Tool bit abrasion monitoring method and tool bit abrasion monitoring system

A monitoring system and cutter head technology, applied in closed-circuit television systems, image data processing, instruments, etc., can solve the problems of high cost, large amount of silicon wafer consumables, and high PM frequency of the machine, achieving simple structure, easy installation, The effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 3 example

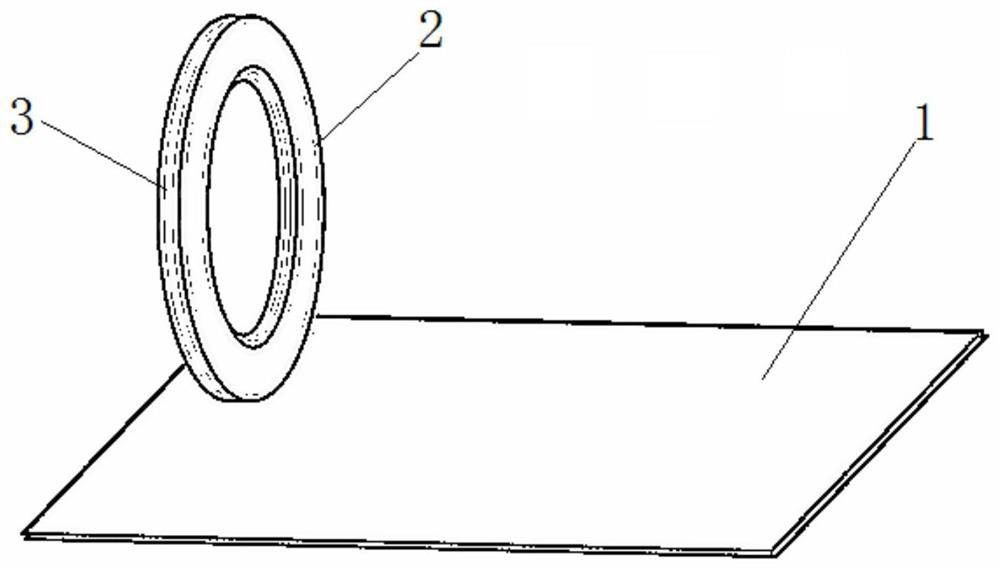

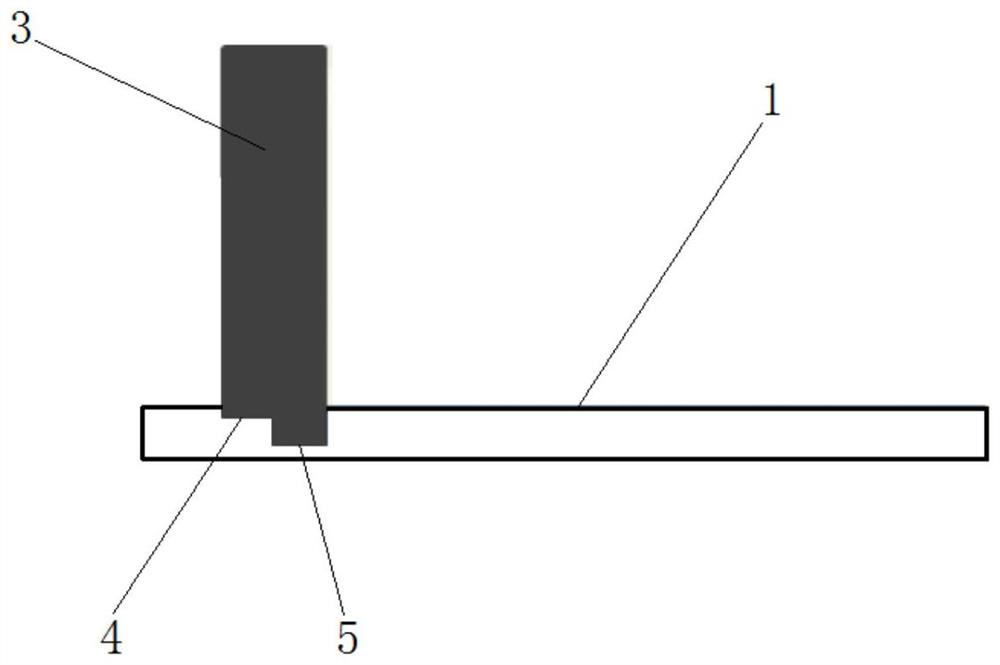

[0063] The third embodiment, such as Figure 4 As shown, the present invention is a kind of cutter head wear monitoring system that is used for Trim process cutter head wear monitoring in BSI technology, comprises:

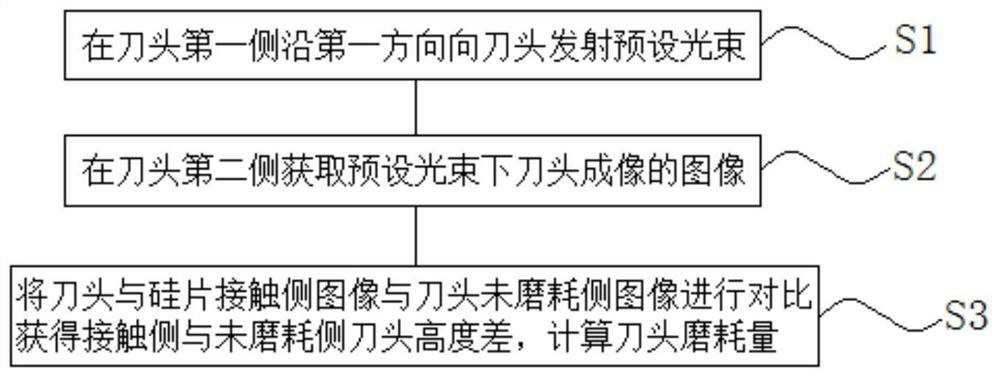

[0064] The light source 6, which is arranged on the first side of the cutter head, is used to emit a preset beam to the cutter head along the first direction;

[0065] Imaging unit 7, which is arranged on the second side of the cutter head, is used to obtain the image of the cutter head under the preset beam, and output the image of the cutter head to the processing unit; the simplest imaging unit is a backplane and a camera, The photographic equipment shoots the image of the cutter head on the back plate;

[0066] A processing unit 8, which receives the image output by the imaging unit, compares the image of the contact side of the cutter head with the silicon wafer and the image of the unworn side of the cutter head, obtains the height difference between the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com