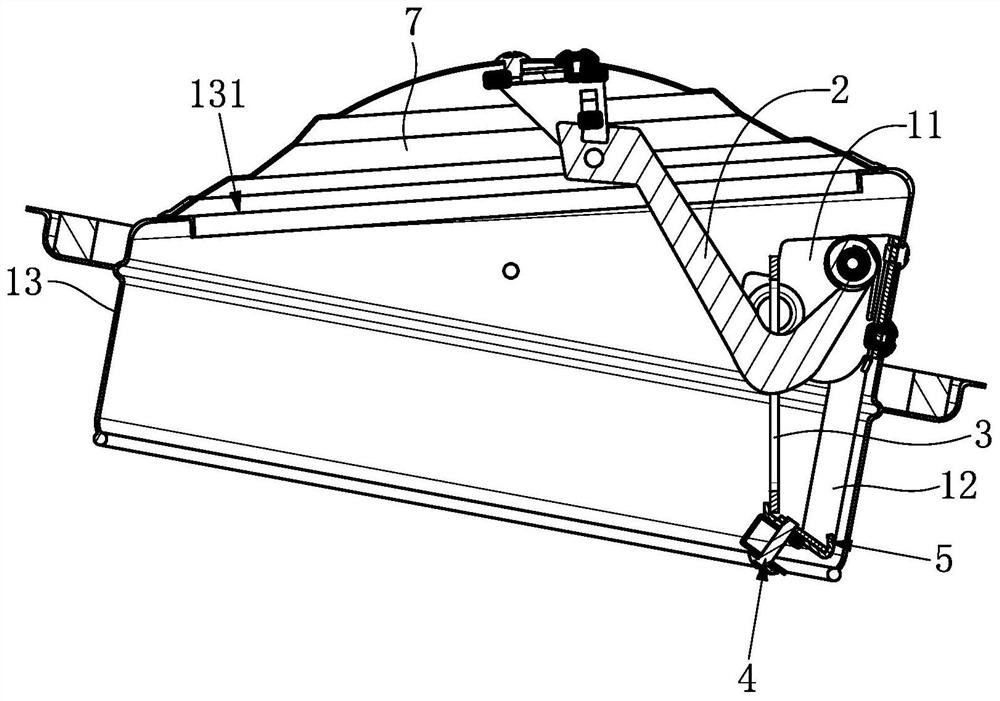

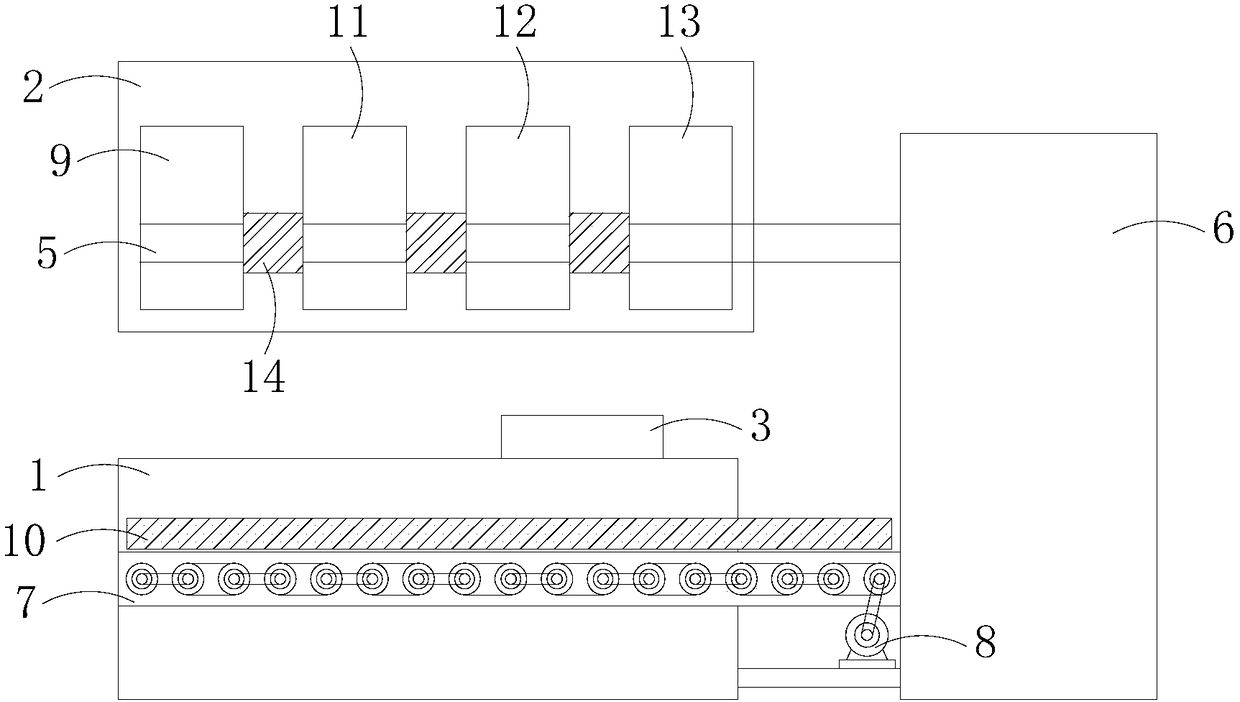

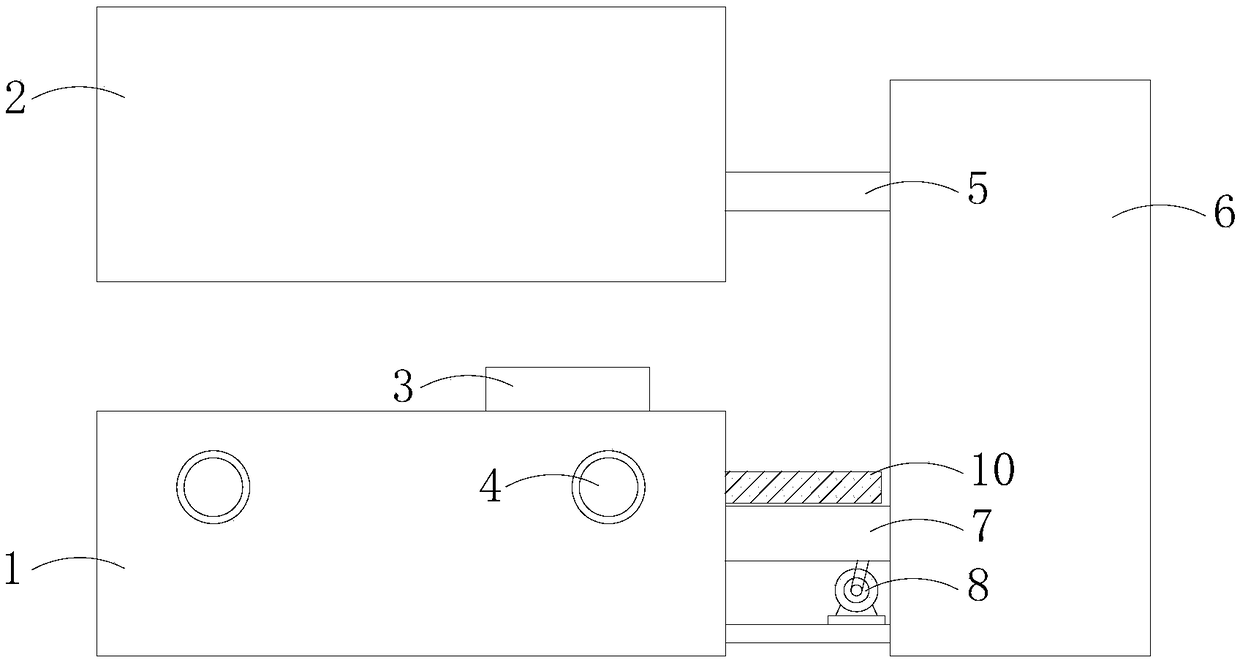

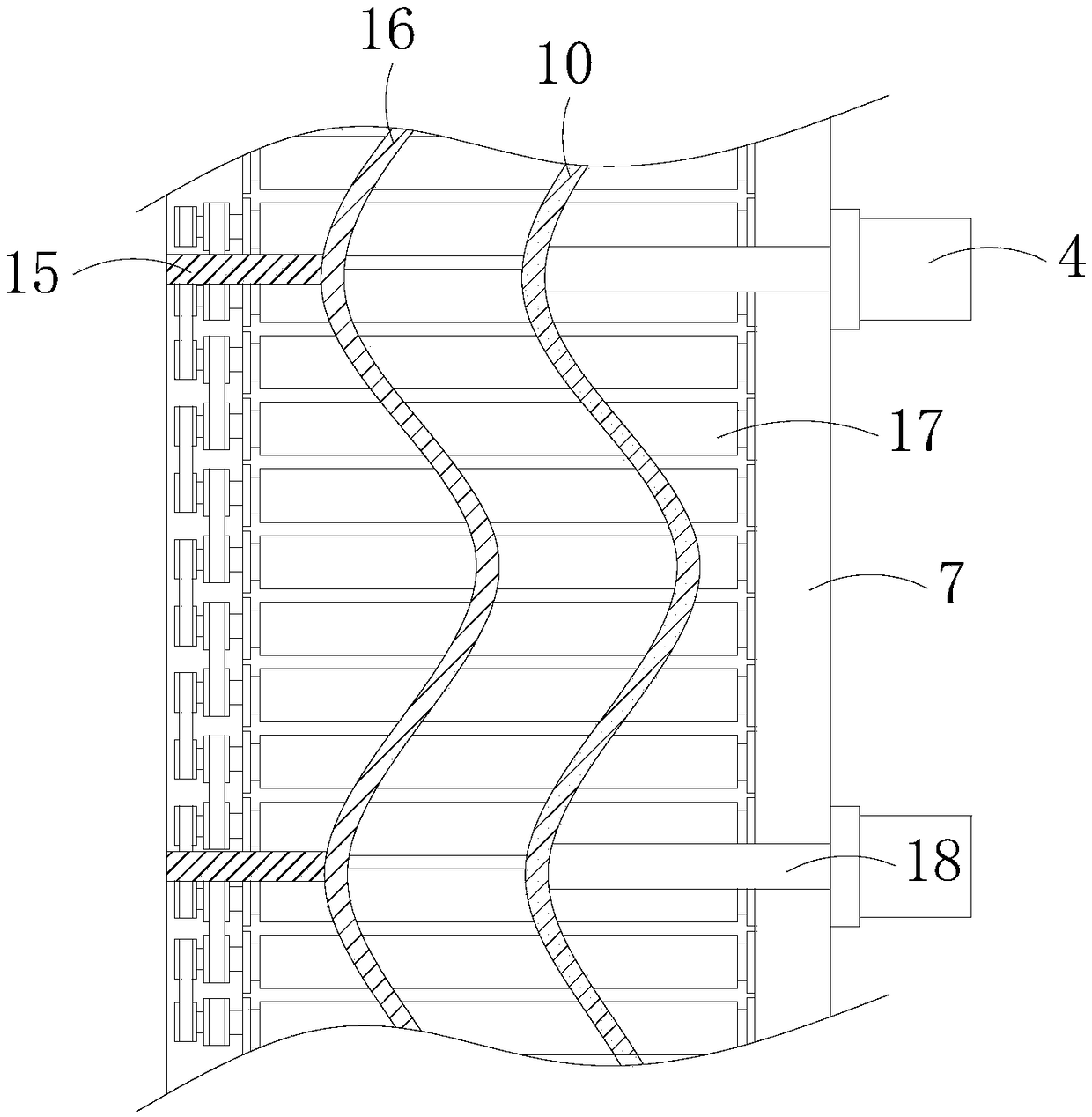

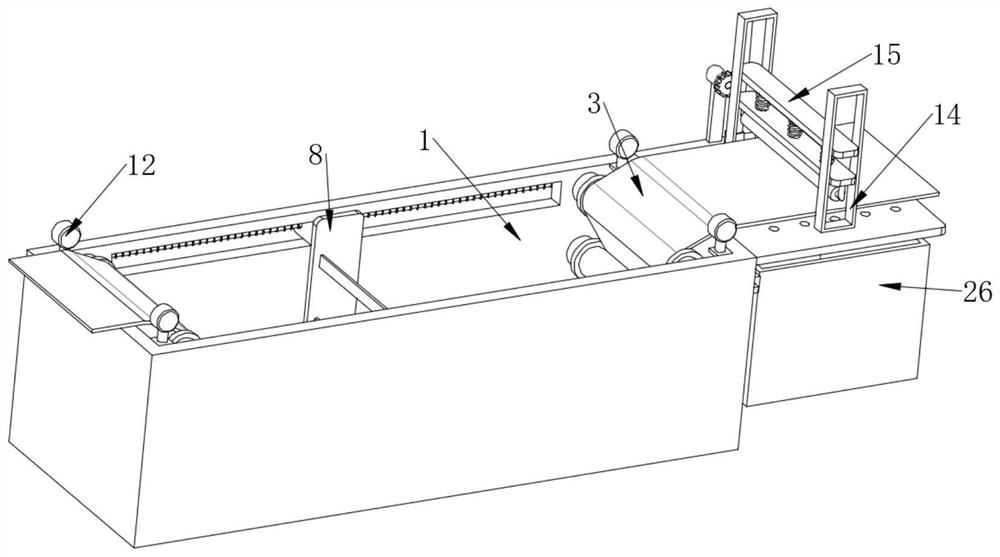

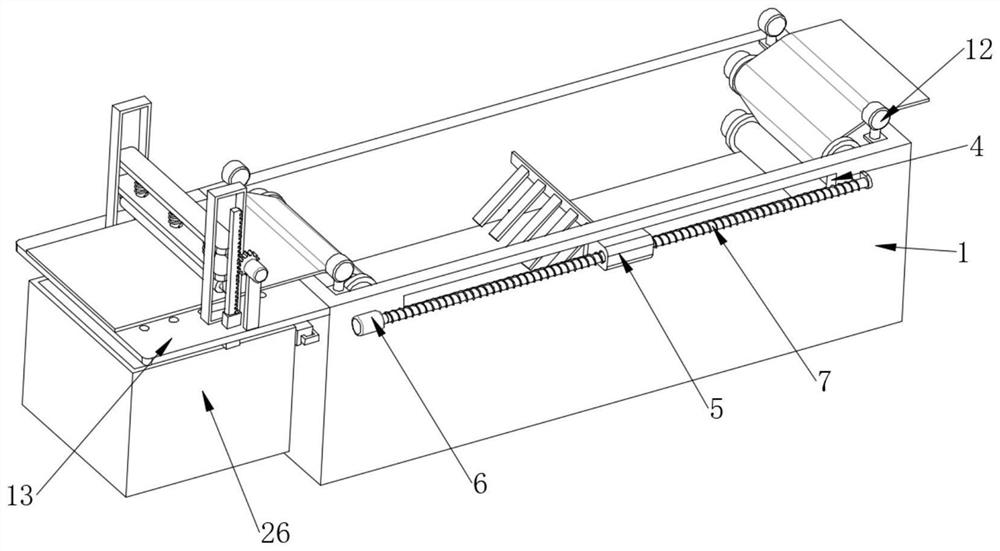

Automatic seal machine

The invention discloses an automatic seal machine. A supporting vertical plate is fixedly connected to the front end of a supporting bottom plate, and the middle of the supporting vertical plate is provided with an arc-shaped through groove; a pair of guide rails are fixedly connected with the supporting vertical plate in a spaced mode, and a transverse slide groove is formed between the two guiderails; a slide plate is transversely and slidably arranged in the transverse slide groove and provided with an inclined through groove with the left side higher than the right side; a bearing frame is fixedly connected to an upper end surface of the supporting bottom plate; an inkpad box is fixedly connected to the right side of the front end of the bearing frame; a connection rod is vertically arranged on the rear side of the supporting vertical plate, the lower end of the connection rod is fixedly connected with the upper end of a seal, the upper portion of connection rod is vertically andfixedly connected with a guide transverse beam, and the guide transverse beam is in sliding fit with the inclined through groove and the arc-shaped through groove; an output shaft of a first driving motor is vertically and fixedly connected with one end of a crank, the other end of the crank is hinged to one end of a rocker, and the other end of the rocker is hinged to the left end of the slide plate; and the front end of the interior of the bearing frame is provided with a pair of paper baffles adjustable in distance and further provided with a pair of paper rubbing wheels driven by the motor. The automatic seal machine can automatically achieve large-batch seal operation.

Owner:XUZHOU UNIV OF TECH

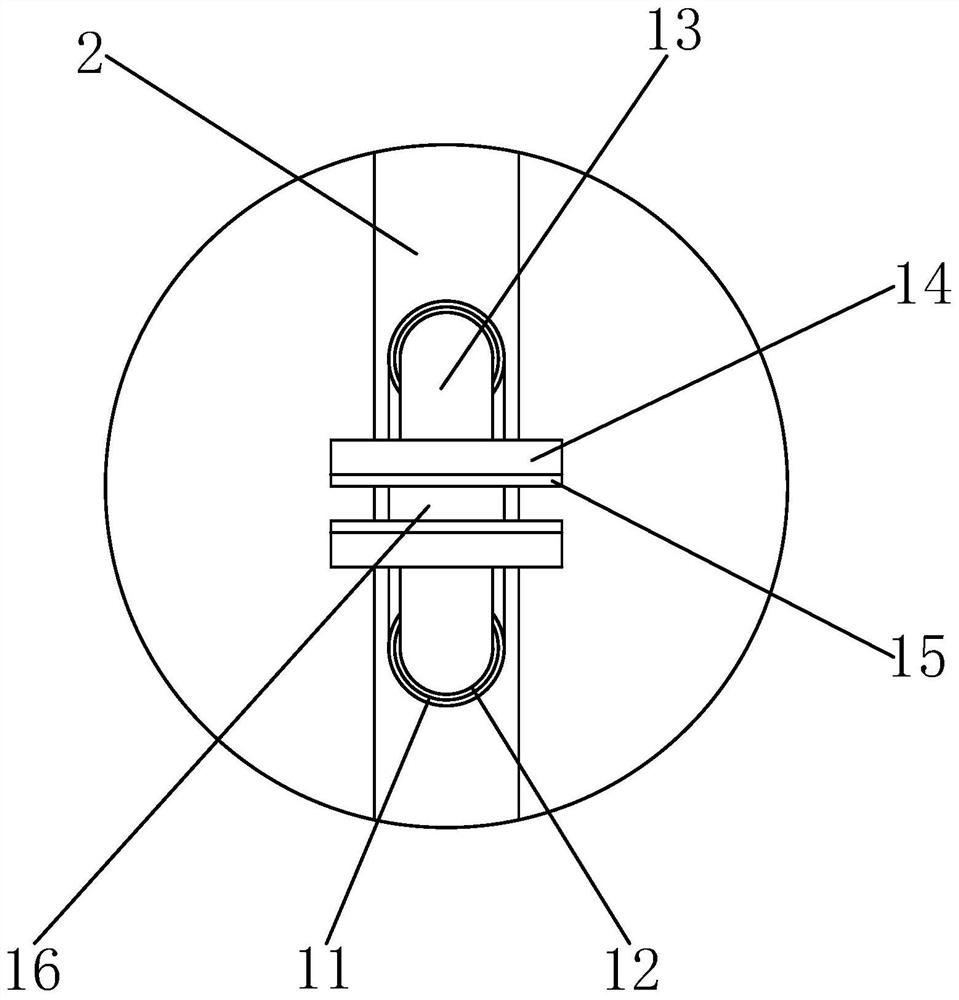

Elastic bird repelling device for telegraph pole

InactiveCN111011351AAvoid gatheringAvoid random movementSuspension arrangements for electric cablesAnimal repellantsMedical equipmentEngineering

The invention belongs to the technical field of medical equipment, and particularly relates to an elastic bird repelling device for a telegraph pole. In view of the problem that the effect of a wind power bird repelling device is greatly reduced in a breezy or windless environment, the following scheme is proposed: the device comprises a telegraph pole and an electric wire bracket, the electric wire bracket is arranged on one side of the telegraph pole, two fixing rings are arranged at the outer side of the telegraph pole, the two fixing rings are connected with a fixing plate through bindingbolts, support springs are welded on both sides of the top end of the fixing plate, a moving body is welded at the top end of each support spring, and a first groove is arranged at the top end of eachmoving body. According to the invention, the moving bodies are out of balance due to the weight of wind and birds when the moving bodies are blown by the wind or birds stand on two sides of each moving body, and then the support springs start to swing to repel the birds on the moving bodies; meanwhile, through the swing of the moving bodies, sound-producing tubes hit sound-producing plates to make a sound, sound-producing through-holes enable the sound to be fully gathered, and the sound is directly transmitted to the feet of the birds to repel the birds.

Owner:HUBEI UNIV OF TECH

Communication cable fixing device

The invention discloses a communication cable fixing device, which comprises a base, a support rod is fixed on one side of the top of the base, a top plate is fixed on the top of the support rod, a groove is opened on the bottom of the top plate, and a threaded sleeve is horizontally arranged in the groove , and the top of the worm extends above the top of the top plate, and is connected with a handle, both sides of the threaded sleeve are threaded with movable blocks, the two movable blocks are hinged with connecting rods, and the bottom of the two connecting rods is set There is a roller, and rotating rods are installed on both sides of the drum, and a mounting block is fixed on the side of the two rotating rods away from each other, and both rotating rods extend to the inside of the mounting block, and the one far away from the support rod One side of the mounting block is welded with a disc handwheel. The invention has the advantages of simple structure, reasonable design, convenient fixing of cables, good fixing effect, preventing damage of cables, saving a lot of space, simple operation and easy popularization.

