Early fault detection method for gearbox

A technology of early failure and detection method, applied in the direction of measuring device, testing of mechanical parts, testing of machine/structural parts, etc., can solve the problems of weak early failure characteristics, difficult extraction and failure characteristics of gearboxes, and avoid major economic problems. The effect of loss, high detection rate and fast detection speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

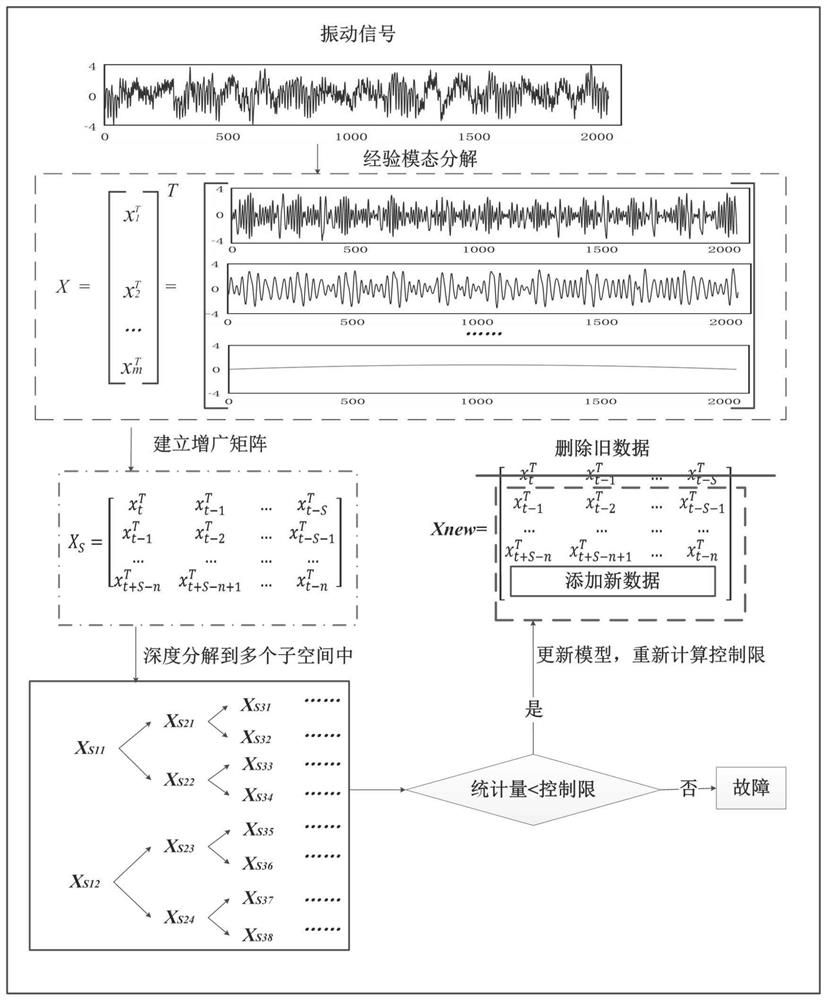

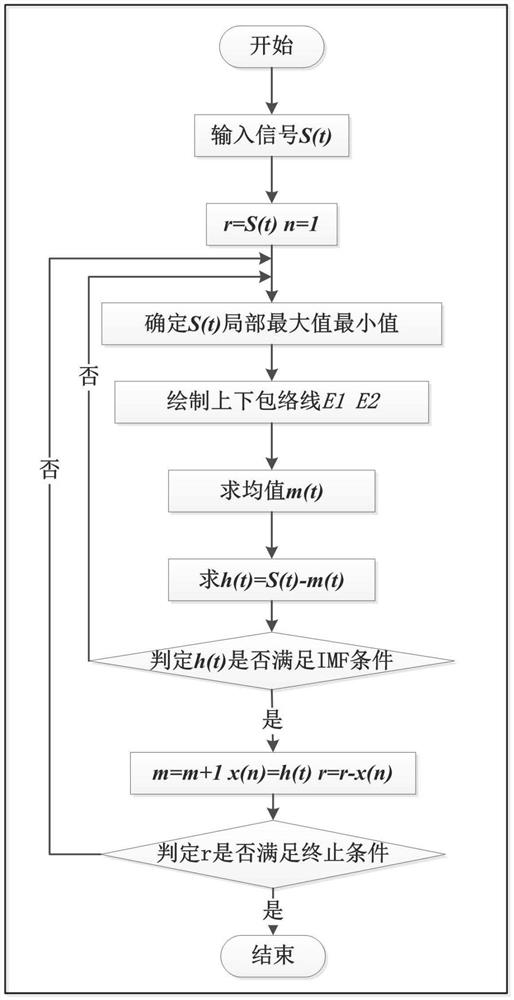

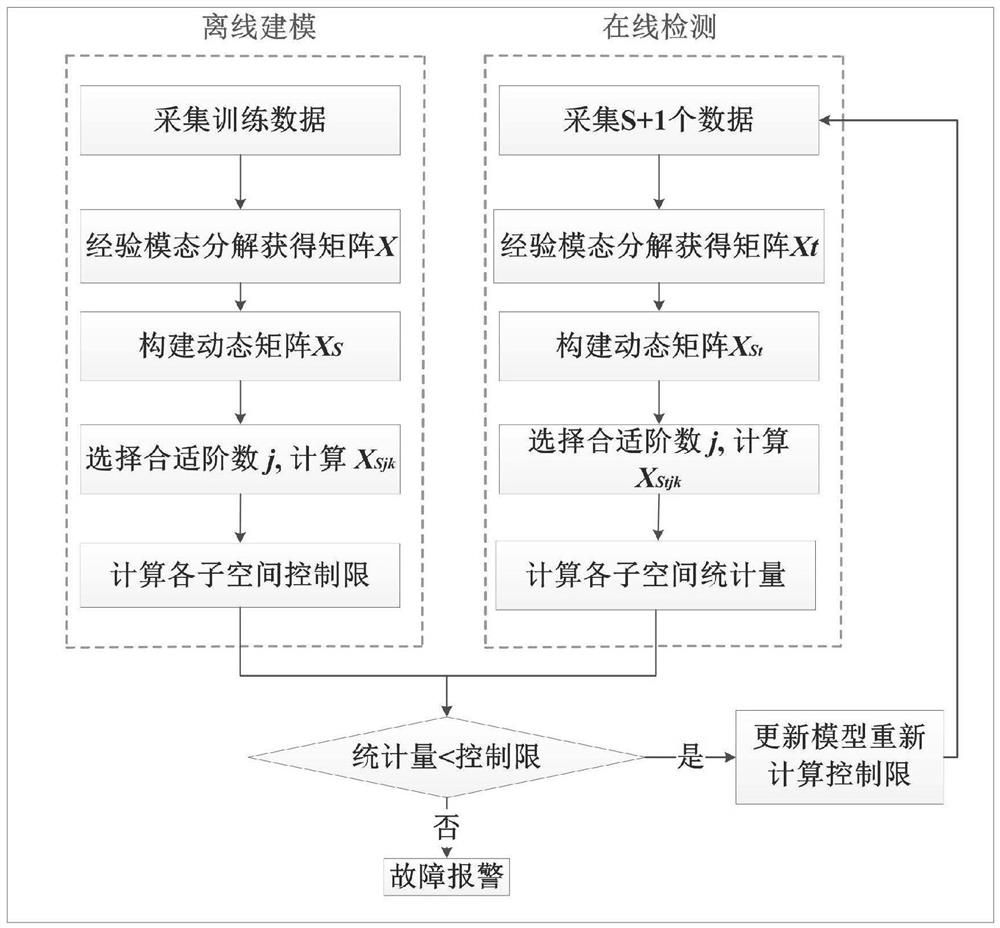

[0034] Early fault detection of gearboxes has become an important branch and research hotspot of intelligent maintenance. Some existing methods basically detect early faults based on models and signal processing, but these methods have complex modeling, low model accuracy, poor timeliness for early fault detection, and inaccurate detection results. Therefore, the present invention combines the idea of depth decomposition theorem to divide the collected data in detail, so as to extract the features of weak fault information under strong noise background. At the same time, using the sliding window algorithm, taking into account the time series correlation of the data, the early fault detection ability is improved.

[0035] This embodiment takes the gearbox commonly used in mechanical equipment as an example, such as figure 1 As shown, the present invention adopts an early fault detection method based on deep recursive dynamic principal component analysis, and the specific ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com