PVA layer manufacturing method, polarizer, display device and mobile terminal

A manufacturing method and display device technology, applied in the direction of optics, optical elements, polarizing elements, etc., can solve the problems of bubble lines, thermal expansion and contraction, etc., and achieve the effect of avoiding bubble lines and ensuring light transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

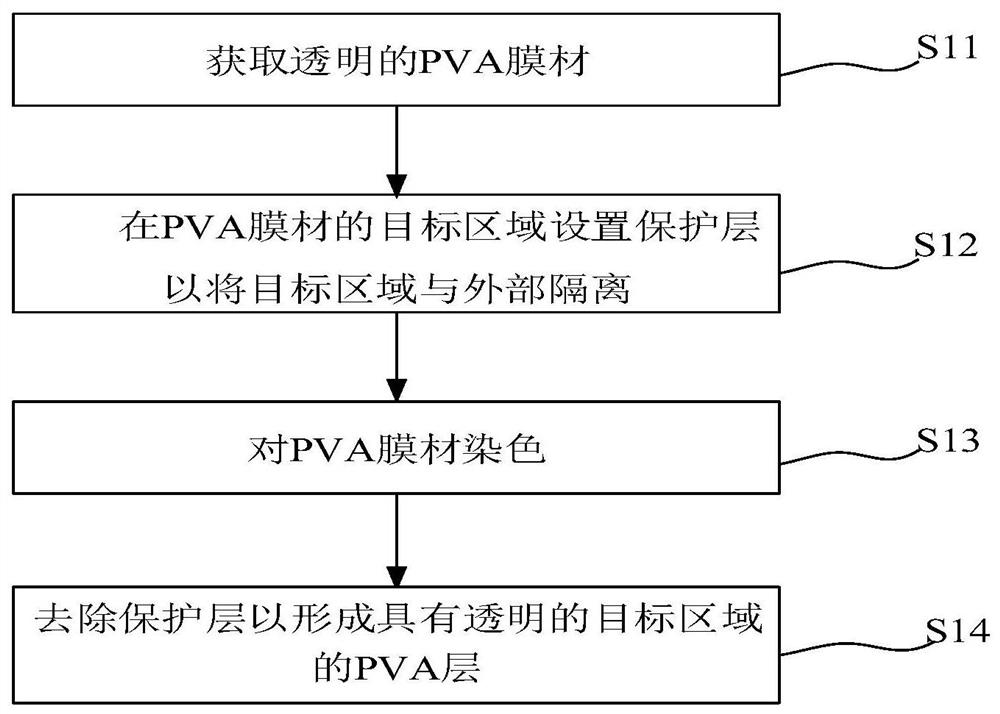

[0033] This embodiment provides a method for manufacturing a PVA layer, which can be applied to mobile terminals such as mobile phones. see figure 2 , the production method includes the following steps:

[0034] Step S11, obtaining a transparent PVA film material.

[0035] PVA film is also called polyvinyl alcohol film, which is usually a white flake solid. Polyvinyl alcohol film is an important chemical raw material for the manufacture of polyvinyl acetal, gasoline-resistant pipes and adhesives. In the embodiment of the present application, the untreated PVA film material is transparent and permeable to light.

[0036] Wherein, after the step of obtaining the transparent PVA film material, it includes: performing swelling treatment on the PVA film material.

[0037] Specifically, after the transparent PVA film material is obtained, the transparent PVA film material is swollen with water, and the PVA film material after the swollen treatment is cleaned to filter the impuri...