Owner:成都聚慧讯科技有限公司

Wall-mounted table lamp

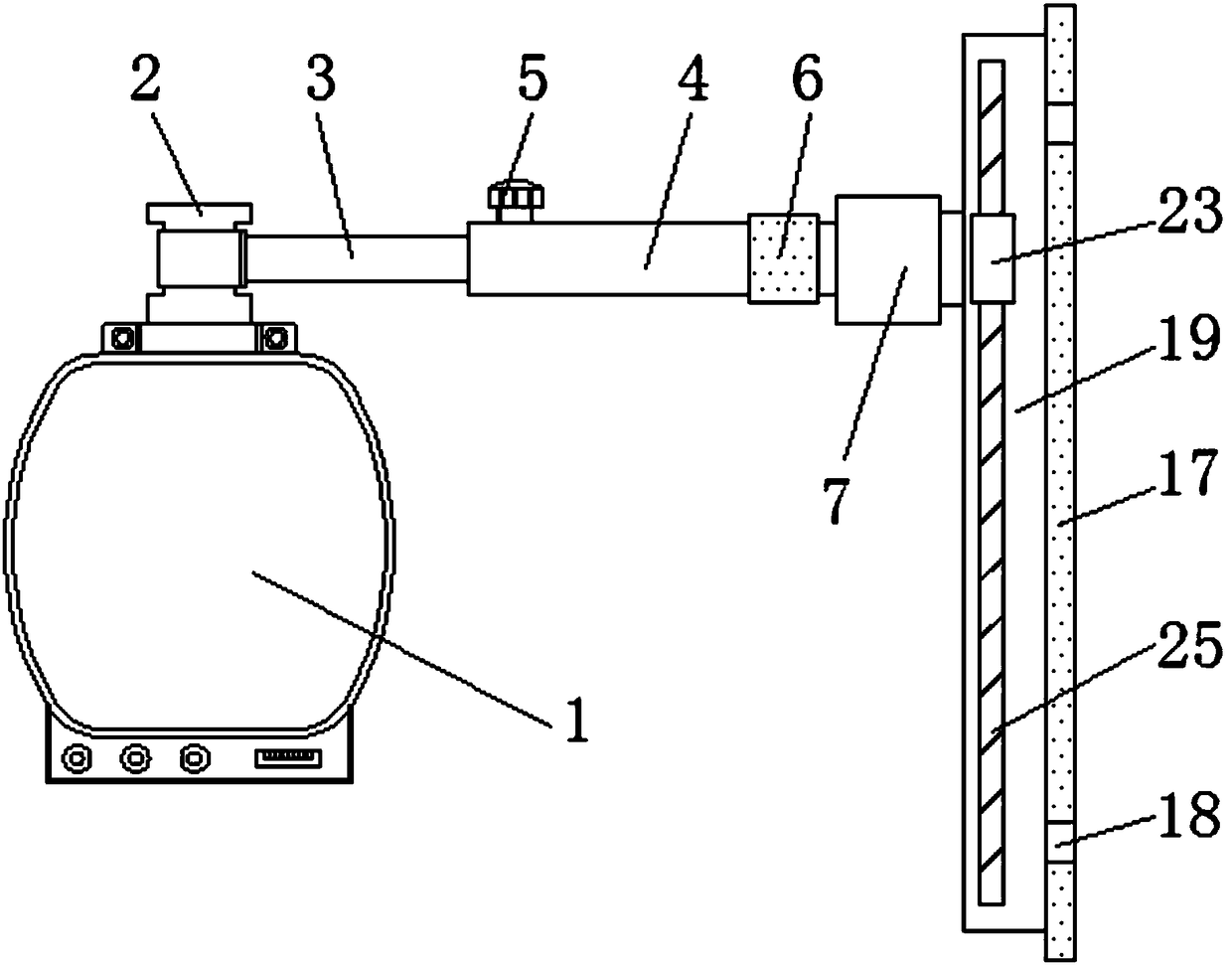

InactiveCN108332112AChange horizontal positionImprove stabilityLighting support devicesFixed installationWall mountComputer engineering

The invention provides a wall-mounted table lamp. The wall-mounted table lamp mainly comprises a lamp body, a storage sleeve, a mounting bottom plate and a second reset spring. A joint is arranged above the lamp body, and the joint penetrates through the surface of the left end of a load-bearing rod. The load-bearing rod is arranged on the left side of the storage sleeve, and an adjustment bolt isarranged on the upper portion of the storage sleeve. Bolt holes and a storage box are arranged on the surface of the mounting bottom plate, and the bolt holes are formed in the two sides of the storage box. First clamping blocks are arranged on the two sides of the inner wall of the storage box. Balance plates are connected between the two sides of the second reset spring. A pressing block penetrates through sliding grooves, and the sliding grooves are located on the both sides of the storage box. According to the wall-mounted table lamp, the length between the load-bearing rod and the storage sleeve can be changed to adjust the horizontal position of the suspension of the lamp body, the first clamping block and a second clamping block are separated when two extrusion blocks are pinched,then upper and lower sliding can be carried out, so that the height of the protective plate is changed.

Owner:广州元坤新材料有限公司

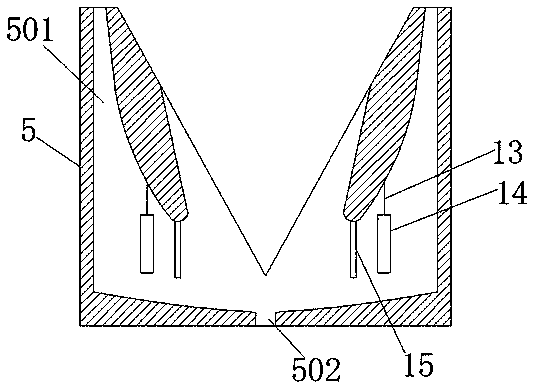

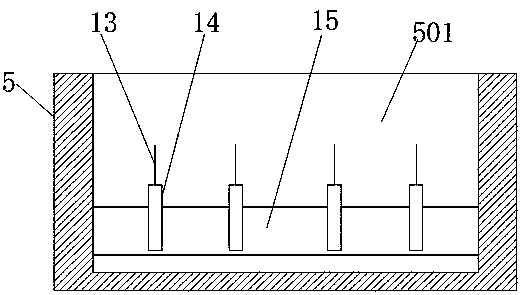

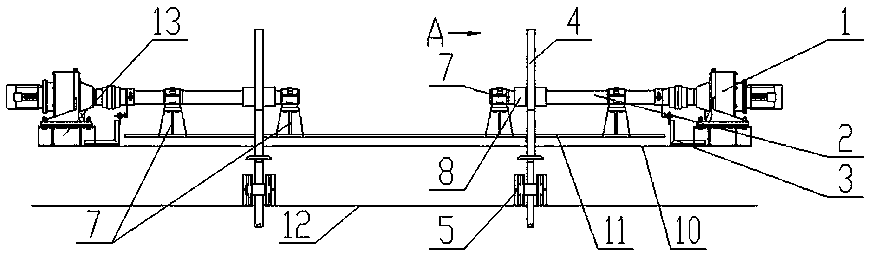

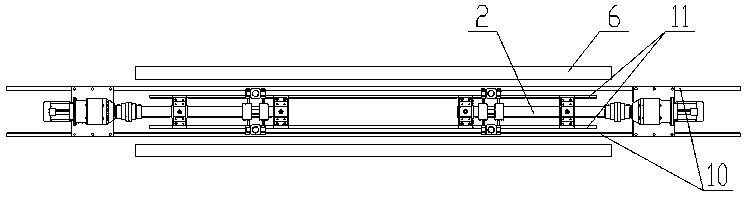

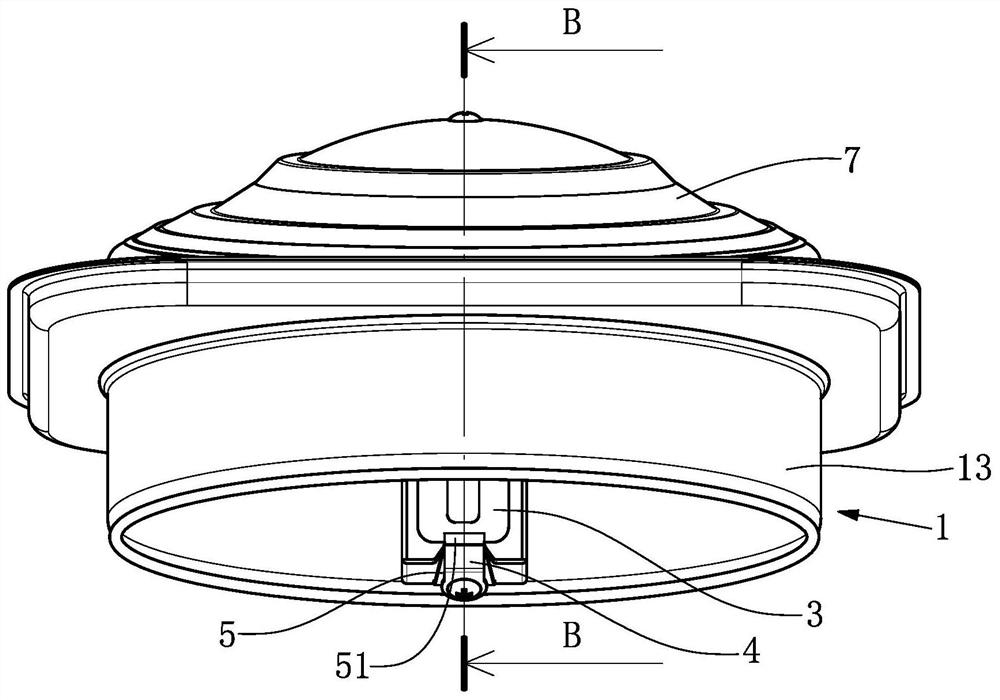

Self-shaping method for gas-smelted quartz glass ingots

ActiveCN108793692AEasy to change the distanceAchieve physical contactGlass shaping apparatusGlass productionMaximum diameterIngot

The invention relates to a self-shaping method for gas-smelted quartz glass ingots. The self-shaping method comprises the following steps: adding a silicon material into a quartz beating machine, melting and flowing into a furnace chamber of a smelting furnace under the action of high temperature oxyhydrogen flame, carrying out deposition heap-up dissolving operation, forming concentric circle molten glassy-state cylindrical quartz glass ingots with different diameters at different deposition heights in a deposition growth and flowing process; and when the height of the ingots is stacked and grows to every 20 mm-50 mm, beginning to self-shape, allowing a quartz flame head and the molten glassy-state cylindrical quartz glass ingots together to move to the inner wall of the furnace chamber of the smelting furnace in a radial movement manner, making the maximum diameter of the molten glassy-state cylindrical quartz glass ingots produce friction with the inner wall of the furnace chamber,producing deformation, and making the product external dimension meet upper-and-lower equal diameter requirements in the height range, so as to obtain the product. The friction force between objects is used for shaping the appearance size of the product, the shape of the quartz glass ingots can be precisely controlled, the appearance defects of the product can be reduced, the efficiency can be improved and the production cost can be reduced.

Owner:江苏省晶瑞石英工业开发研究院有限公司

Supporting frame for strawberry planting

PendingCN108633558AAvoid sun exposureEasy to growReceptacle cultivationPlant protective coveringsDrive motorArchitectural engineering

