Rapid sintering furnace for metallic oxide ceramic material and sintering process of rapid sintering furnace

An oxide ceramics, rapid sintering technology, applied in the field of medical materials, can solve the problems of short life, unstable process, low production capacity, etc., to achieve the effect of increased production capacity, shortened process time, and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

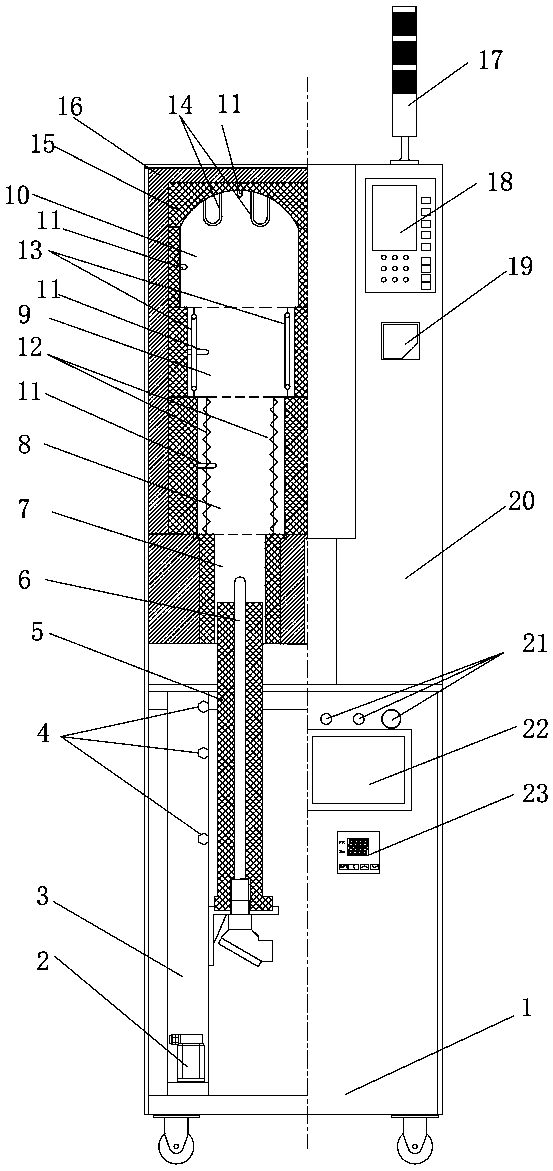

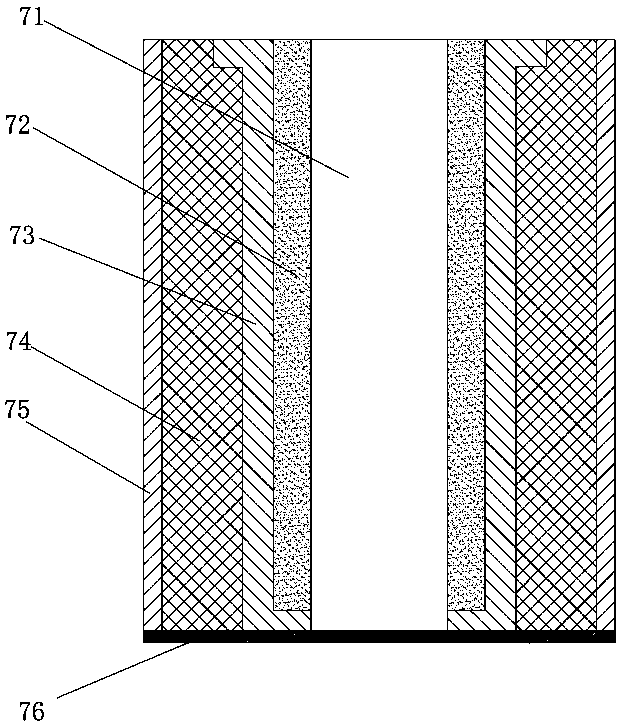

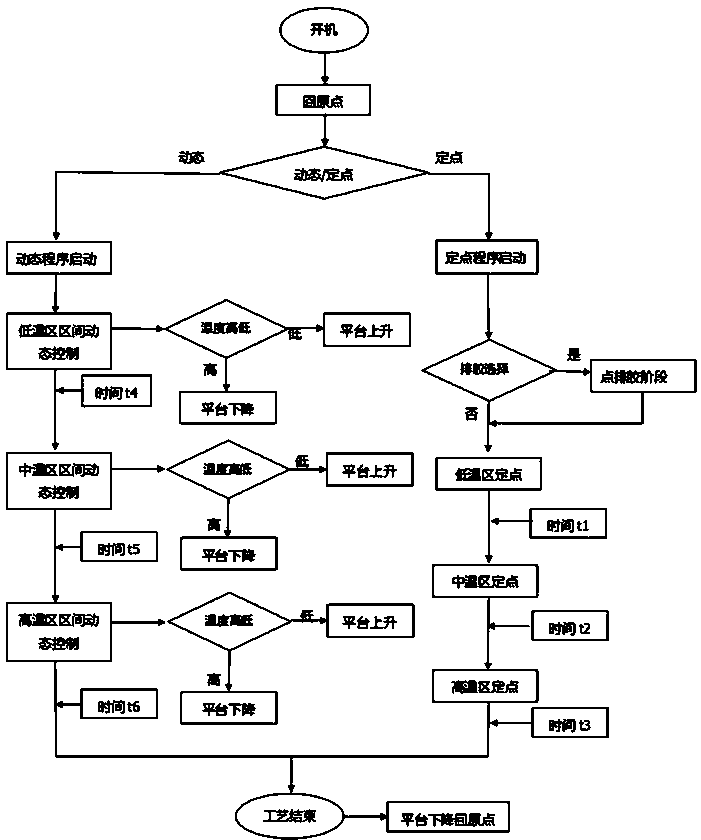

[0033] Embodiment: a kind of fast sintering furnace of metal oxide ceramic material, such as figure 1 Shown, comprise frame 1, the furnace chamber that is provided with downward opening on the frame. The furnace is sequentially provided with a high temperature chamber 10 , a medium temperature chamber 9 and a low temperature chamber 8 which communicate with each other from top to bottom. The furnace wall of the high-temperature chamber 10 is provided with a silicon-molybdenum heating element 14 for tertiary heating; the furnace wall of the medium-temperature chamber is provided with a silicon-carbon heating element 13 for secondary heating; the furnace wall of the low-temperature chamber is provided with There are alloy resistance wires 12 for primary heating; thermocouples 11 are respectively provided on the furnace walls of the high temperature chamber, medium temperature chamber and low temperature chamber. The heating temperature of the high-temperature chamber is 1200-17...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com