Embodiment 2

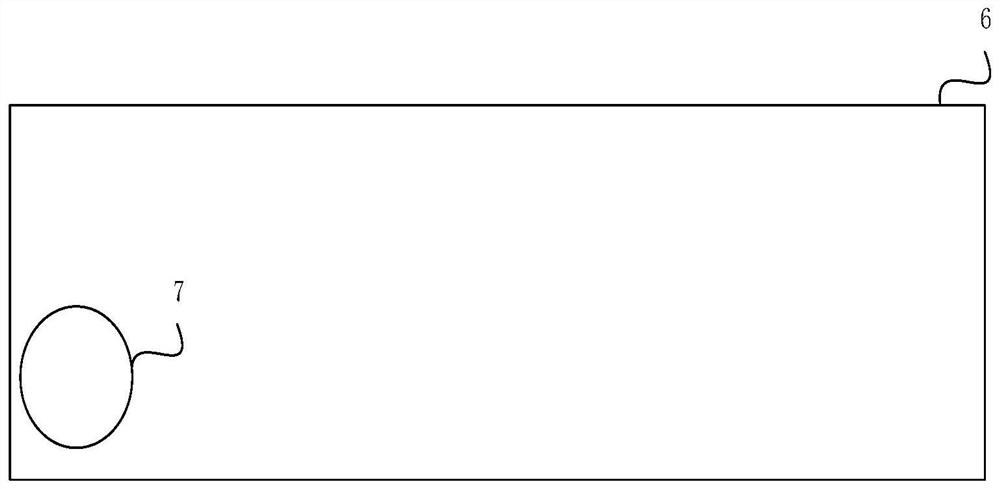

[0056] This embodiment provides a polarizer, such as image 3 As shown, it includes the PVA layer made by using the method for making the PVA layer in the first aspect. The PVA layer 6 includes a target area 7 , and the target area 7 is a preset punching position in the PVA layer 6 .

[0057] Specifically, the schematic diagram of the structure of the polarizer in the prior art is figure 1The hollow structure in , it can be seen that the hollow structure in the existing polarizer 3-1 is the perforated position. In the existing process, when attaching the polarizer, it is necessary to set the polarizer glue on the preset polarizer area on the substrate. After the polarizer is pasted, the polarizer beyond the predetermined polarizer area is cut, which is easy to cause damage to the polarizer. , For the perforated screen polarizer, the finished polarizer needs to be cut, which further damages the polarizer.

[0058] However, the PVA layer 6 in the polarizer provided by the pre...

Embodiment 3

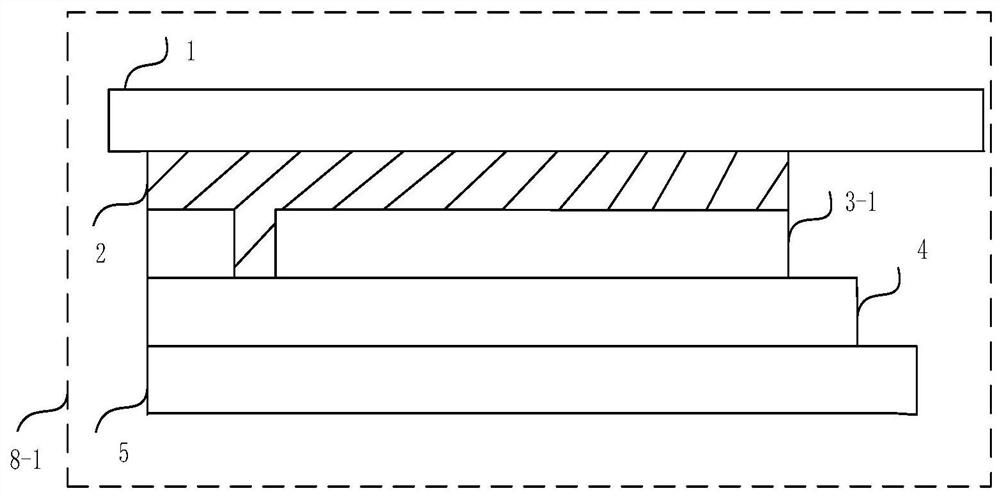

[0063] This embodiment provides a display device, such as Figure 4 As shown, the display device includes an optical module 8-2 and a light source module, the optical module 8-2 covers the top of the light source module, and the optical module 8-2 includes The polarizer 3-2.

[0064] In one possible implementation, see Figure 4 , the improved optical module 8-2 includes a TFT glass layer 5 , a CF glass layer 4 , an OCA adhesive layer 2 and a cover layer 1 . The TFT glass layer 5 and the CF glass layer 4 can be made of transparent material, and the cover layer 1 is also made of transparent material, so the light emitted by the light source module can pass through.

[0065] In another possible implementation manner, the OCA adhesive layer 2 is attached to the upper surface of the polarizer 3-2, and the CF glass layer 4 is attached to the lower surface of the polarizer 3-2. In order to better adhere the polarizer 3-2 to the cover plate 1, it can be filled with OCA glue to for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com