Owner:贵州荣兴生态农业科技有限公司

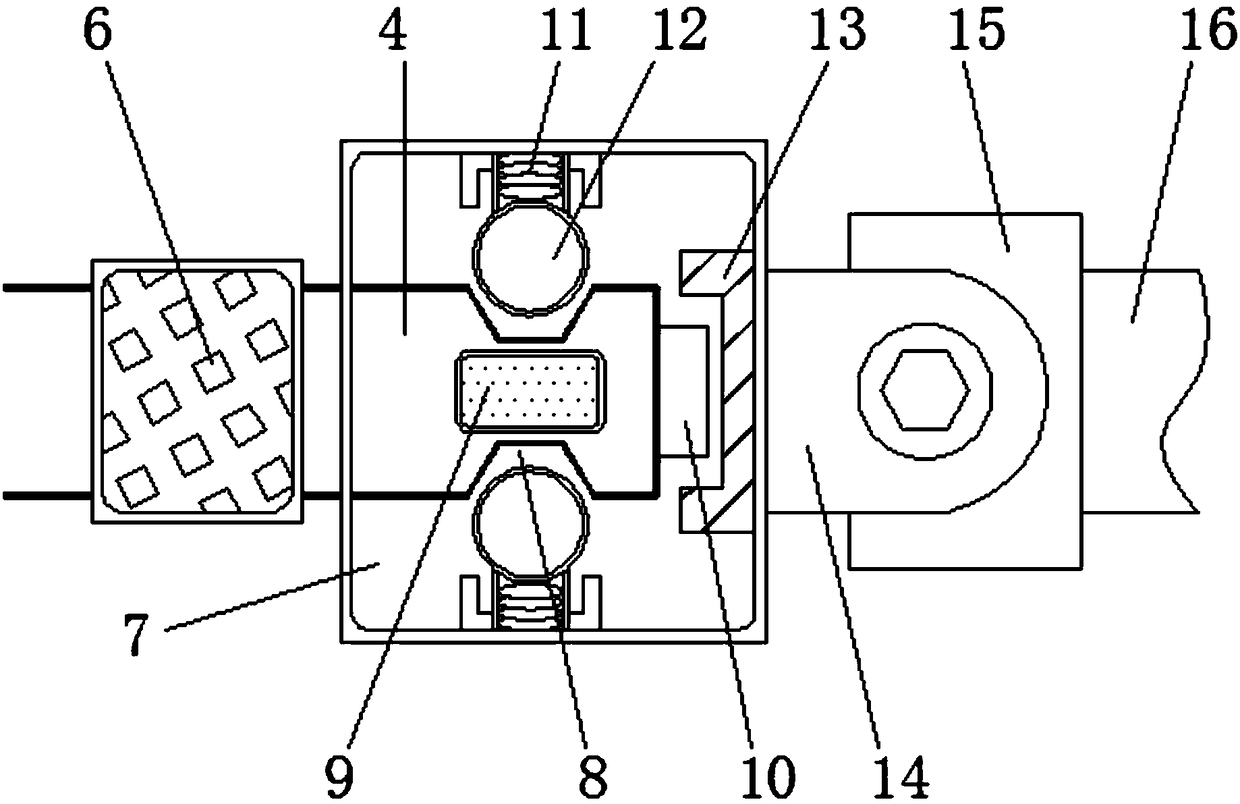

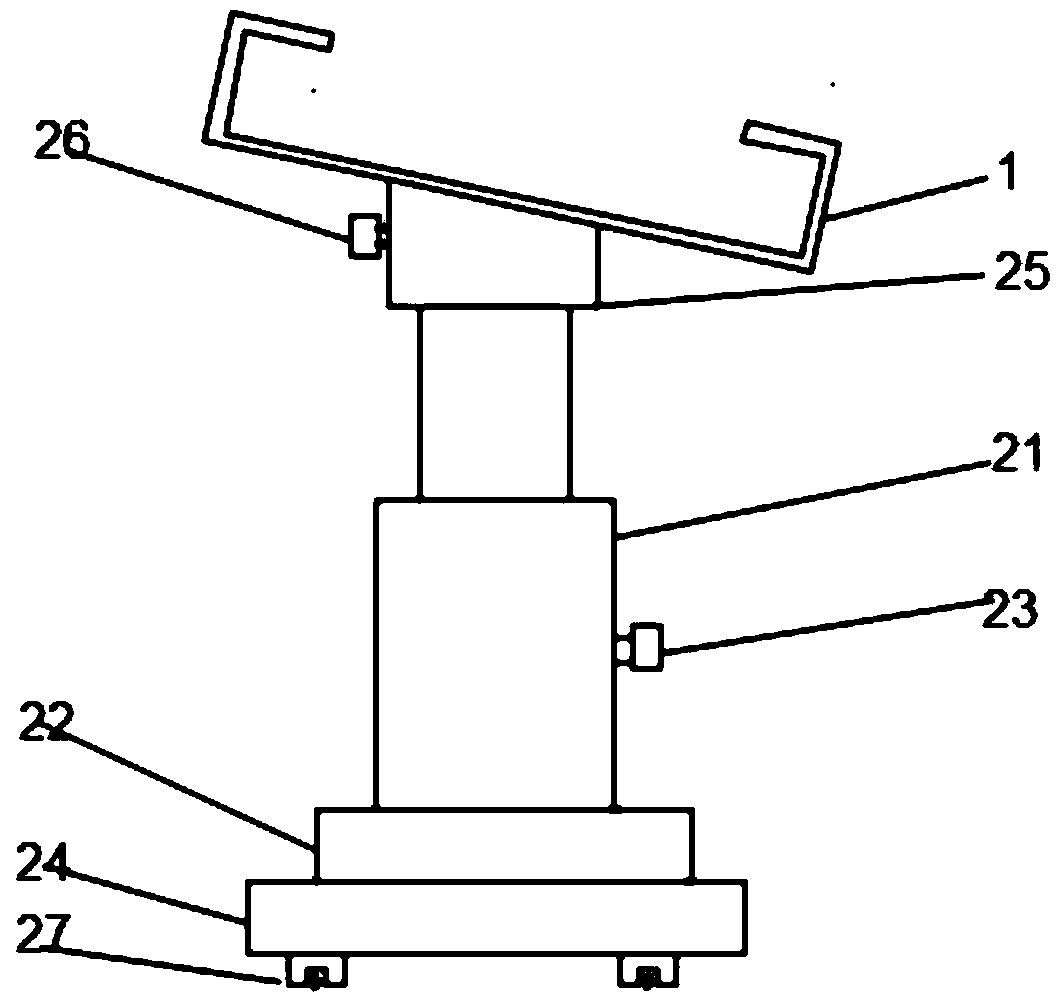

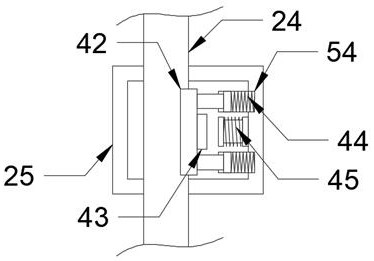

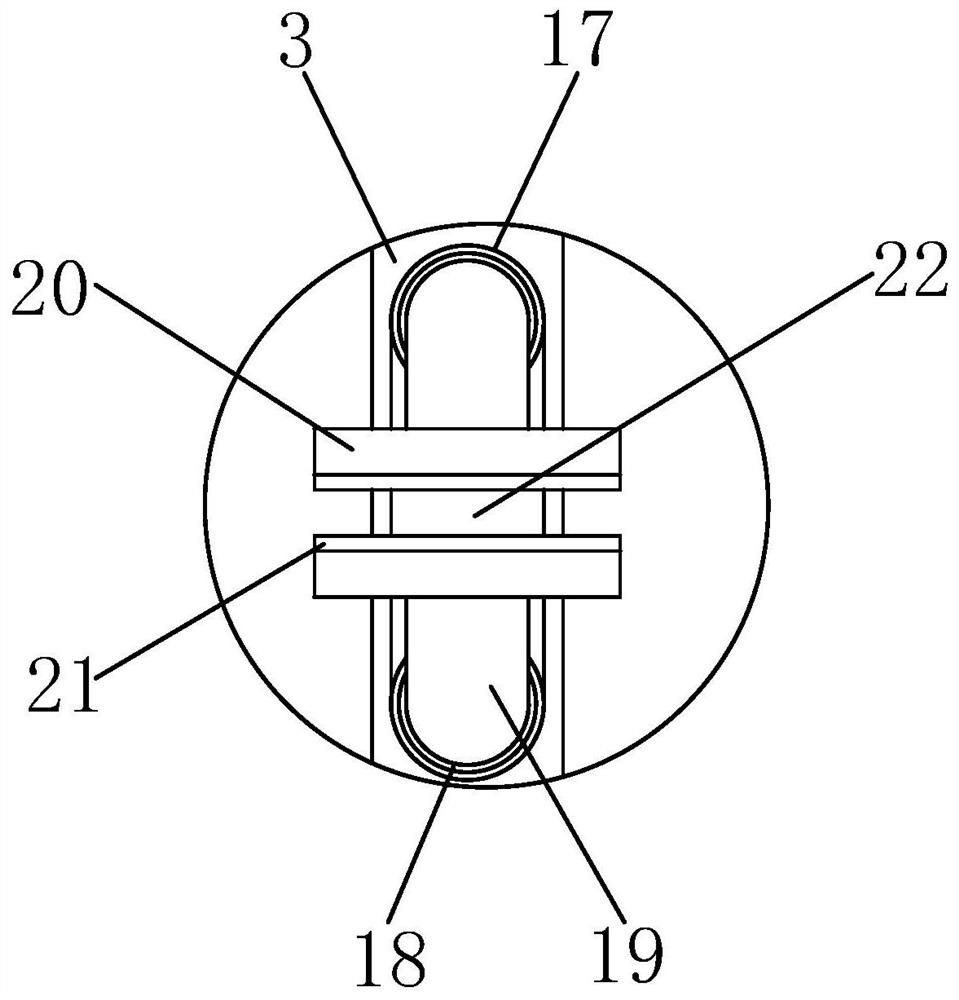

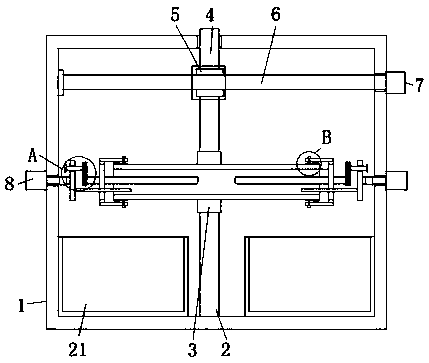

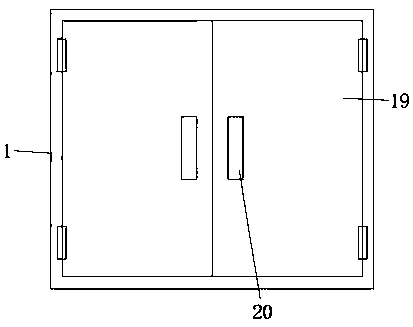

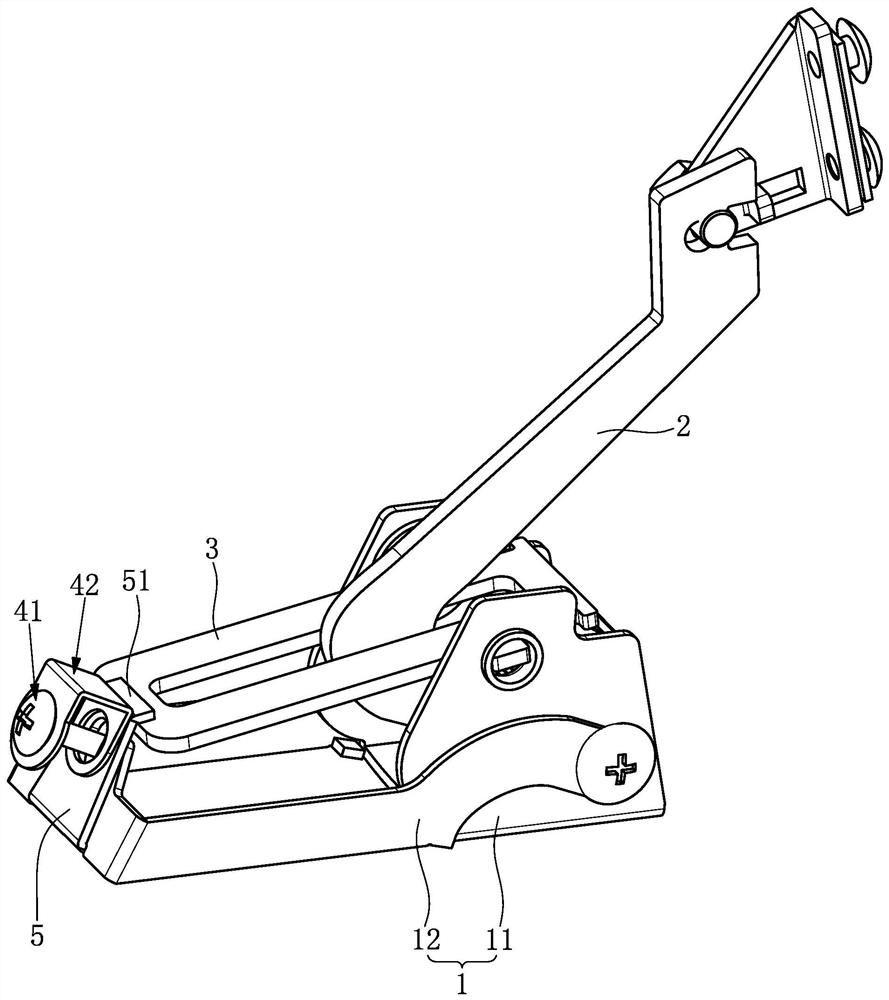

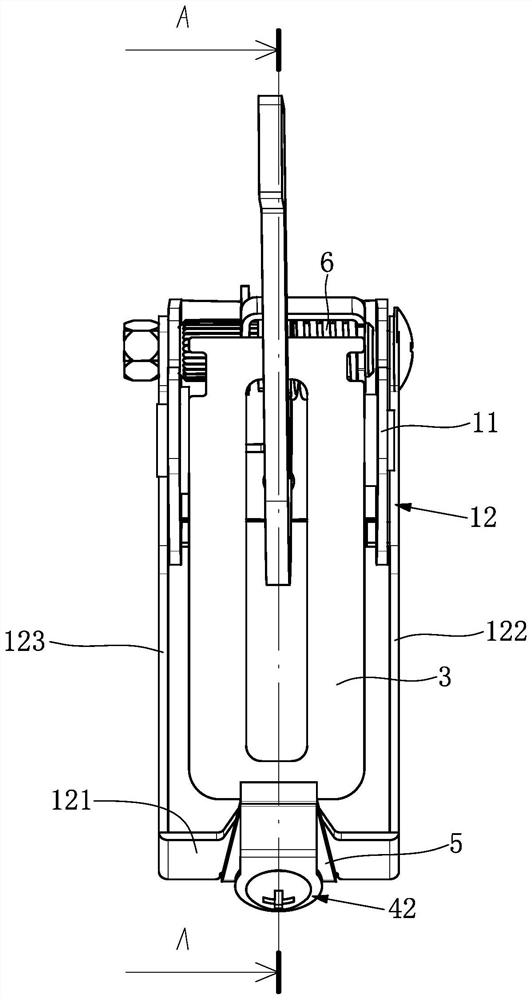

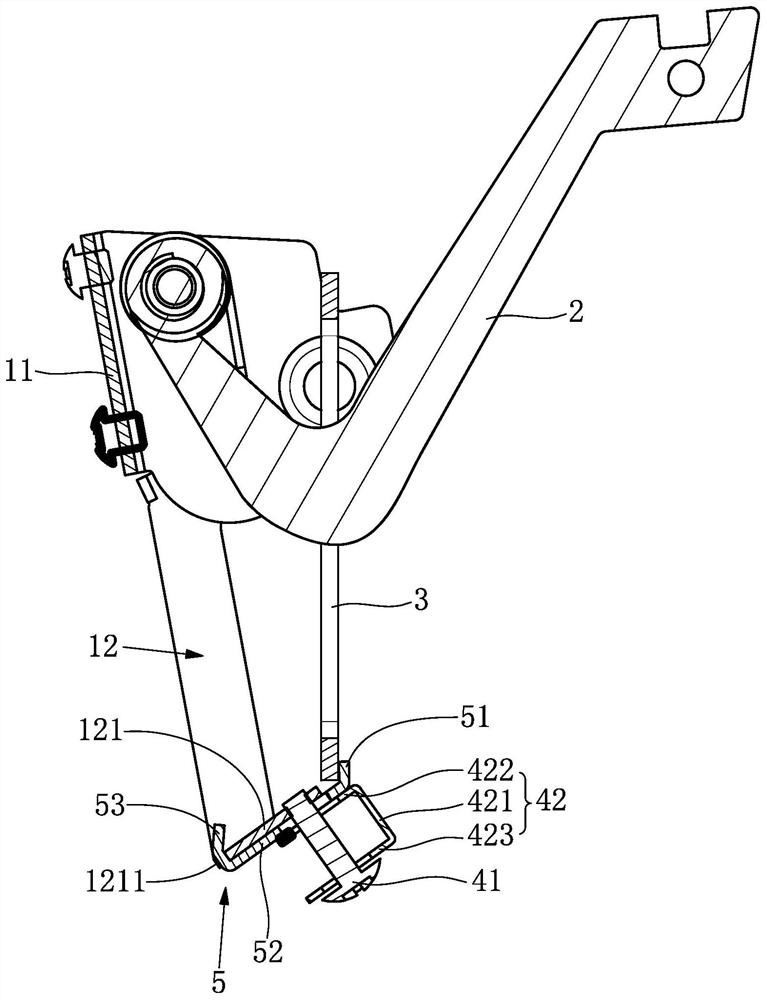

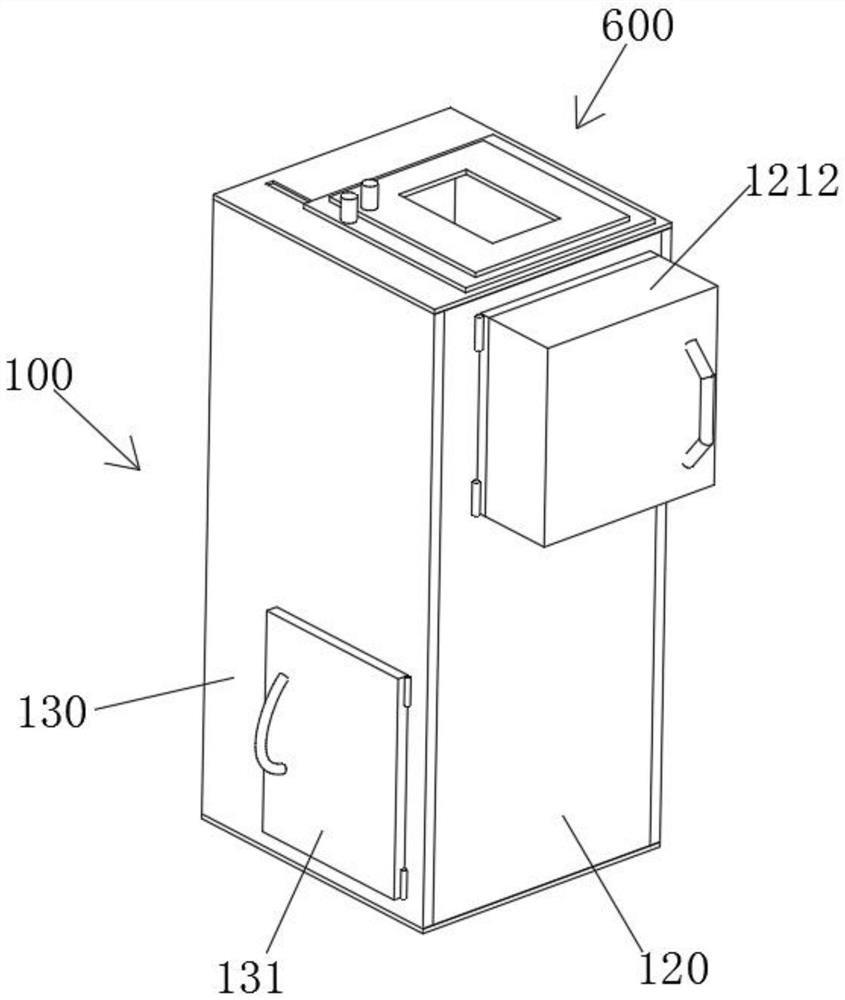

Clamp holder for flat panel display

InactiveCN109630815AStable clamping deviceEasy to change the distanceStands/trestlesFlat panelMechanical engineering

The invention discloses a clamp holder of a flat panel display. The clamp holder comprises a clamping device, wherein the clamping device comprises a clamping plate, the clamping plate comprises a clamping connecting plate and a sliding connecting plate, the clamping connecting plate is in sliding connection with the sliding connecting plate, return springs are correspondingly connected to the end, facing the sliding connecting plate, of the clamping connecting plate and the end, facing the clamping connecting plate, of the sliding connecting plate, and a plurality of clamping buckles are arranged on the top surfaces of the clamping connecting plate and the sliding connecting plate; and the clamping buckles are all arranged towards joints of the clamping connecting plate and the sliding connecting plate, and telescopic devices are arranged between the clamping buckles, the clamping connecting plate and the sliding connecting plate. The clamp holder of the flat panel display can conveniently change the distance between the clamping connecting plate and the sliding connecting plate and is suitable for the width of the flat panel display; and the arrangement of the telescopic devicesis used for changing the distance between the clamping buckles, the clamping connecting plate and the sliding connecting plate, so that the flat panel display with various thicknesses is suitable.

Owner:HEFEI MINZHONGYIXING SOFTWARE DEV CO LTD

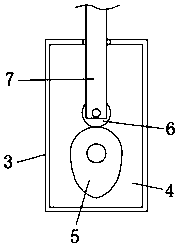

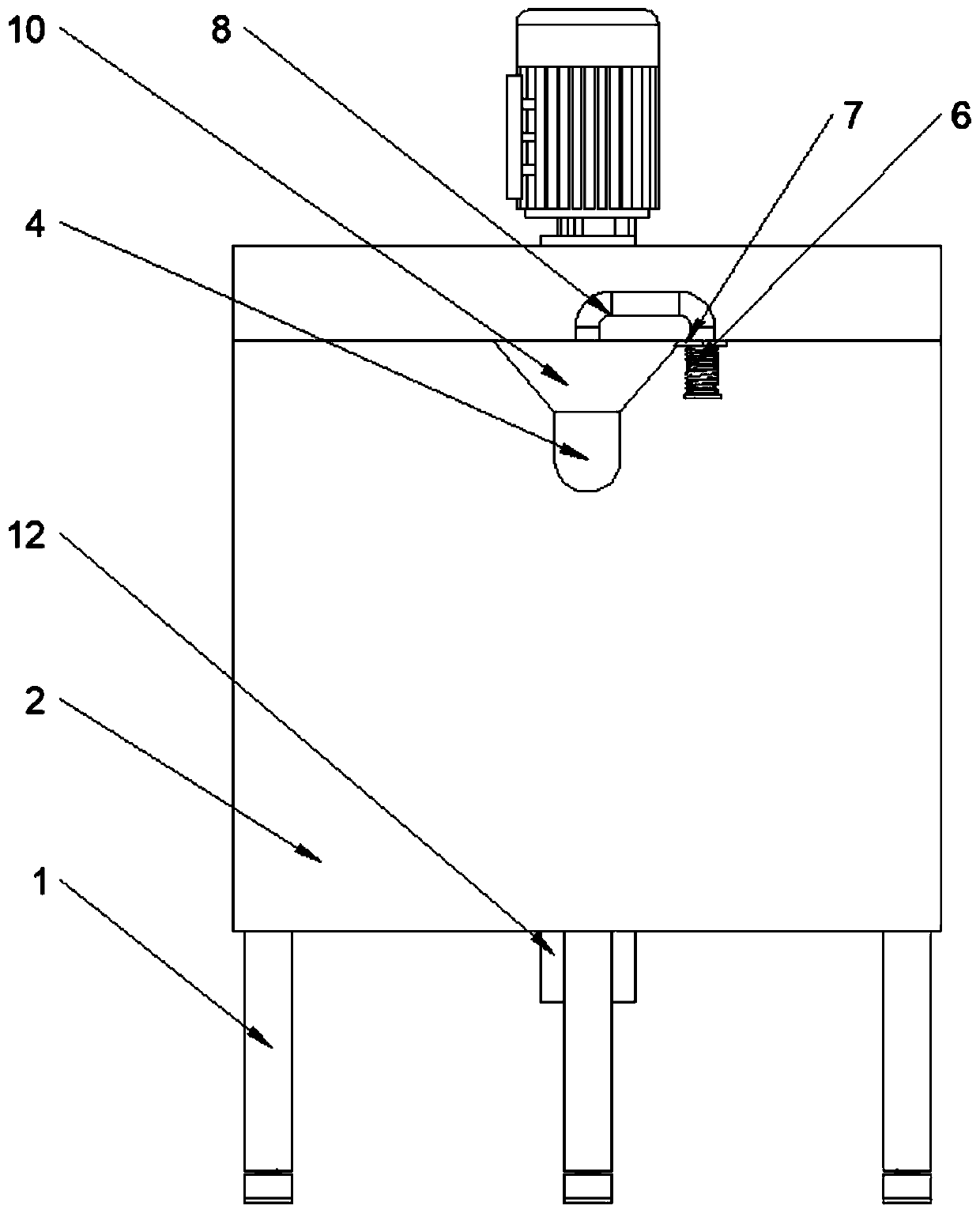

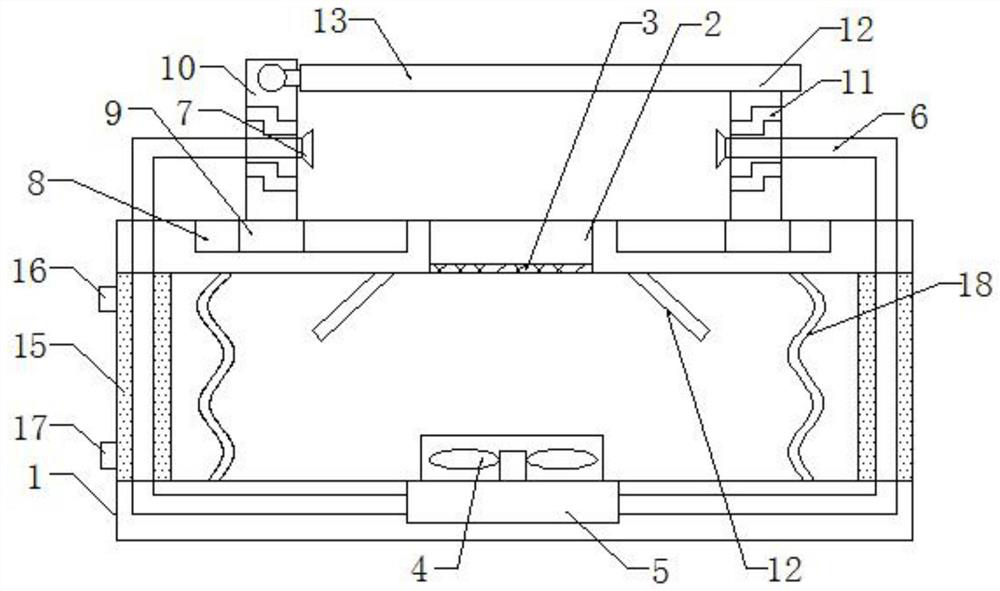

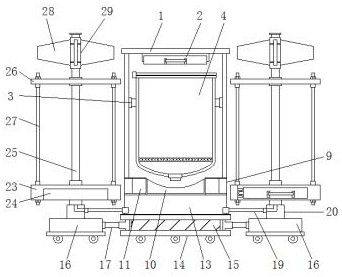

Spraying washing device for semi-automatic pulsator washing machine

InactiveCN109137362AEasy to change heightImprove spraying effectOther washing machinesWashing machine with receptaclesEngineeringCam

The invention discloses a spraying washing device for a semi-automatic pulsator washing machine. The spraying washing device comprises an outer cylinder. An inner cylinder is installed on the inner bottom wall of the outer cylinder in a rotating manner; a fixation plate is installed at the lower side of the inner wall of the inner cylinder by a locking bolt; a mounting slot is formed in the top ofthe fixation plate; a cam is arranged in the mounting slot; a guide pulley is arranged at the top of the cam movably; a movable rod is fixedly installed at the top of the guide pulley; and the upperend of the movable rod extends out of the mounting slot and is welded with a mounting plate. A water collection box is fixedly installed at the bottom of the mounting plate; and a plurality of nozzlesare fixedly connected to the bottom of the water collection box. An opening is formed in the center of the mounting plate; a water inlet pipe is fixedly installed on the inner wall of the opening; and the lower end of the water inlet pipe extends to the inside of the water collection box and the upper end of the water inlet pipe extends out of the outer cylinder. The spraying washing device basedon the reasonable structure is convenient to use; the distance between the nozzle and the clothes can be changed conveniently; the spraying effect is improved. And the spraying washing device is suitable for promotion.

