A performance test system for high-parameter single-atom working fluid equipment

A test system and high-parameter technology, applied in the testing of machines/structural components, instruments, measuring devices, etc., can solve problems such as hidden dangers of system device safety, single working condition, equipment risks, etc., to ensure accuracy, improve efficiency, The effect of reducing trial costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

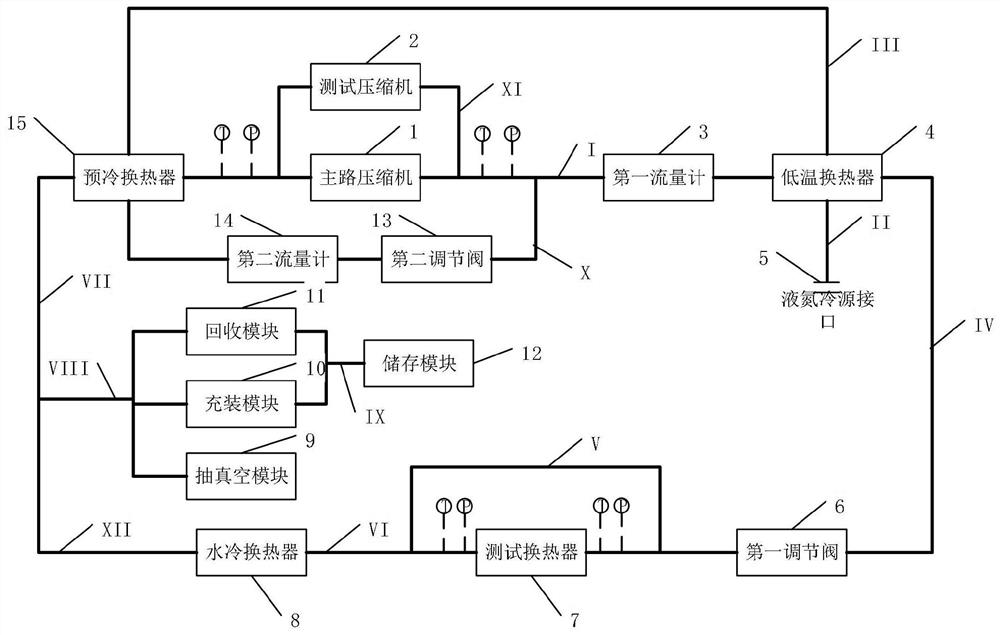

[0081] Embodiment 1. Only the performance of the test compressor 2 is tested. The test medium is helium, the critical pressure is 0.228MPa, and the critical temperature is 5.19K. The test method is as follows:

[0082] Utilize the evacuation vacuum module 9 of the air source unit to evacuate the test system, so that the test system is in a high vacuum state;

[0083] Close the main circuit compressor 1 and the test heat exchanger 7, open the test compressor 2 and other equipment and other pipelines in the test system; according to the test parameter requirements, use the storage module 12 and the filling module 10 of the gas source unit Fill the test system with monoatomic working fluid to the specified pressure P, and the specified pressure P exceeds the critical pressure;

[0084] Adjust the test compressor 2 to the test parameters, open the liquid nitrogen cold source interface 5 to fill the cryogenic unit with liquid nitrogen, and cool the monoatomic medium in the test sys...

Embodiment 2

[0087] Embodiment 2. Only the performance of the test heat exchanger 7 is tested. The test medium is helium, the critical pressure is 0.228MPa, and the critical temperature is 5.19K. The test method is as follows:

[0088] Utilize the evacuation vacuum module 9 of the air source unit to evacuate the test system, so that the test system is in a high vacuum state;

[0089]Close the test compressor 2 and the test heat exchanger bypass V, open the test heat exchanger 7 and other equipment and other pipelines in the test system; Module 10 fills the test system with a single-atom working fluid to a specified pressure P, and the specified pressure P exceeds the critical pressure;

[0090] Adjust the main circuit compressor 1 and the test heat exchanger 7 to the test parameters, open the liquid nitrogen cold source interface 5 to fill the cryogenic unit with liquid nitrogen, and cool the monoatomic medium in the test system;

[0091] By adjusting the pressure, temperature and flow of...

Embodiment 3

[0093] Embodiment three, test the combined performance of the test compressor 2 and the test heat exchanger 7, the test medium is helium, the critical pressure is 0.228MPa, and the critical temperature is 5.19K, the test method is as follows:

[0094] Utilize the evacuation module 9 of the air source unit to evacuate the test system, so that the test system is in a high vacuum state;

[0095] Close the main circuit compressor 1 and the test heat exchanger bypass V, open the test compressor 2, test heat exchanger 7, other equipment and other pipelines in the test system; according to the test parameter requirements, use the gas source unit The storage module 12 and the filling module 10 fill the test system with a single-atom working fluid to a specified pressure P, and the specified pressure P exceeds the critical pressure;

[0096] Adjust the test compressor 2 and the test heat exchanger 7 to the test parameters, open the liquid nitrogen cold source interface 5 to fill the cr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com