Assembled cross arm structure applied to electric tower

An assembled and electric tower technology, which is applied in the field of electric power iron components, can solve the problems of easy rust, weak corrosion resistance, poor wind resistance of a single cross-arm, frequent lightning conduction accidents, etc., to improve wind resistance, Reduce the difficulty of handling and improve the effect of carrying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Next, the technical solutions in the embodiments of the present invention will be described in connection with the drawings of the embodiments of the present invention, and it is understood that the described embodiments are merely the embodiments of the present invention, not all of the embodiments.

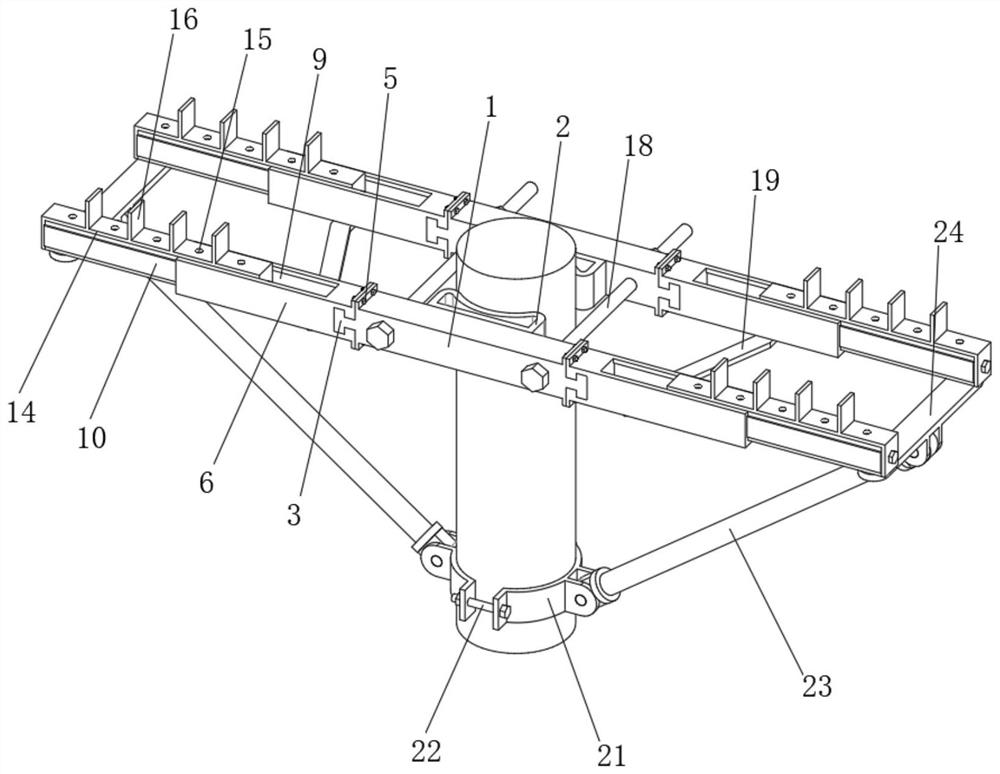

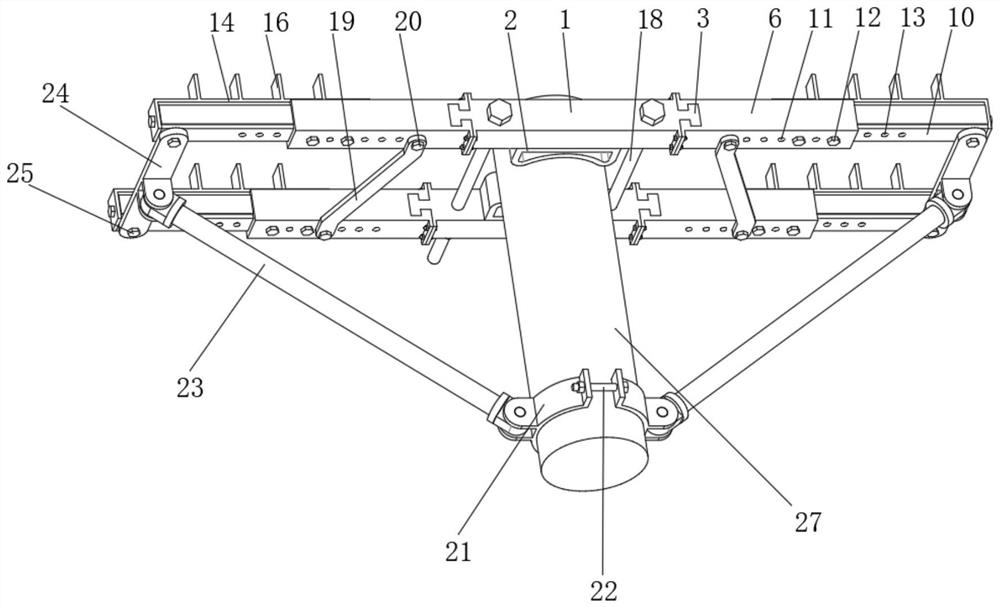

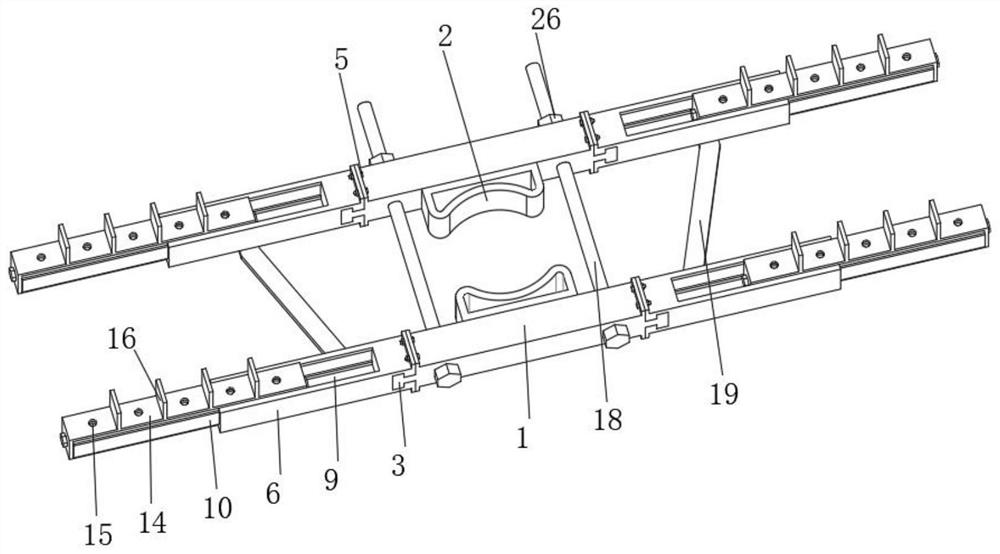

[0024] See figure 1 and Figure 4 The present invention provides a technical solution: an assembled crossburable structure applied to the electric rejection, including the first cross-load assembly 1, the electric rectangra 27, the inner side fixed connection of the first crossover assembly 1 has a clamping block. 2, the inside of the clamping block 2 is circular, the first crossover assembly 1 is symmetrically distributed on both sides of the electric rejection 27, clamping the block 2 is clamped outside the electric rejection 27, the first crossover assembly 1 The left and right ends are fixedly connected to the connecting hoe 3, and the first cross-load assembly 1 is provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com