Owner:ANHUI JINSHUAI WASHING MACHINE

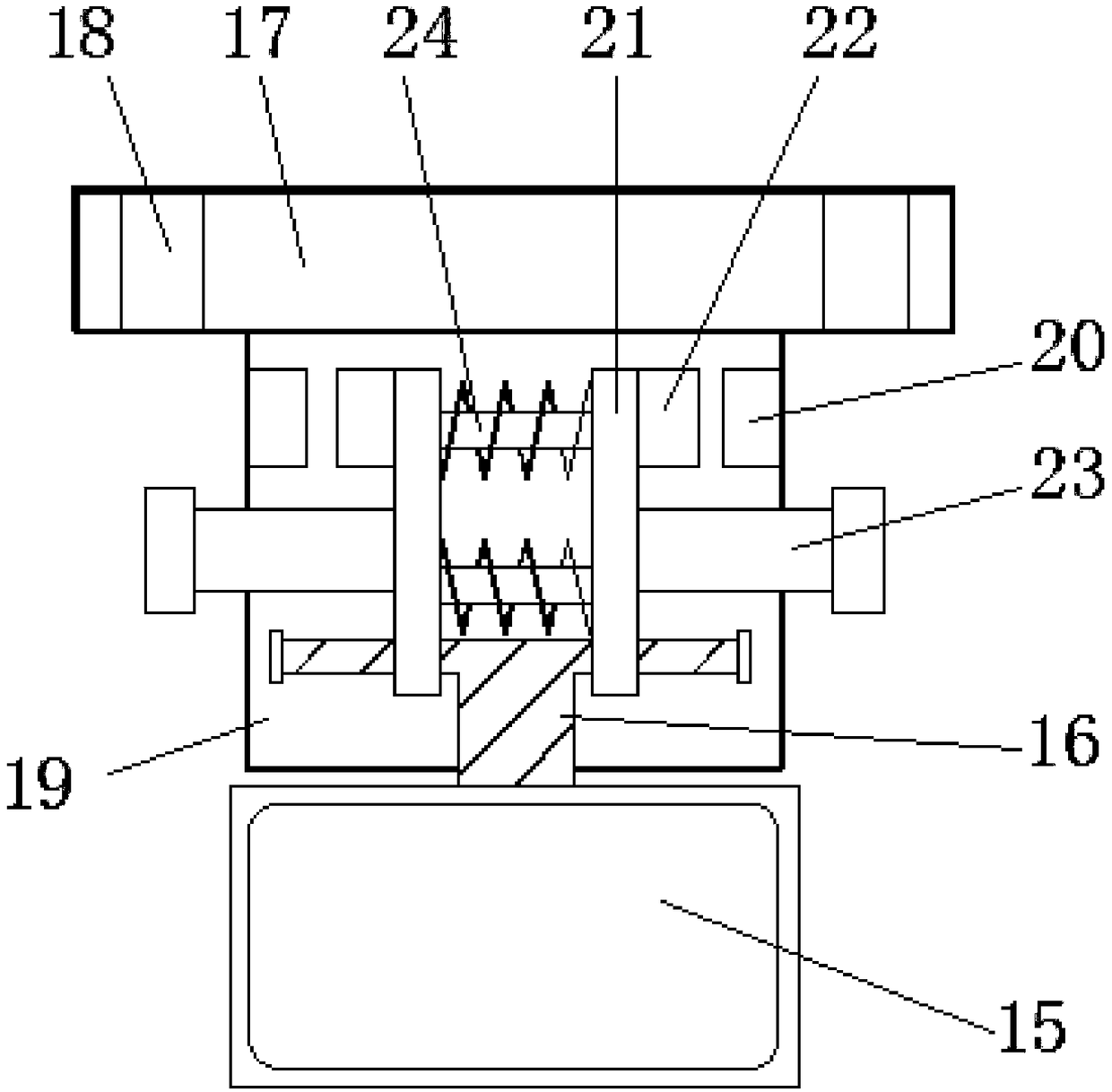

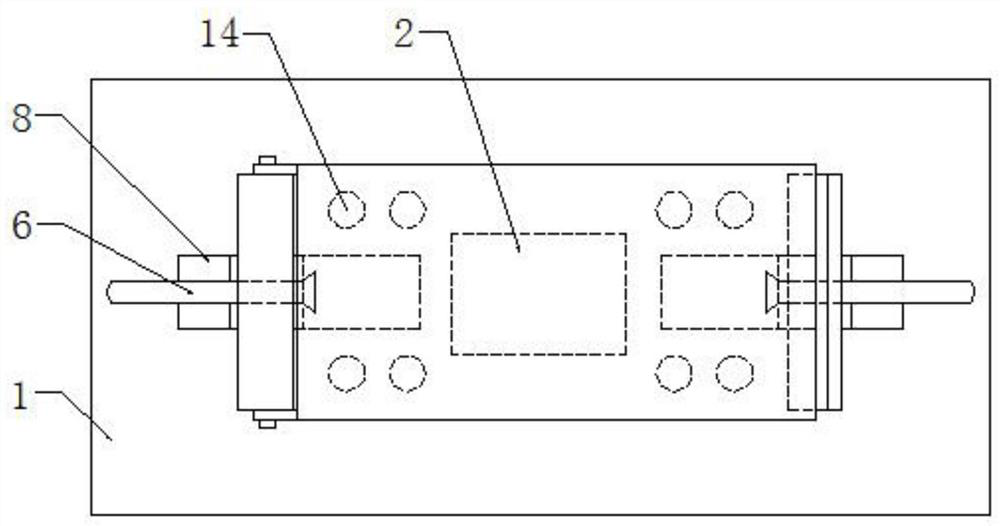

Semiconductor resistance detection system and detection method thereof

ActiveCN112730989AQuick checkImprove work efficiencyResistance/reactance/impedenceMeasurement instrument housingHemt circuitsEngineering

The invention discloses a semiconductor resistor detection system and a detection method thereof. The system comprises a bottom plate, stand columns are fixedly arranged on the two sides of the upper end of the bottom plate, fixed rings are fixedly arranged at the upper ends of the stand columns, first sliding grooves are formed in the outer side surfaces of the upper ends of the fixed rings, and first sliding blocks are movably arranged in the first sliding grooves; an adjusting mechanism is arranged at the upper end of the first sliding block, the adjusting mechanism comprises a rotating ring, a first mounting base, a cross rod, a first motor, a first bevel gear, a first sliding rod, a first screw rod and a second bevel gear, and the rotating ring is fixedly arranged at the upper end of the first sliding block. The device is good in use effect, the detection head can automatically adjust the position according to the detected height difference of the surface circuit of the component so as to facilitate detection work, meanwhile, the position of the detection head can be adjusted in a multi-angle and multi-range mode, and therefore, the device can adapt to detection of various different components.

Owner:STATE GRID ZHEJIANG NINGBO YINZHOU POWER SUPPLY LTD CO +1

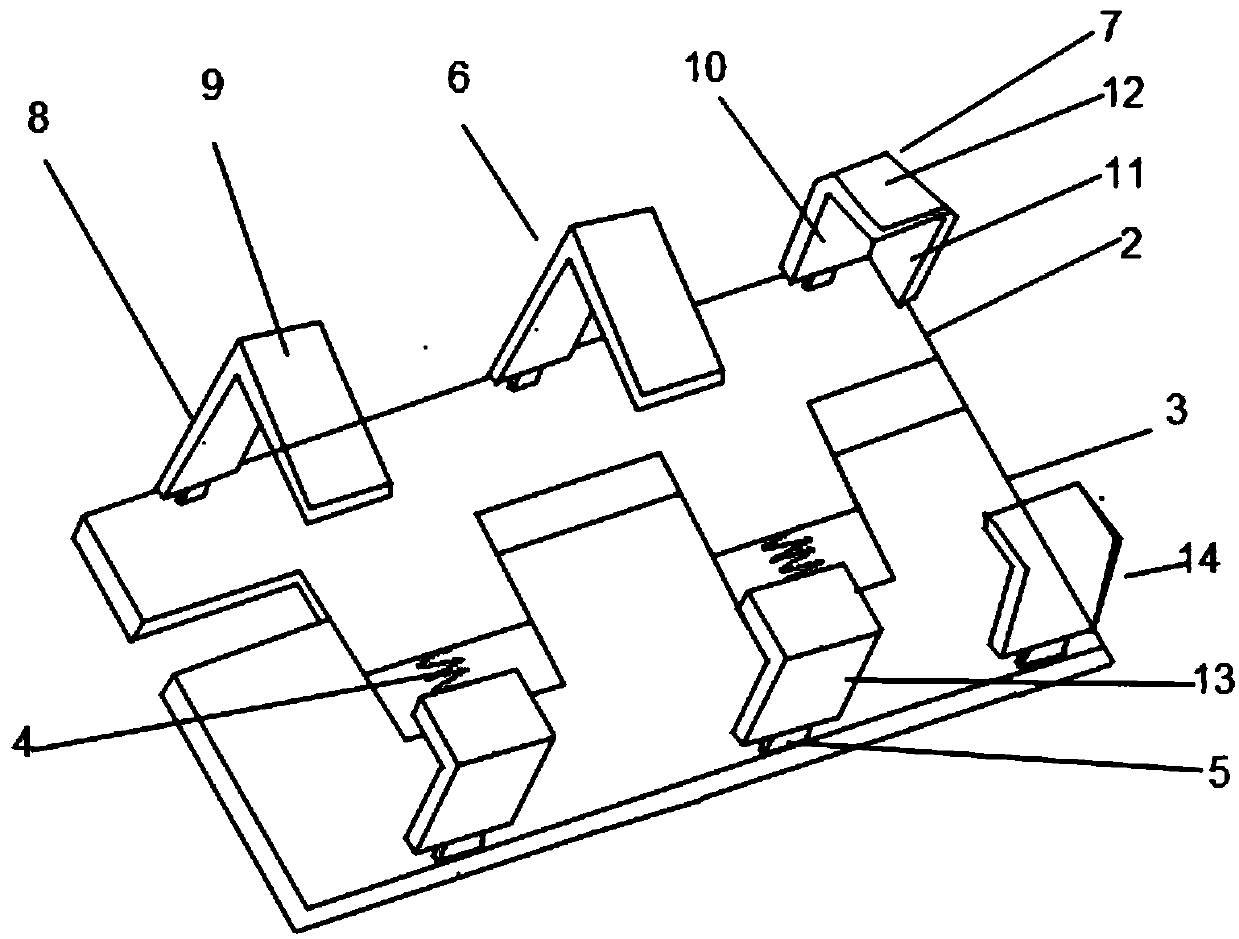

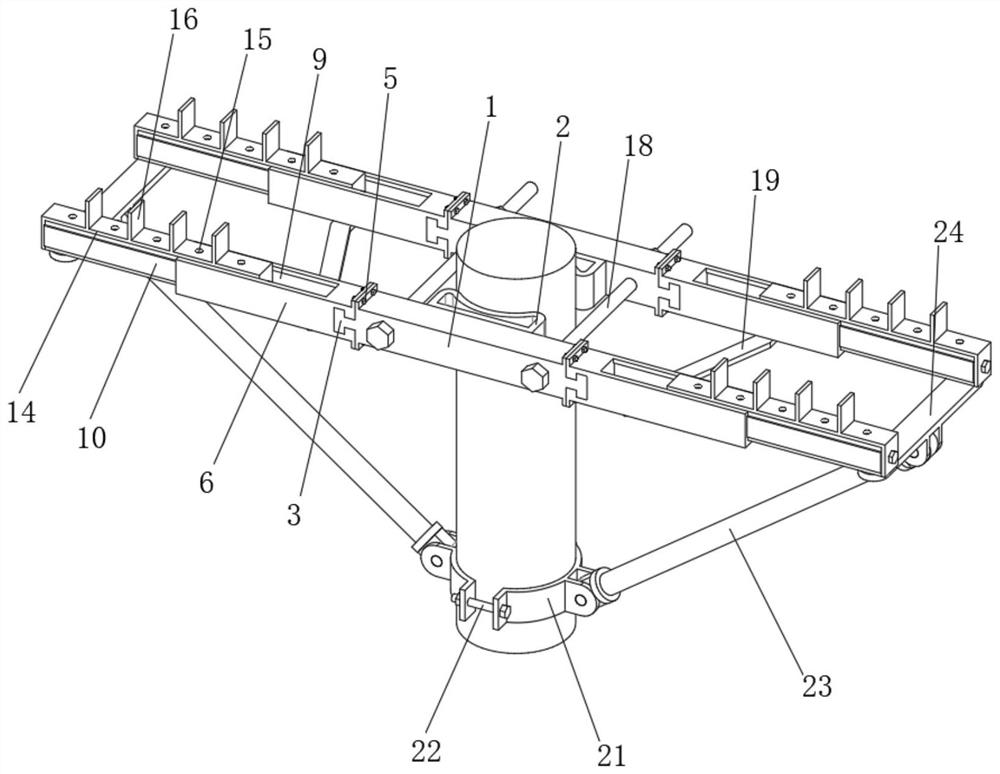

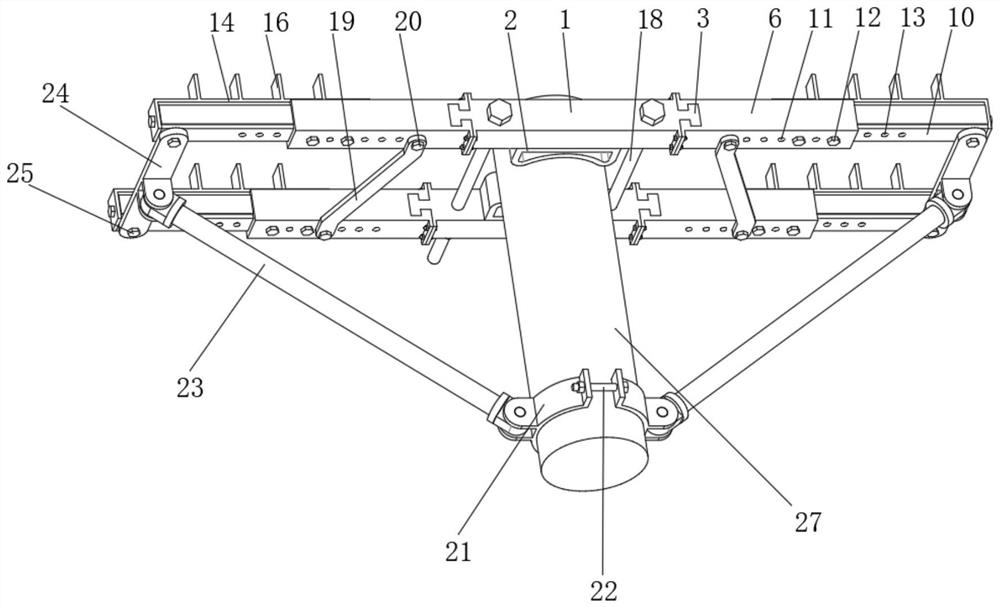

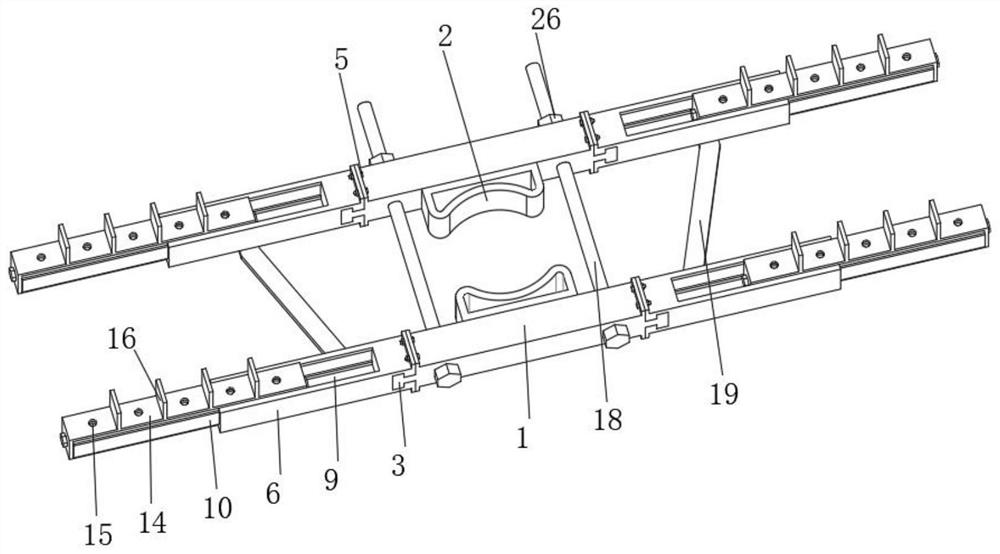

Assembled cross arm structure applied to electric tower

The invention discloses an assembled cross arm structure applied to an electric tower, and relates to the technical field of electric iron components, in particular to the assembled cross arm structure applied to the electric tower, which comprises a first cross arm assembly and the electric tower, and the left end and the right end of the first cross arm assembly are fixedly connected with connecting tenons; first connecting edges are fixedly connected to the upper and lower surfaces of the left and right ends of the first cross arm assembly, second cross arm assemblies are connected to the left and right ends of the first cross arm assembly, and connecting mortises are formed in the ends, close to the first cross arm assembly, of the second cross arm assemblies. According to the assembled cross arm structure applied to the electric tower, the cross arm is designed to be of an assembled structure, components of the cross arm can be transported to a high position firstly, then the components of the cross arm are assembled, the size of the cross arm in the carrying process is reduced, the carrying difficulty is lowered, meanwhile, a double-cross-arm structure is adopted, the wind resistance of the cross arm under the condition of strong wind is improved, and the service life of the cross arm is prolonged. And the cross arm is prevented from being damaged by strong wind.

Owner:东台市新杰科机械有限公司

A hydraulic trailer device

InactiveCN109094447AEasy to fixAvoid shakingItem transportation vehiclesHydraulic cylinderArchitectural engineering

A hydraulic trailer apparatus including the front, Cars and wheels, one side of the vehicle head is provided with a vehicle compartment, Wheels are fixedly mounted at the four corners of the bottom ofthe car, the middle position of the car is provided with a mounting cavity, a hydraulic cylinder is welded in the middle position of the inner bottom wall of the mounting chamber, A horizontal plateis fixedly mounted on the piston rod of the hydraulic cylinder, the middle position of the transverse plate is provided with a groove, two-way threaded columns are rotatably installed on both sides ofthe inner wall of the groove, the two sides of the two-way threaded column are all threaded with movable plates, A support rod is fixedly connected with the top of the movable plate, a fixing block is welded on the top of the support rod, two ends of two bidirectional threaded columns close to each other are fixedly connected with mounting columns, a driving motor is fixed at the middle positionof the top of the transverse plate through locking bolts, and an output shaft of the driving motor extends to the inside of the groove. The invention has the advantages of simple structure, reasonabledesign and novel conception, improves the stability of the trailer equipment when in use, and is suitable for popularization.

Owner:滁州安阳智能科技有限公司

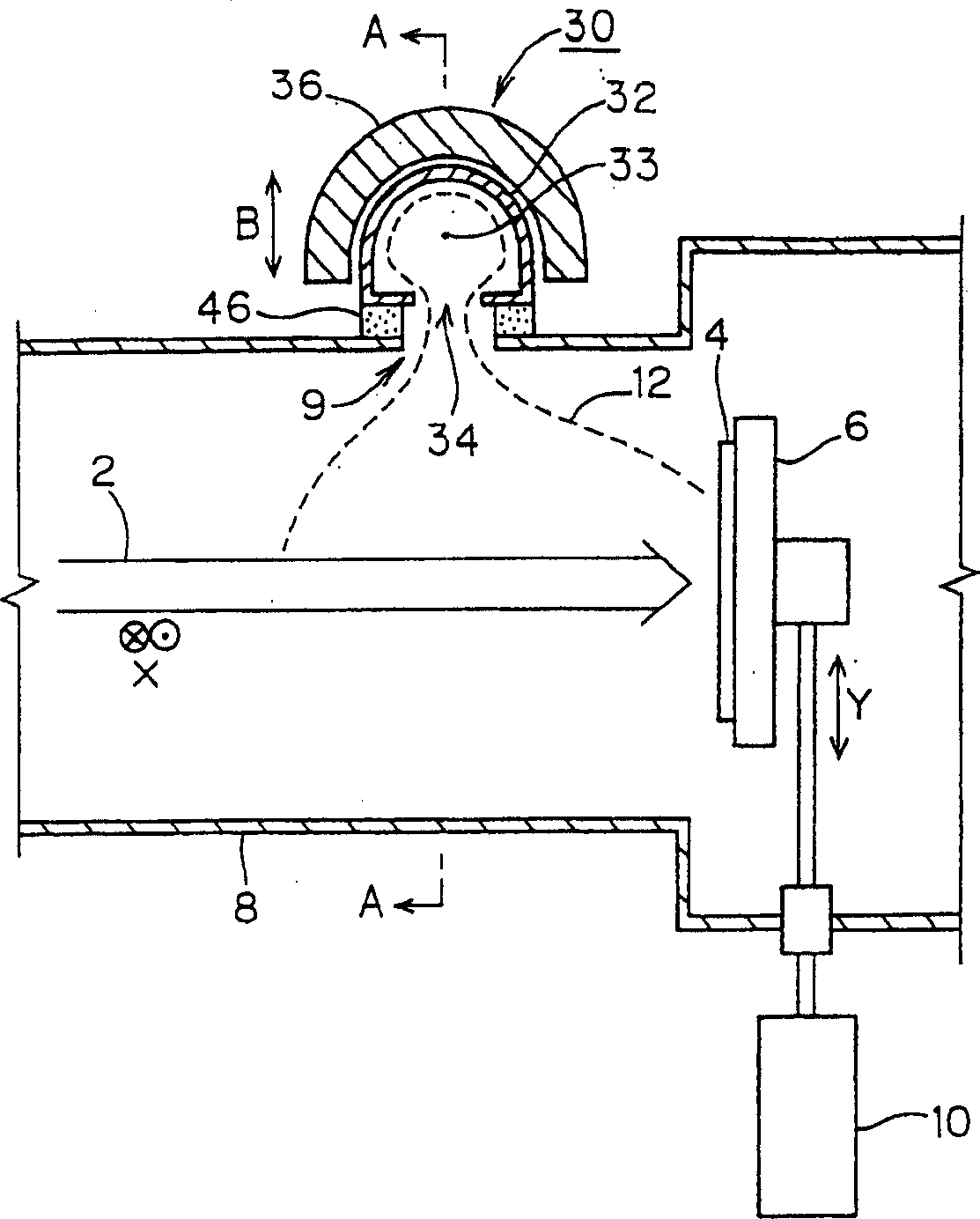

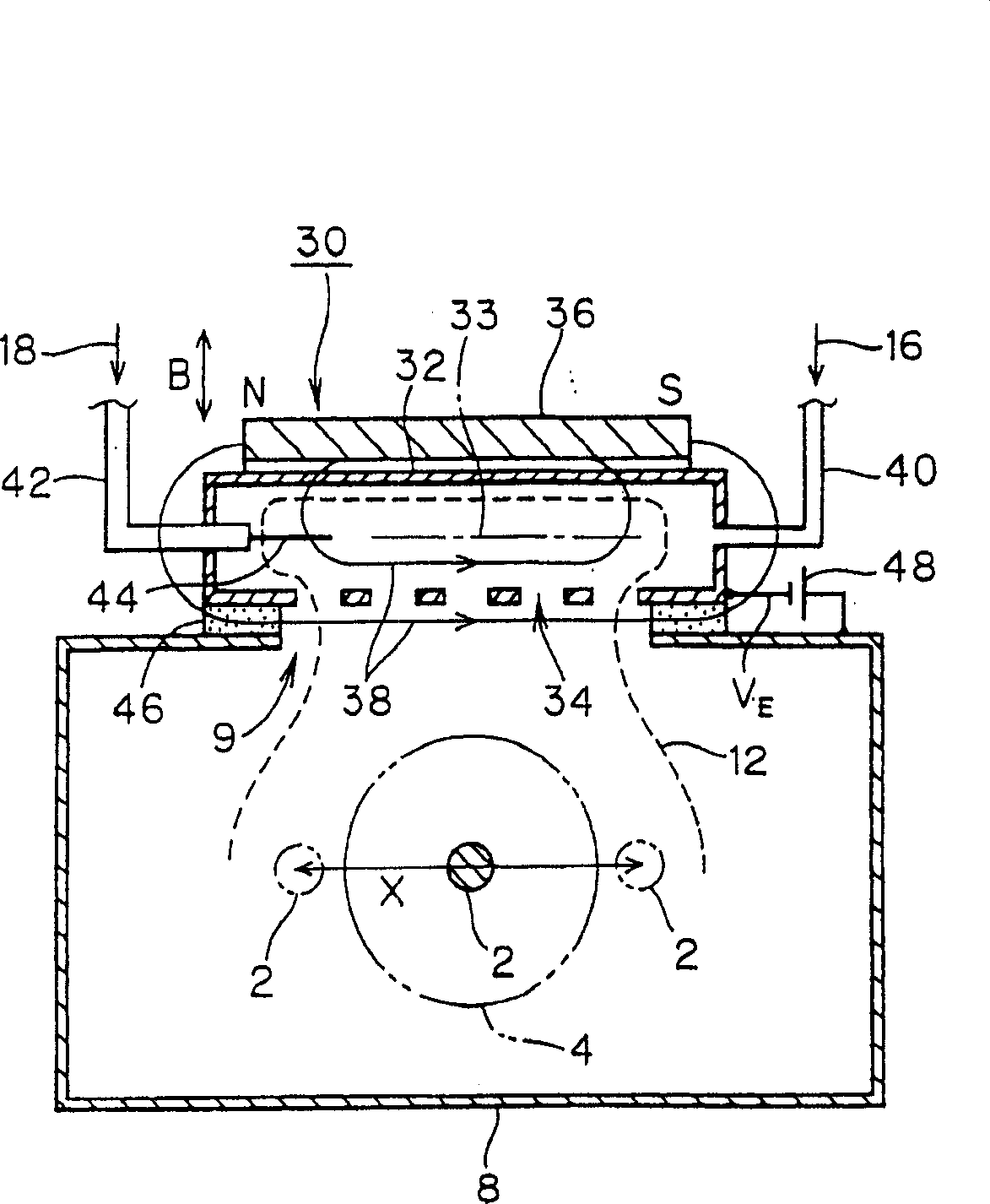

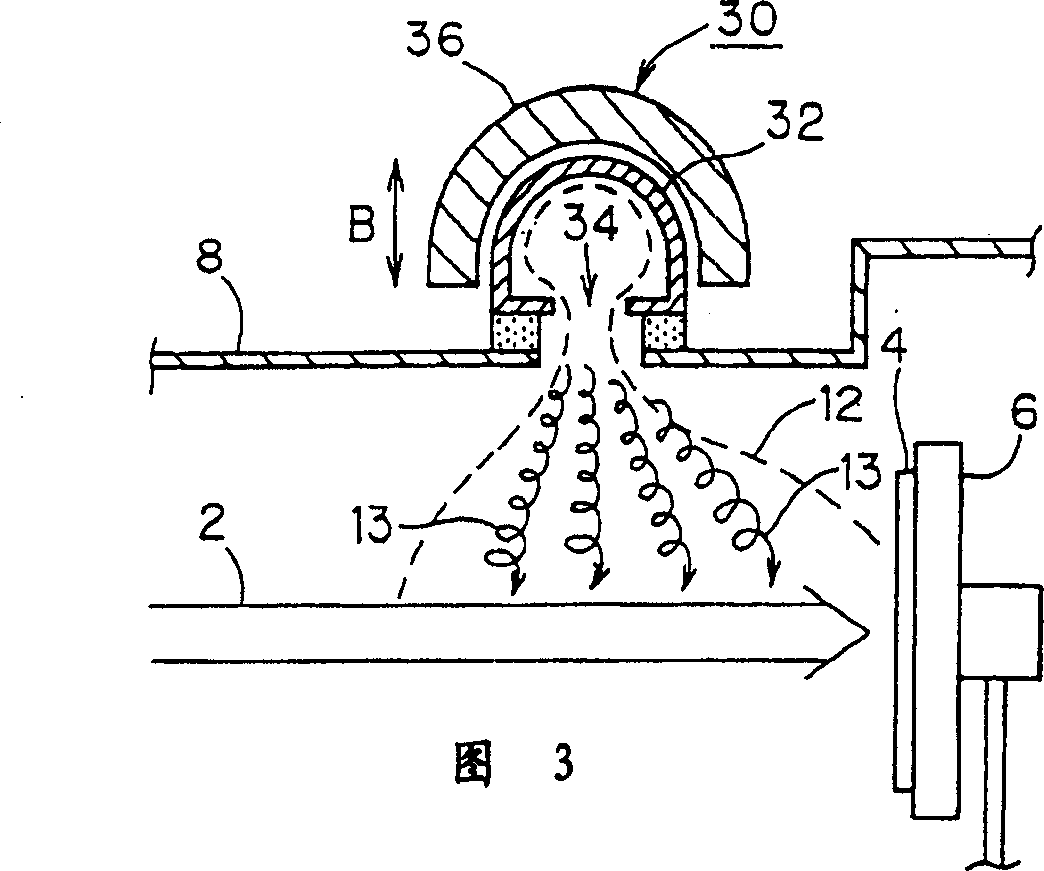

Ion generator for ion beam radiator

InactiveCN1356860AImprove balanceEasy to change the distanceVacuum evaporation coatingSemiconductor/solid-state device manufacturingRadio frequencyMagnet

An ion beam irradiation apparatus is provided with a plasma production device 30 which produces a plasma 12 through the radio frequency discharge and supplies the produced plasma in the vicinity of the substrate 4. The plasma production device 30 includes a plasma producing chamber 32 being elongated along an axis 33 extending in scanning directions X in which the ion beam is moved; a plasma emission hole 34 being provided in a side thereof and elongated along the axis 33 of the plasma producing chamber; and a magnet 36 provided outside the plasma producing chamber 32 for producing a magnetic field having a direction along the axis 33. The magnetic field developed by the magnet 36 contains a magnetic field which has a direction along the axis and bends to the substrate ions contained in the plasma 12 emitted from a plasma emission hole 34.

Owner:日新意旺机械股份会社

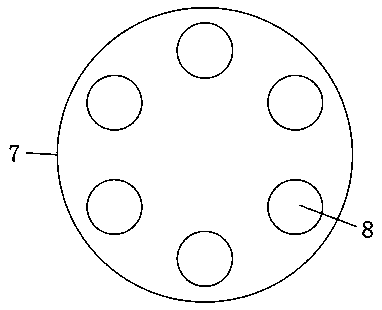

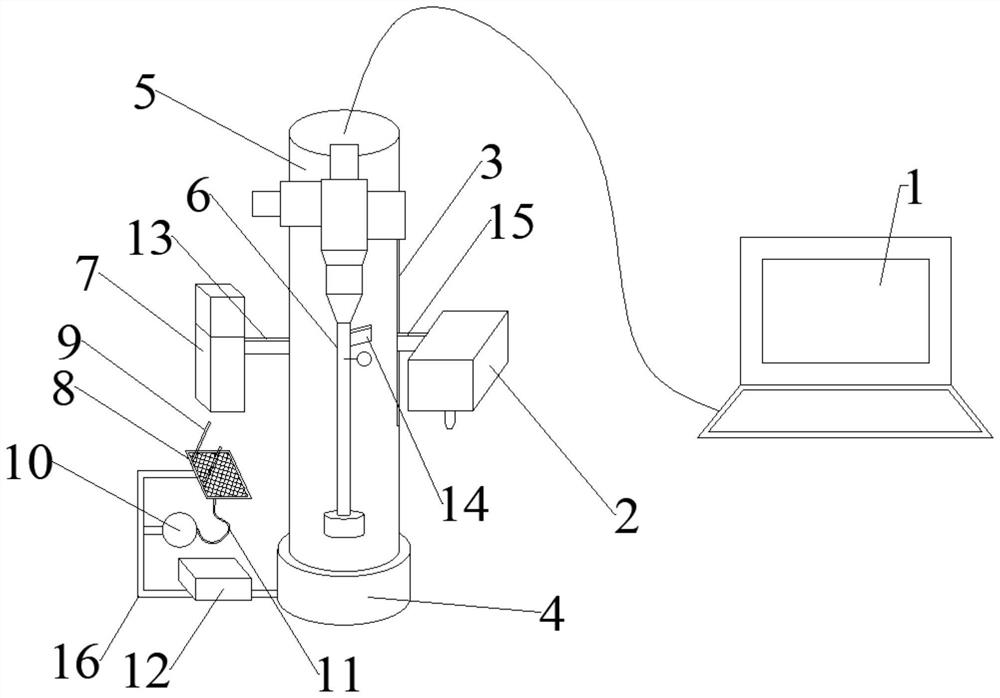

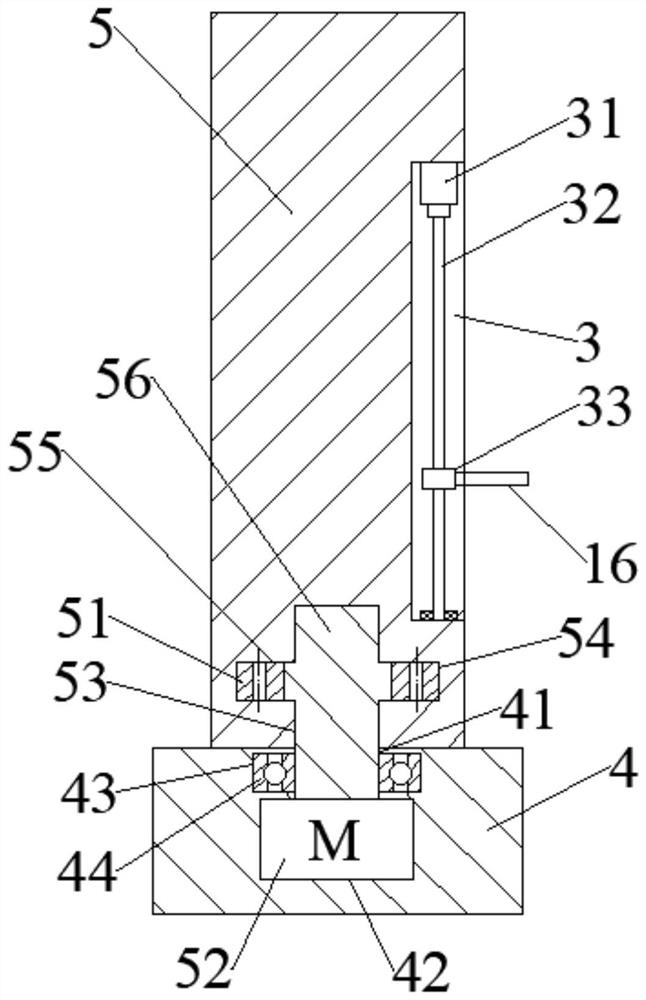

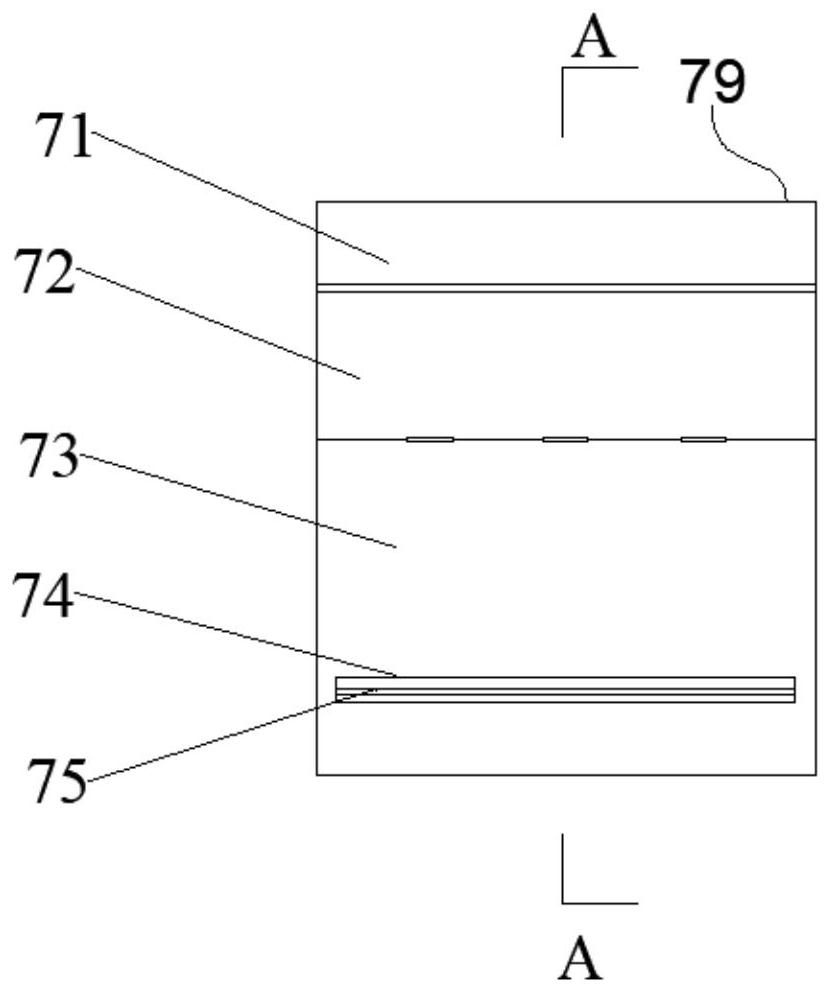

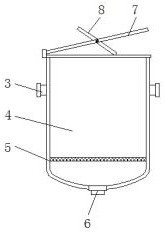

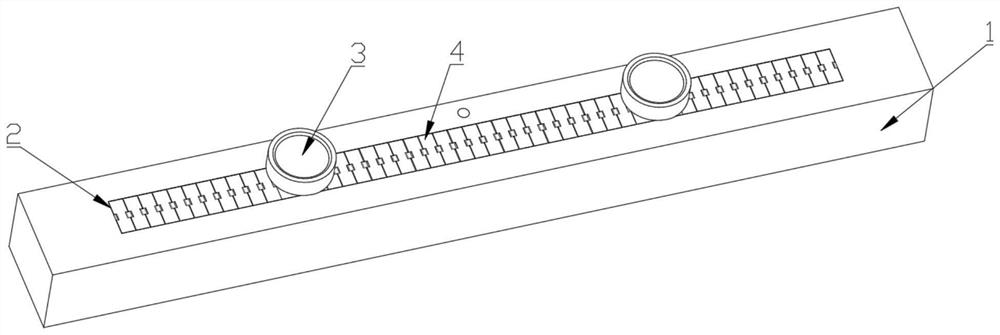

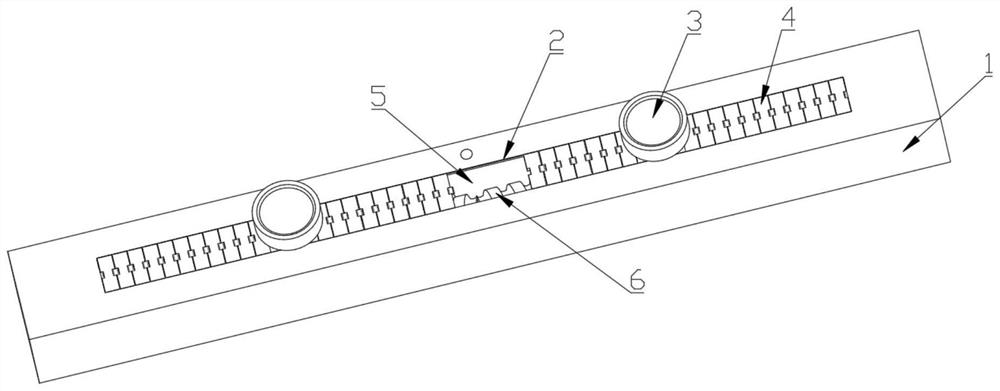

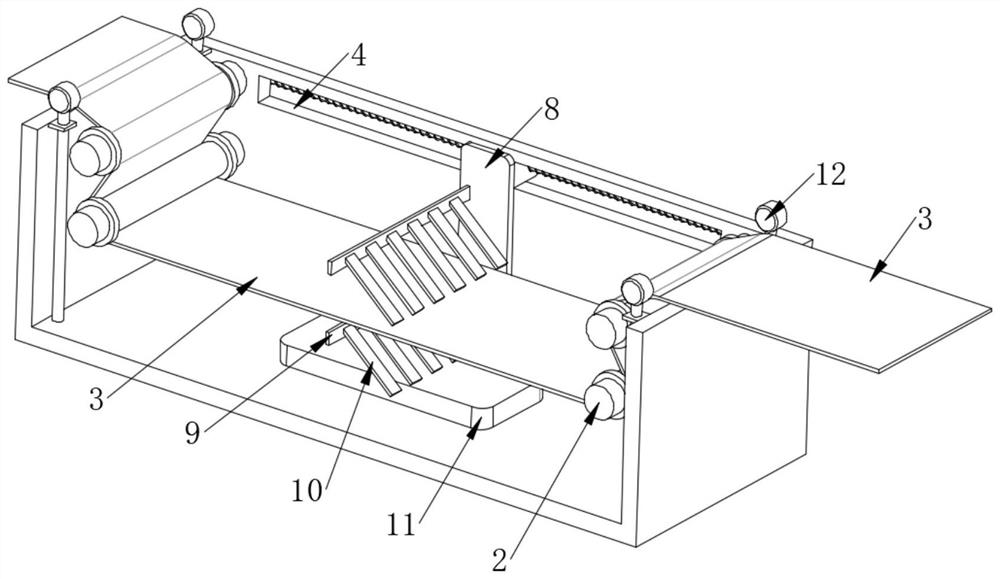

On-line continuous detection device for free silica dust concentration based on Raman spectroscopy

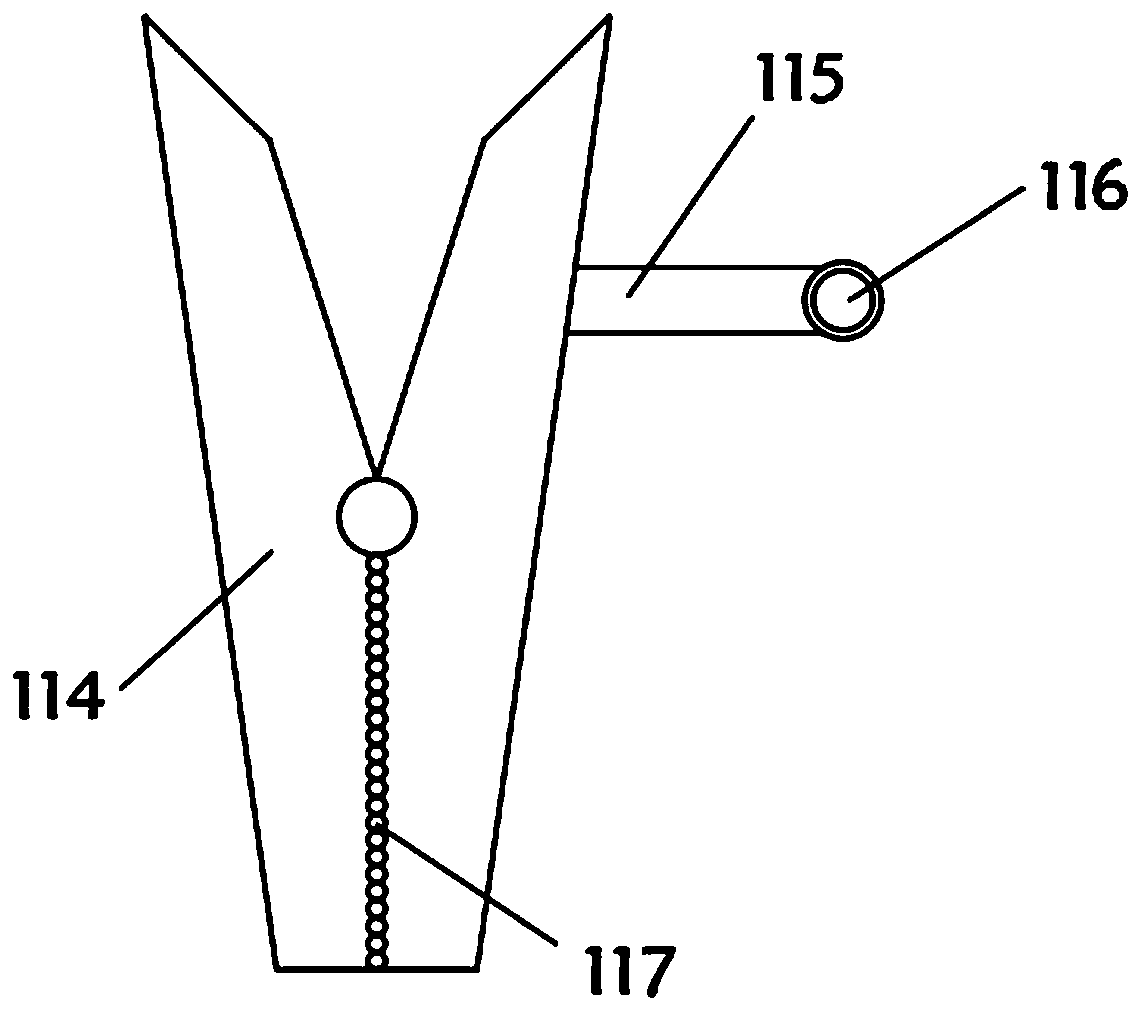

ActiveCN113358535BEasy accessEasy to cutRaman scatteringParticle suspension analysisOptical spectrometerCollection system

An on-line continuous detection device for free silica dust concentration based on Raman spectroscopy, the base rotates with the rotating cylinder; the filter paper taking system includes a paper picker; the paper picker is connected to the left side of the rotating cylinder; the filter plate passes through Supported by a vertical support frame, the filter paper clip is installed on the filter plate; one end of the hose is connected to the air pump, and the other end is set under the filter plate; the filter paper recovery box is located under the filter plate; the free silica dust collection system is connected On the front side of the rotating cylinder, it consists of a cyclone-type particle size cutting head, a sampling head, an airflow pipeline, a shrinking nozzle and an isolation cover, and the flowmeter is connected to the airflow pipeline; the Raman spectroscopy system includes a The vertical chute on the side, the screw motor at the top, the screw at the bottom, the slider set outside the screw and the Raman spectrometer on the right side of the rotating cylinder; the Raman spectrometer is connected to the Slider connection. The device has a simple structure and can continuously and conveniently perform detection operations.

Owner:CHINA UNIV OF MINING & TECH

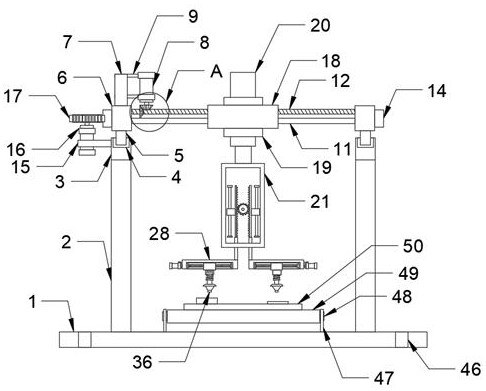

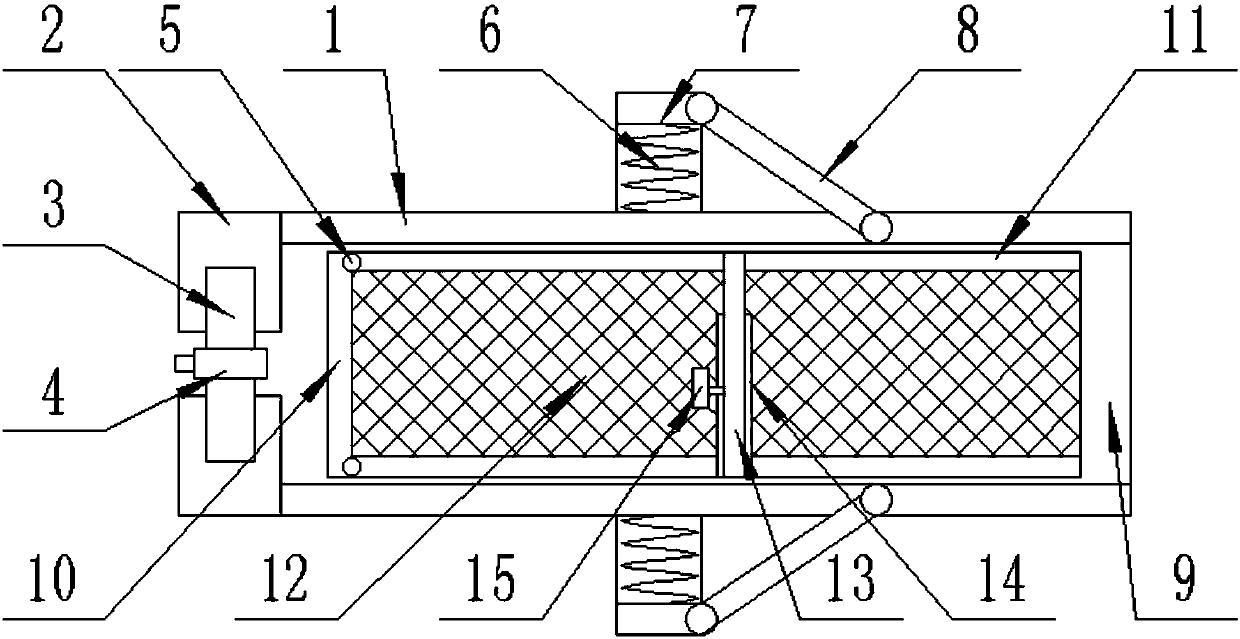

Tensile strength testing equipment used in production process

InactiveCN112985985AGuaranteed to be verticalEasy to stretchMaterial strength using tensile/compressive forcesHydraulic cylinderTensile testing

The invention discloses tensile strength testing equipment used in a production process. The tensile strength testing equipment comprises strength tensile testing equipment, wherein the strength tensile testing equipment comprises a tensile testing base, the front surface of the tensile testing base is fixedly connected with a fixing frame, the front surface of the tensile testing base is provided with moving grooves, and the number of the moving grooves is two. According to the invention, clamping plates are driven by a hydraulic cylinder to move, the two clamping plates clamp an object, the stability of the fixed end of the object is ensured, the object is inconvenient to move, a movable frame is conveniently controlled to move in the forward direction, the object is stretched, the fixing effect is improved, stretching operation is facilitated, the advantage of convenient clamping and fixing is achieved, andthen the problems that existing strength stretching equipment is poor in fixing effect, an object cannot be well fixed, the object is prone to moving in the stretching process, and the strength stretching process of the object is affected are effectively solved.

Owner:上海奉斌贸易有限公司

Sewer filtering device for building construction

InactiveCN107700641APrevent pollution and rustPrevent disengagementFatty/oily/floating substances removal devicesSewerage structuresRear quarterWater flow

The invention provides a sewer filtering device for building construction, which belongs to the field of building construction. Including the lower side plate; the two lower side plates are vertically fixed symmetrically with two springs; the two springs are fixed vertically symmetrically with two movable blocks; the right side of the movable block is connected obliquely to the inside by a hinge There are two rotating rods and the other end of the rotating rod is connected to the surface of the lower side plate through a hinge; the left end of the lower side plate is horizontally fixed with two movable rods; the surface of the spring of the present invention is wrapped with a sleeve made of rubber to avoid The spring is corroded; when the movable block moves to the middle at the same time, the movable block compresses the spring, and the spring squeezes the movable block outward, so that the movable block can be pressed against the inner wall of the sewer on both sides, so that the whole device is stable on the inner wall of the sewer and prevents the water flow from driving the device to move; When the movable block moves inwardly, the movable block drives the rotating rod to rotate inwardly through the hinge, so as to prevent the movable block from breaking away from the spring; the movable rod is convenient for changing the distance between the two lower side plates.

Owner:陈萍

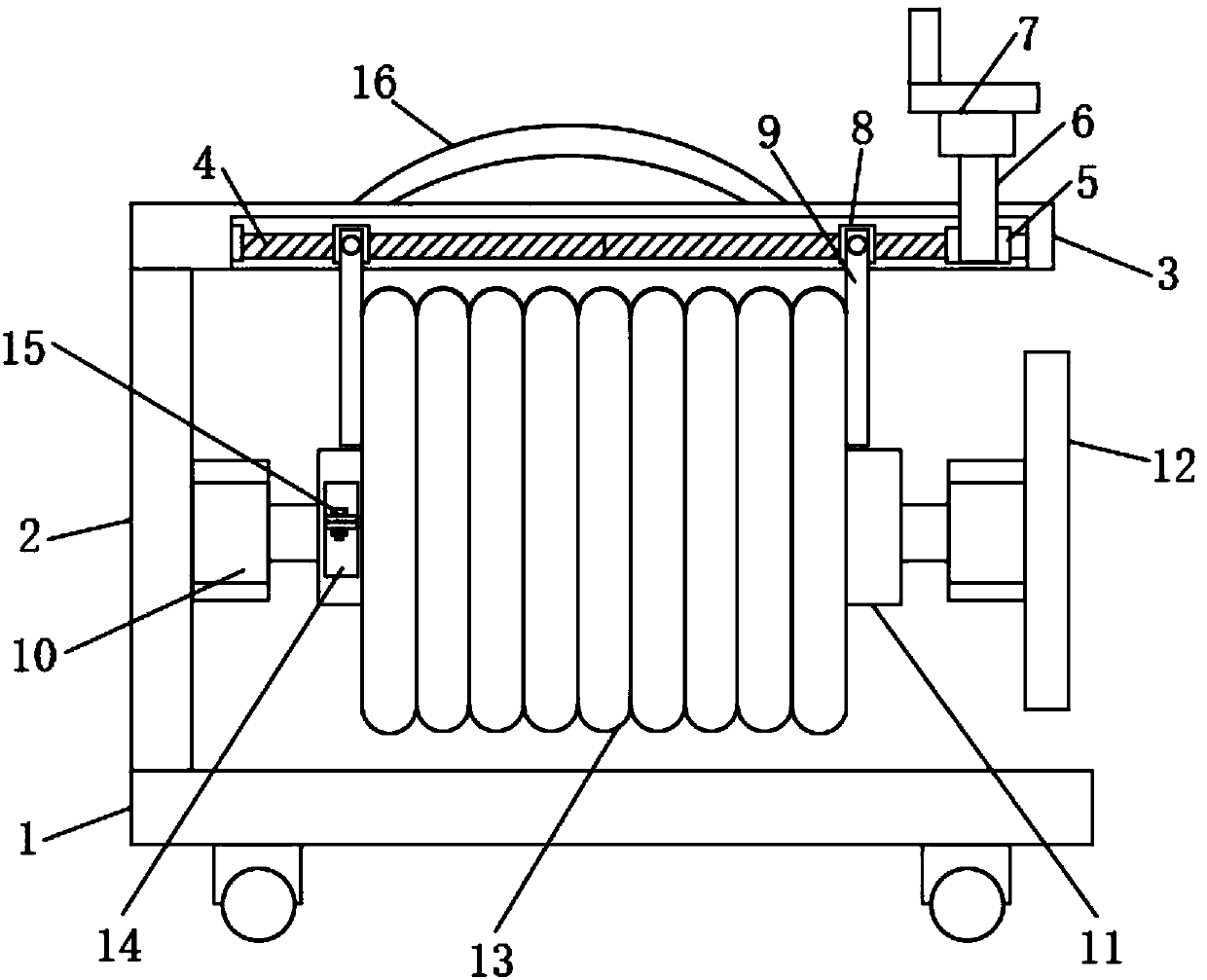

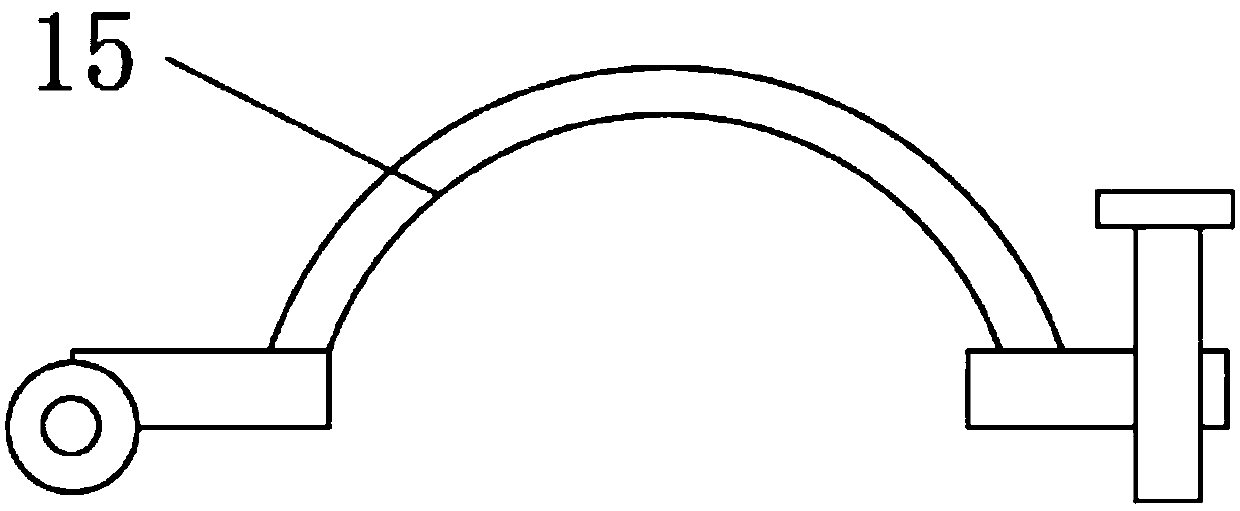

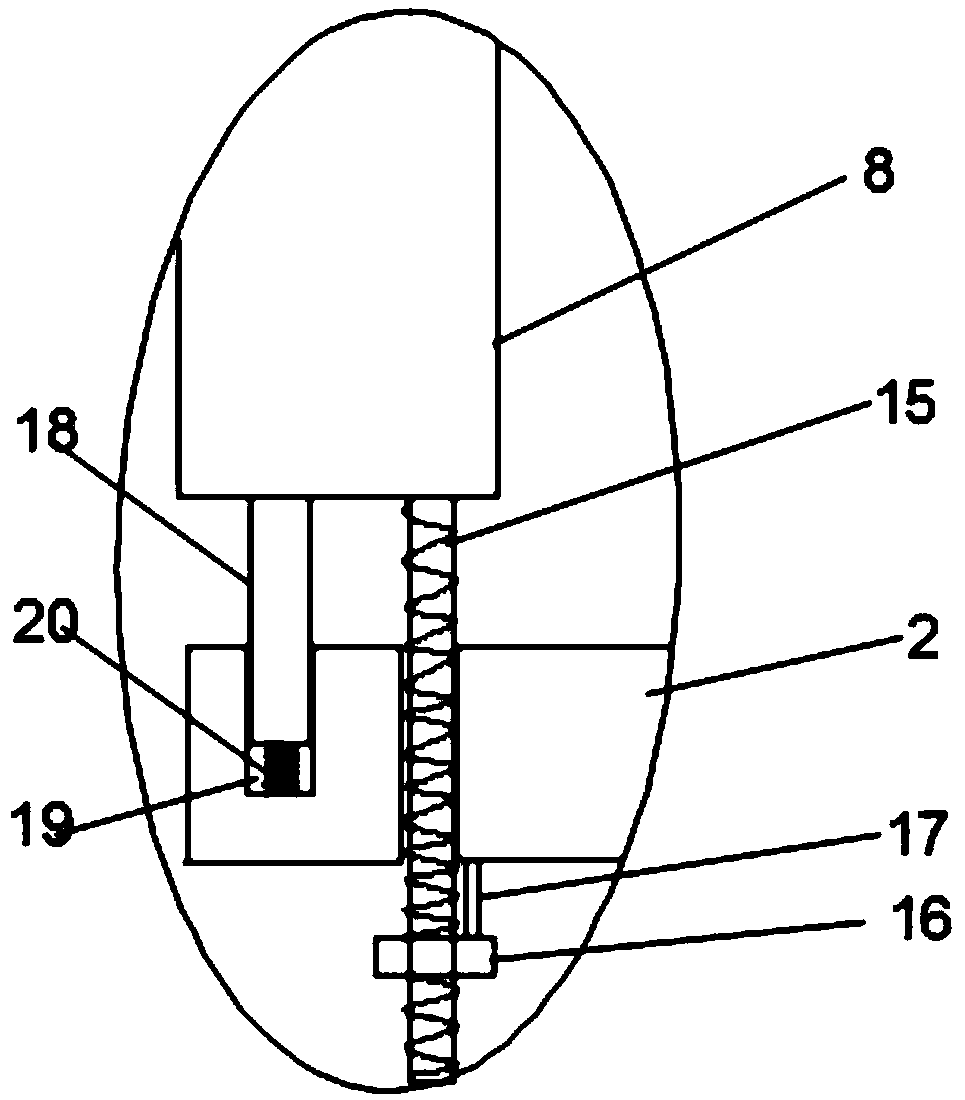

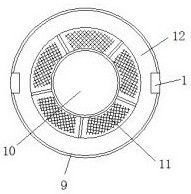

A kind of polishing equipment for the outer wall of the packer rubber cylinder

ActiveCN108908079BEasy to polishImprove polishing effectPolishing machinesSealing/packingPolishingElectric machinery

The invention discloses polishing equipment for a rubber barrel outer wall of a packer. The polishing equipment comprises a polishing equipment main body, wherein a supporting rod is fixed at the middle position of the polishing equipment main body; a first fixed block is mounted at the top of the supporting rod; an opening is formed in the middle position of the top of the polishing equipment main body; a thread sleeve is connected with the inner part of the opening through a thread; the lower end of the thread sleeve extends into the polishing equipment main body; a second fixed block is mounted; a worm wheel sleeves an external thread of the thread sleeve; a worm rod is engaged with the worm wheel; one end of the worm rod extends to the outer part of the polishing equipment main body and is connected with an output shaft of a first driving motor; second driving motors are mounted at middle positions of two sides of the polishing equipment main body through locking bolts; the outputshaft of each second driving motor extends into the polishing equipment main body and is fixedly provided with a rotating plate; each rotating plate is provided with a through hole; a rotating columnis movably arranged in each through hole. The polishing equipment disclosed by the invention is reasonable in structure, ingenious in design, simple to operate, convenient to use and suitable for popularization.

Owner:QINGDAO UNIV OF SCI & TECH

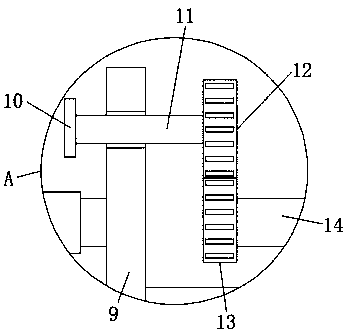

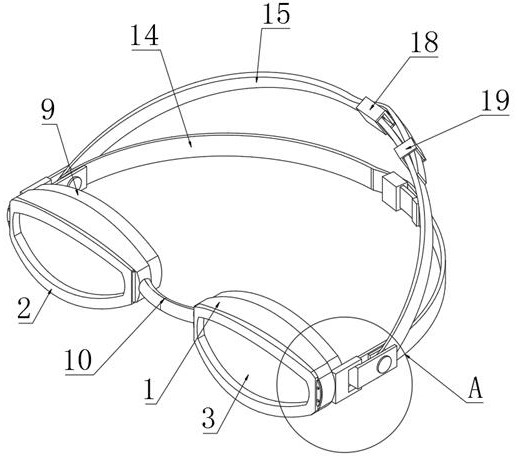

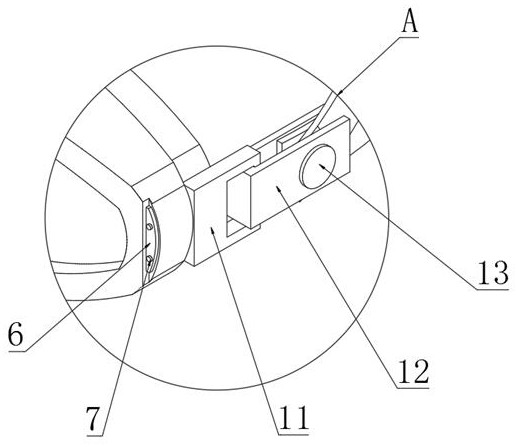

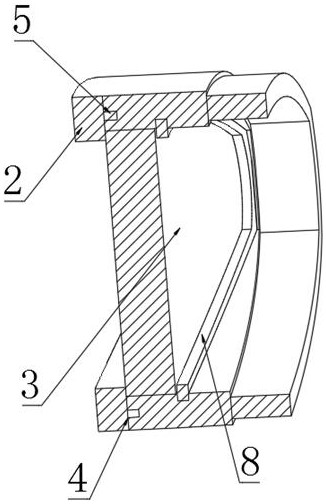

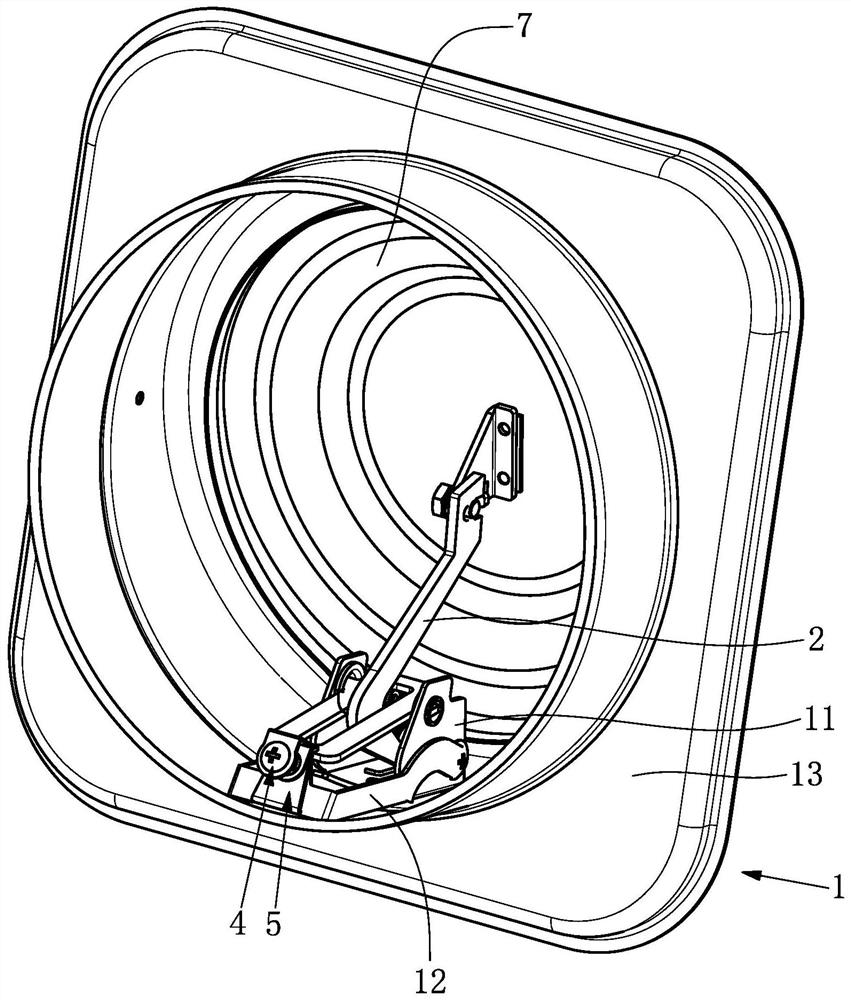

A high-compromise swimming goggle that is easy to adapt and adjust

Owner:福建省胜佰龙体育用品科技有限公司

Locking structure

PendingCN111609183AWork reliablyNo separation problemsCheck valvesEqualizing valvesCheck valveStructural engineering

The invention relates to a locking structure, and solves the problem that a fire-proof check valve automatically loses efficacy under a low-temperature environment. The locking structure comprises a foundation bed, a connecting rod, an elastic element and a stirring sheet, wherein one end of the elastic element is arranged on the foundation bed; and the other end of the elastic element is arrangedon the stirring sheet and is used for driving the stirring sheet to rotate relative to the foundation bed. The locking structure also comprises a fusing component, a fastening mechanism and a stop plate, wherein the fastening mechanism is arranged on the foundation bed; the stop plate is arranged on the fastening mechanism and is provided with a locking position and an unlocking position; when the fusing component works, the stop plate is fixed on the locking position through the fusing component, and the stop plate prevents the stirring sheet from rotating relative to the foundation bed; andwhen the fusing component does not work and the fusing component is separated from the stop plate, the elastic element pushes the stop plate to the unlocking position through the stirring sheet.

Owner:梅慧

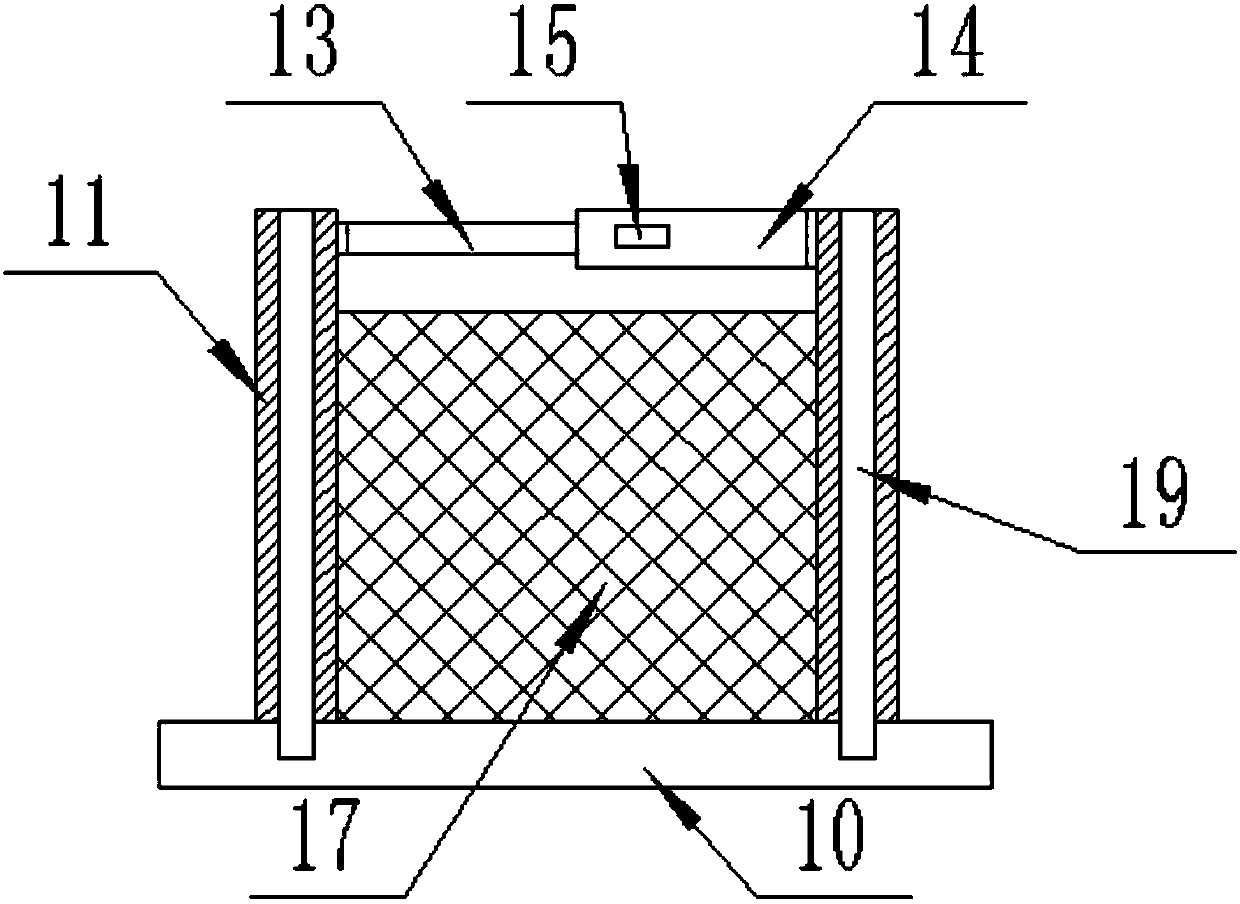

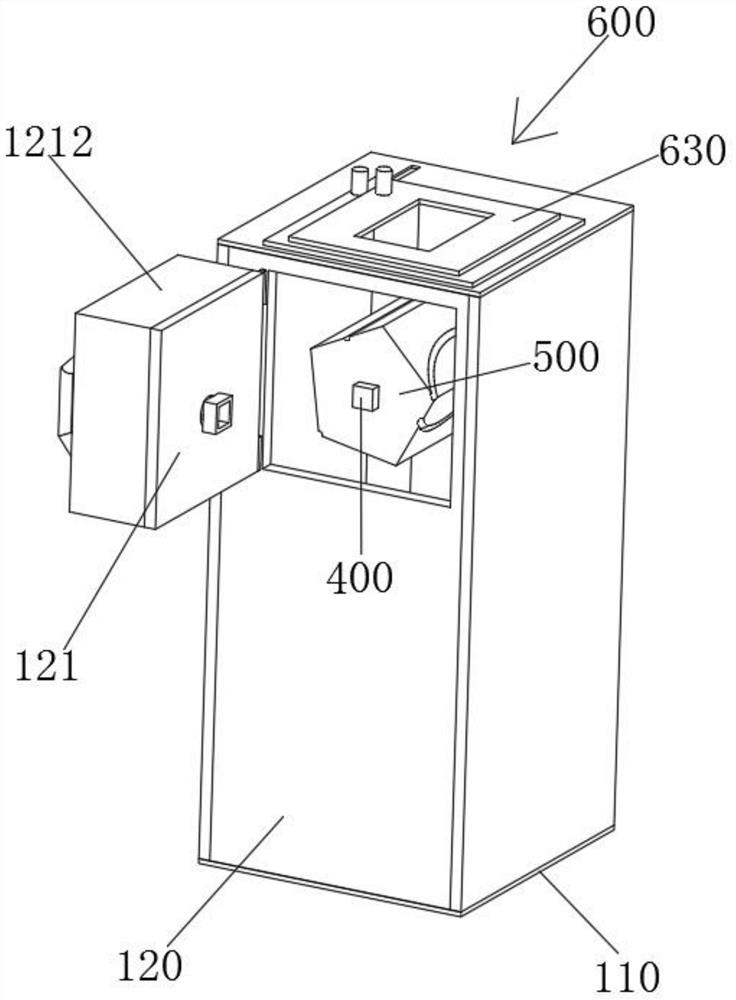

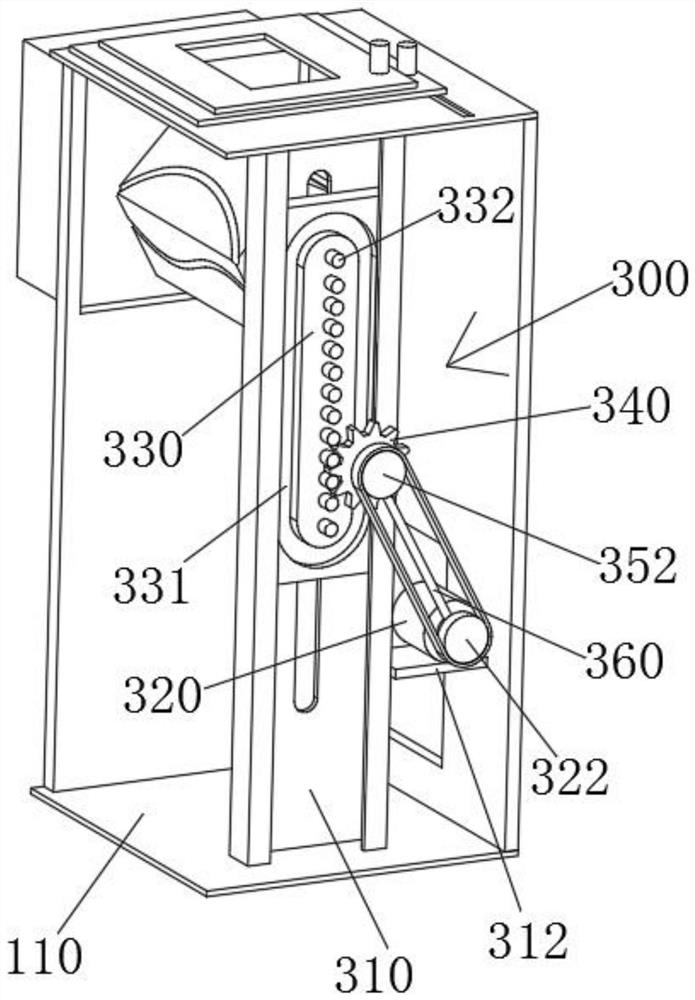

Deep suture operation practical training equipment for cardiac surgery

ActiveCN112331050AEasy to replaceEasy to change the angleCosmonautic condition simulationsEducational modelsGear wheelElectric machinery

The invention relates to the technical field of medical operation practical training equipment, in particular to cardiac surgery deep suture operation practical training equipment. The equipment comprises a box body, and the box body comprises a bottom plate, the top faces of the four edges of the bottom plate are fixedly connected with a first baffle, a second baffle, a third baffle and a fourthbaffle correspondingly, wherein a first rectangular hole is formed in the outer side wall of the top of the first baffle; a first cover plate is rotatably connected to the outer side of the first rectangular hole through a hinge, a first fixed plate is fixedly connected to the outer side of the first cover plate, a first motor is fixedly connected to the top surface of the first fixed plate, and adepth adjusting mechanism is arranged at one end of the top surface of the bottom plate. According to the device, a second motor drives a first belt wheel to rotate, so a gear is in engaged transmission with a transmission column, a sliding plate moves up and down in a supporting plate, a square rotating shaft drives a suturing block to move up and down in a box body, the distance from the suturing block to the open end of the box body is conveniently changed, and suturing training at different depths is realized.

Owner:南京智昊佳教育科技有限公司

Steel discharger

InactiveCN111266418ASimplify the delivery processImprove adaptabilityMetal rolling arrangementsFailure rateAssistive device/technology

The invention discloses a steel discharger and relates to the technical field of steel rolling auxiliary equipment. The steel discharger comprises at least two discharge devices. Each discharge devicecomprises a deflector rod base, a deflector rod, a reduction motor, a long shaft and a long shaft rocker arm, wherein one end of the deflector rod is hinged to the deflector rod base; the long shaftis driven by the reduction motor and connected with the reduction motor and is perpendicular to the deflector rod; and one end of the long shaft rocker arm is hinged to the deflector rod, and the longshaft rocker arm is fixedly connected to the long shaft and is perpendicular to the long shaft. The two discharge devices are symmetrically arranged. Through the steel discharger, the supporting areafor bearing steel billets is increased, the steel billet conveying link is simplified, and the service life of the steel discharger is prolonged. The steel discharger is simple in structure and stable in operation. The failure rate of equipment is reduced. The adaptability of the steel discharger to different sizes of steel billets is improved.

Owner:XINXING DUCTILE IRON PIPES CO LTD

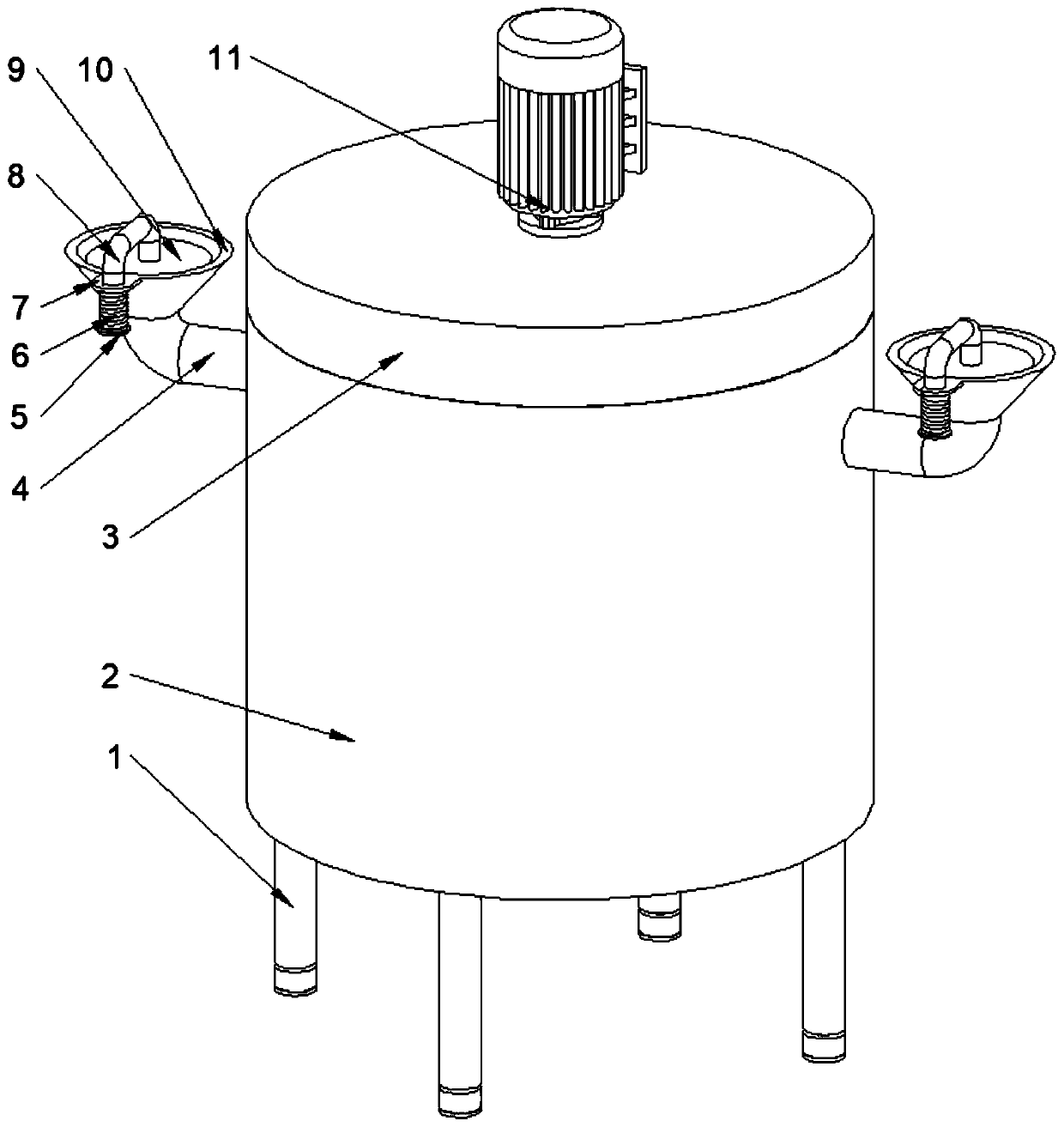

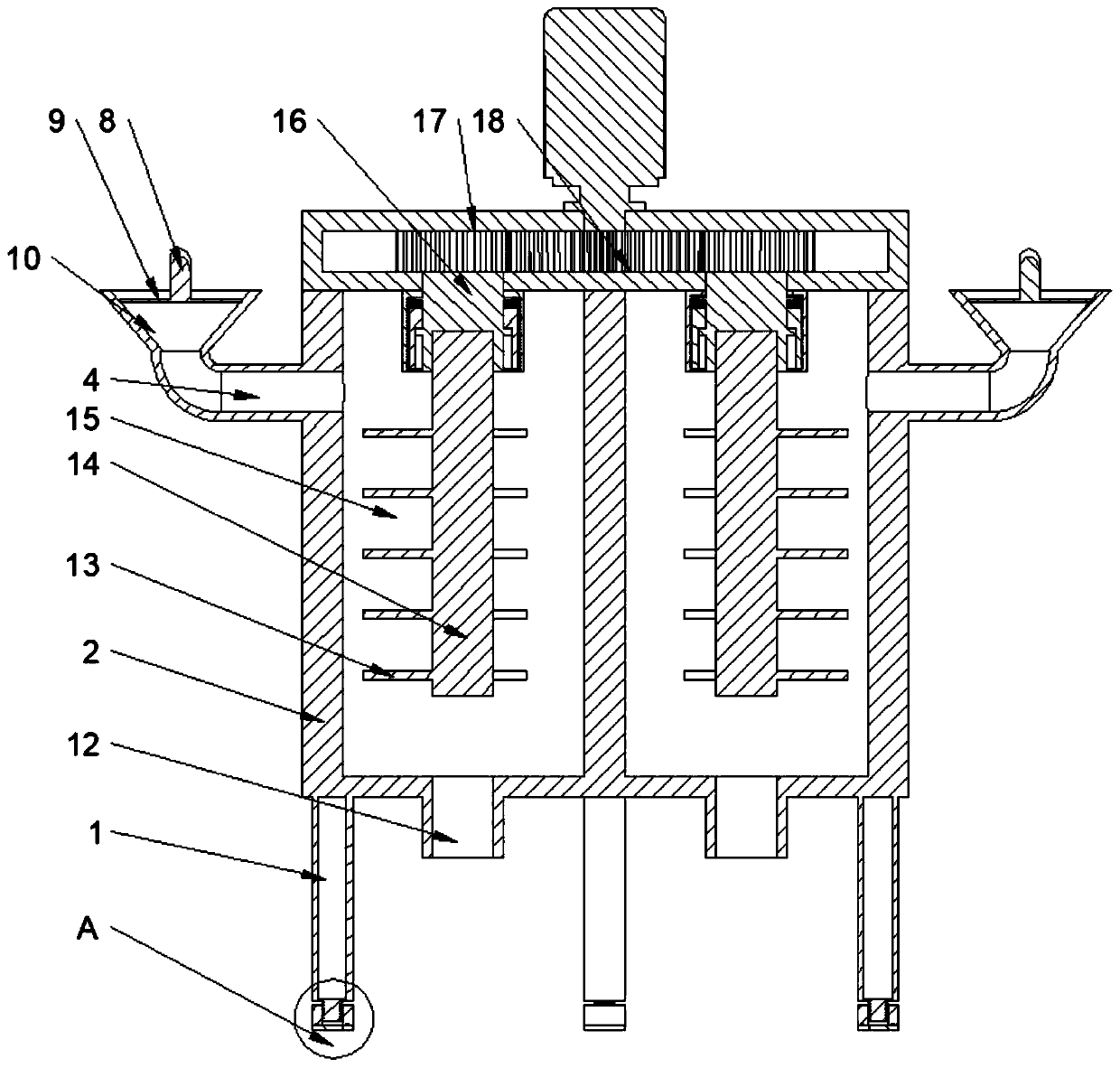

Stirring equipment for production of non-dangerous chemicals

InactiveCN110961005AEasy to snap inNo rotationRotary stirring mixersTransportation and packagingEngineeringStructural engineering

Owner:徐州聚西廷新型材料科技有限公司

Heat dissipation device of Internet of Things switch

InactiveCN112292012AImprove cooling effectReduce the temperatureModifications by conduction heat transferThe InternetEngineering

The invention discloses a heat dissipation device of an Internet of Things switch, and the device comprises a heat dissipation device body, which is of a hollow cuboid structure, a heat dissipation fan is installed in the heat dissipation device body, a ventilation box is disposed below the heat dissipation fan, and the ventilation box is located in a bottom plate of the heat dissipation device body. The two ends of the ventilation box are each connected with one ventilation pipe in a communicating mode, the ventilation pipes penetrate through the two side walls of the heat dissipation devicebody and extend to the upper portion of the heat dissipation device body, through the arrangement of Z-shaped heat dissipation holes, the time consumed when heat passes through limiting plates is longer, and more heat is transferred to the limiting plates, through the arrangement of a cover plate, dust can be blocked for the Internet of Things switch, sudden impact of objects above is prevented, different limiting can be conducted according to the type of the Internet of Things switch through the matching effect of the sliding grooves and the sliding blocks, the application range is wide, thedistance between the limiting plates is conveniently changed, and air cooling heat dissipation is conducted on the Internet of Things switch by arranging a cooling fan.

Owner:钟华新

Fireproof check valve

The invention relates to a fireproof check valve in order to solve the problem that a fireproof check valve is out of operation automatically under a low-temperature environment. The fireproof check valve comprises a body, a valve plate, a connecting rod, an elastic element and a shifting plate. The body is provided with an exhaust port. The connecting rod is connected with the valve plate and thebody and used for driving the valve plate to close the exhaust port. One end of the elastic element is arranged on the body, the other end of the elastic element is arranged on the shifting plate, and the elastic element is used for driving the shifting plate to rotate relative to the body. The fireproof check valve further comprises a fusing mechanism and a stop plate. The stop plate is clampedbetween the fusing mechanism and the body. The stop plate is provided with a rotation stop part. When the rotation stop part is clamped between the fusing mechanism and the body, the rotation stop part is arranged on the shifting plate to stop the shifting plate from rotating relative to the body. After the fusing mechanism does motion, the stop plate moves relative to the body, and the rotation stop part is separated from the shifting plate.

Owner:梅慧

An integrated device for a garden with a garbage can and a flower stand that can be solidly separated

ActiveCN110921148BEasy to pourReduce weightRefuse receptaclesAgricultural scienceAgricultural engineering

The invention discloses a solid-liquid separable garbage can and flower stand integrated device for gardens. The solid-liquid separable garbage can and flower stand integrated device for the gardens comprises a supporting frame, second bases and threaded rods, wherein a storage box is mounted below the inner side of the supporting frame, the supporting frame is mutually connected with a garbage can body through a connecting shaft on the inner side, a filtering net is fixed inside the garbage can body, the supporting frame is located above a bearing platform, the two sides of a water collectingcavity are mutually connected with protective sleeves through rubber pipes, the threaded rods penetrate through the surfaces of flower stand bottom plates and the surfaces of flower stand top platescorrespondingly, rotating shafts are mutually connected with blades through mounting sleeves fixed on the outer surfaces of the rotating shafts, and the blades are located above the flower stand top plates. According to the solid-liquid separable garbage can and flower stand integrated device for the gardens, the structure in which the garbage can body and flower stands are mutually connected is combined with the ecological gardens better, liquid in a garbage can is utilized by the flower stands for secondary utilization, meanwhile, peculiar smell in the garbage can is purified through the flower stands, and the use is convenient.

Owner:浙江铭翔建设有限公司

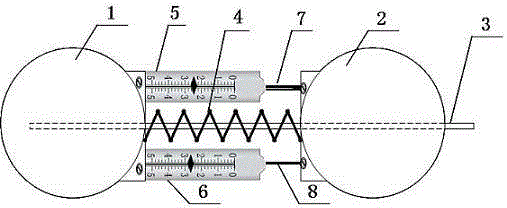

Intermolecular interaction force demonstrator

InactiveCN103915019BEasy to change the distanceImage Intuitive InteractionEducational modelsEngineeringDynamometer

The invention relates to an instrument for demonstrating intermolecular interaction force, which comprises a first small ball, a second small ball, a balance shaft, a spring, a first dynamometer, a second dynamometer, a rubber strip and a metal connecting rod . The first small ball and the second small ball are connected together by a spring; the scales of the first dynamometer and the second dynamometer are reversed, one end is fixed on the first small ball, and the other end is respectively passed through a rubber strip and a metal connecting rod Connect the second ball. The present invention can effectively make the intermolecular interaction force exist simultaneously, increase at the same time, decrease at the same time, when it is equal, when the attractive force is greater than the repulsive force, and when the attractive force is smaller than the repulsive force, etc. The physical law of the solution is modeled, dynamic, and visualized.

Owner:师海满

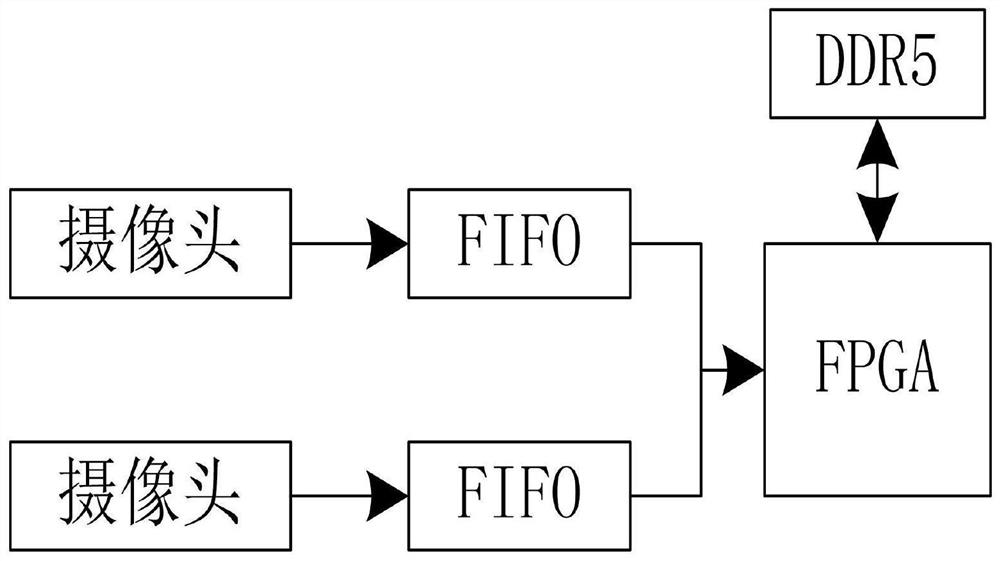

Binocular camera synchronous control method

PendingCN113411562AEasy to change the distanceEasy to adjust the size of the viewing areaSteroscopic systemsSynchronous controlRadiology

The invention provides a binocular camera synchronous control method, which comprises the following steps: adjusting the position between two cameras, adjusting the distance between the two cameras arranged on a base through a control mechanism, and recording the distance between the two cameras; controlling two cameras through an FPGA and sending synchronous control signals through the FPGA to control the two cameras to synchronously collect images, wherein the two cameras send two pieces of image data to the FPGA in parallel through FIFO. According to the invention, the situations that the synchronism of a binocular camera is poor, the development of a dual-camera function is limited, the performance and advantages of the binocular camera cannot be played to the greatest extent, and the visual range of the binocular camera cannot be changed are avoided.

Owner:合肥朗云物联科技有限公司

Novel macromolecule piezoelectric material annealing treatment device

The invention discloses a novel macromolecule piezoelectric material annealing treatment device. The novel macromolecule piezoelectric material annealing treatment device comprises a transportation component and a pre-cooling assembly. A conveying assembly and a heating assembly are arranged on one side of the pre-cooling assembly. The conveying assembly is located on one side of the heating assembly. A controller is fixed to the end, close to the heating assembly, of the conveying assembly. Hydraulic pumps are arranged on the side wall of the conveying assembly. The controller is electricallyconnected with an outer power source. The hydraulic pumps are electrically connected with the controller. A conveying component is arranged in the conveying assembly. An S-shaped movable baffle and an S-shaped fixed baffle are arranged in a conveying cavity, a workpiece transported through the conveying component is guided through the S-shaped movable baffle and the S-shaped fixed baffle, the workpiece straight line path is changed into the S-shaped path, the workpiece motion stroke is increased under the situation that the length of the conveying cavity is not changed, accordingly, the workpiece cooling time is prolonged, and the workpiece can better achieve the cooling condition.

Owner:CHANGXING CAZENOVE FUNANCE IND CO LTD

Pre-setting device for low-temperature stability-maintaining polyurethane filament

PendingCN113186675ADoes not affect water efficiencyImprove the heating effectLiquid/gas/vapor removal by squeezing rollersTextile treatment machine arrangementsElectric machineEngineering

The invention relates to the technical field of polyurethane material production, and discloses a pre-setting device for low-temperature stability-maintaining polyurethane filament. The device comprises a water passing tank; guide wheels movably sleeve two sides of an inner cavity of the water passing tank; a polyurethane filament body is movably connected to the outer sides of the guide wheels; a moving opening is formed in the upper part of the rear side of the water passing tank; a first motor movably sleeves an inner cavity of the moving opening; and a moving block is fixedly mounted on the rear side of the water passing tank. According to the pre-setting device for the low-temperature stability-maintaining polyurethane filament, a heater is arranged in the inner cavity of the water passing tank, so that water in the inner cavity of the water passing tank is conveniently heated; and a screw rod is driven to rotate through the moving block as a driver, the first motor is conveniently driven to move along the interior of the inner cavity of the moving opening due to the fact that the screw rod is in meshed connection with the first motor, and a connecting strip and an inclined plate are driven to move in the inner cavity of the water passing tank, so that the water in the water passing tank can be uniform in temperature, and the water passing efficiency of the polyurethane filament body is not affected.

Owner:JINMING KNITTING

A self-shaping method for gas refining quartz glass anchorage

ActiveCN108793692BEasy to change the distanceAchieve physical contactGlass shaping apparatusGlass productionMaximum diameterPhysical chemistry

The present invention is a self-shaping method for gas-refining quartz glass anchors. The steps are as follows: add silicon material into a quartz hammering machine, melt and flow into the furnace cavity of a furnace under the action of a high-temperature hydrogen-oxygen flame, and perform deposition and heap-dissolution operations. During the deposition growth flow process, concentric fused glass cylindrical quartz glass anchorages with different diameters are formed at different deposition heights; when the height grows to 20mm~50mm, self-shaping begins, and the quartz fire head and fused glass cylindrical quartz The glass anchors move radially towards the inner wall of the furnace cavity, so that the maximum diameter of the molten glass cylindrical quartz glass anchor will rub against the inner wall of the furnace cavity, resulting in deformation, so that the product's appearance size can reach the upper and lower diameters within the height range. requirements to obtain products. The appearance size of the product is adjusted by using the friction force between objects, so as to precisely control the appearance of the quartz glass anchor, reduce the appearance defects of the product, improve efficiency, and reduce production costs.

Owner:江苏省晶瑞石英工业开发研究院有限公司

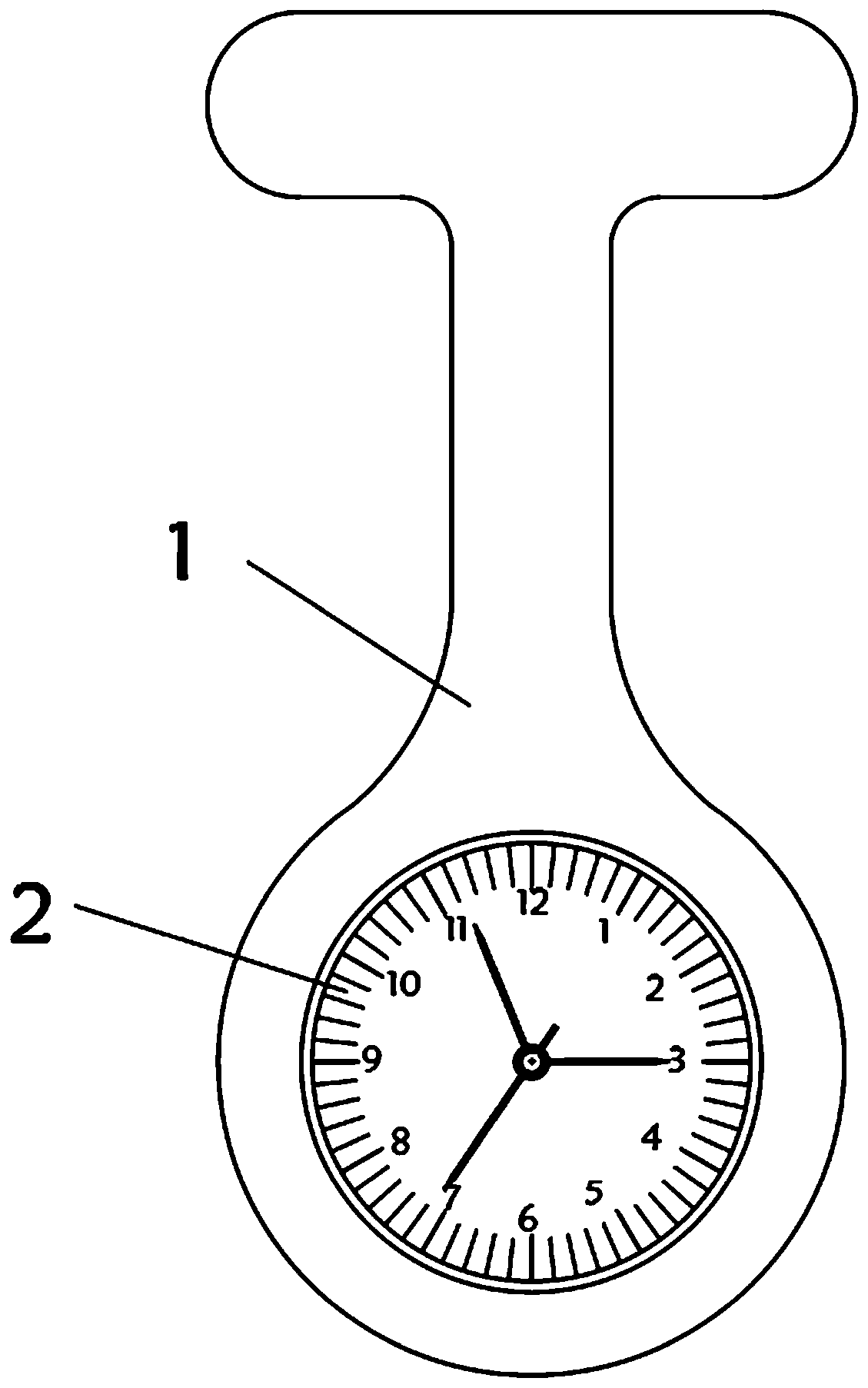

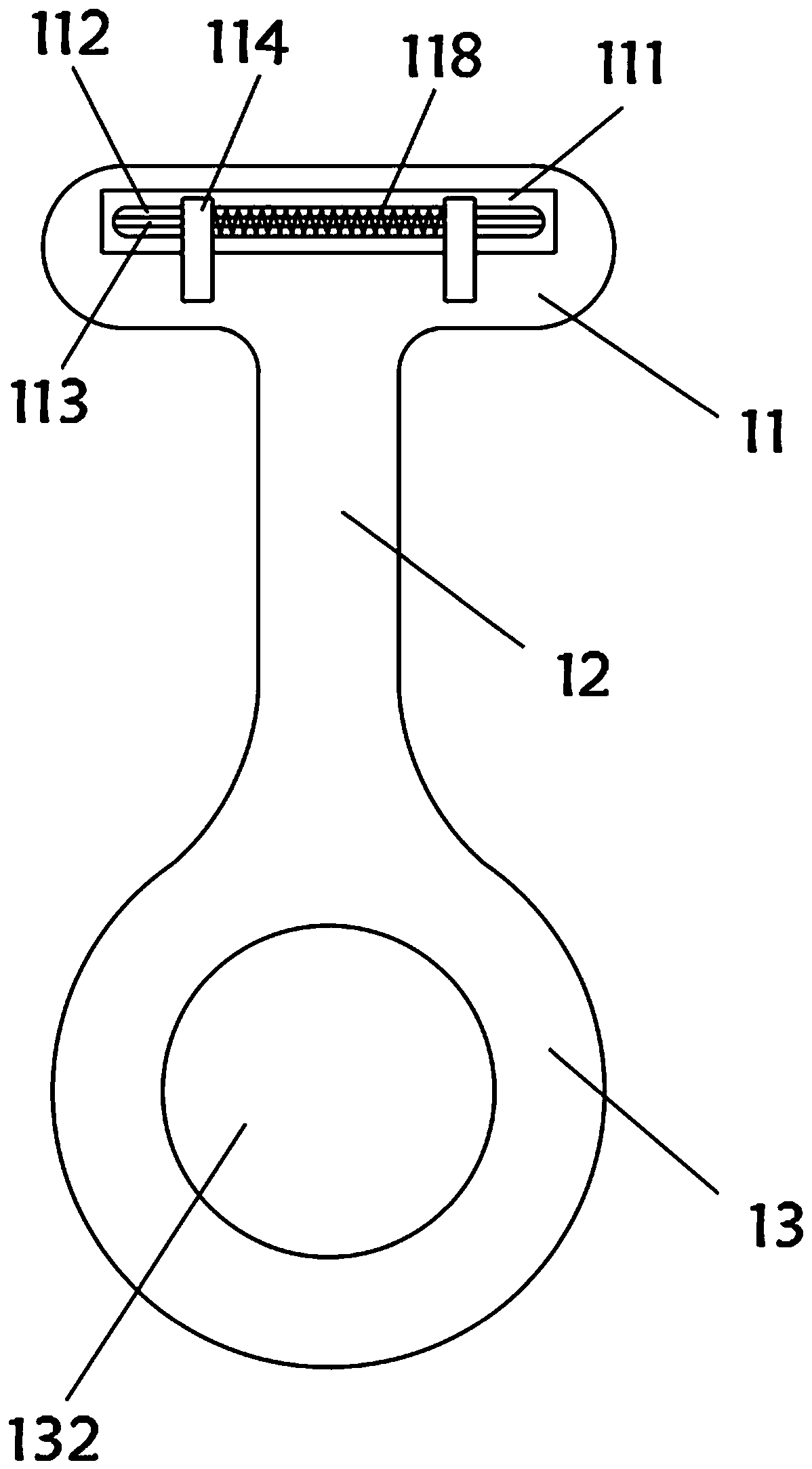

Artificial intelligence voice nurse watch

InactiveCN111427254AEasy to change the distanceAdaptableVisual indicationsTime-pieces with integrated devicesInformation functionEngineering

The invention relates to the technical field of nurse watches, in particular to an artificial intelligence voice nurse watch. The watch comprises a wearing band and a circular watch embedded in the wearing band. The wearing band is sequentially provided with a wearing part, a connecting part and an installing part from top to bottom; the wearing part and the connecting part are of an integrally-formed structure, a pair of clamps are arranged on the outer wall of the installing plate, connecting rods slidably connected with the sliding grooves are installed on the backs of the clamps, sliding rings slidably connected with the installing columns are installed at one ends of the connecting rods, and a spring is installed between the two sliding rings. The invention discloses an artificial intelligence voice nurse watch. The sliding ring slides on the installing column; the connecting rod slides in the sliding groove, so that the position of the clamp on the installing plate can be adjusted at will, the clamping distance can be changed conveniently, and the adaptability is high; the memo information module is arranged, the memo information time is achieved, countdown is formed, and thememo information function is provided for medical staff; the voice reminding module is arranged, and the reminding effect is achieved through voice broadcasting.

Owner:JIANGSU CANCER HOSPITAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com