Plywood glue spraying equipment

A plywood and glue spraying technology, which is applied in the direction of spraying devices, liquid spraying devices, etc., can solve the problems affecting the fluidity and viscosity of glue, achieve the effect of fast spraying speed, high efficiency, and prevention of glue curing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings, but the embodiments of the present invention are not limited thereto.

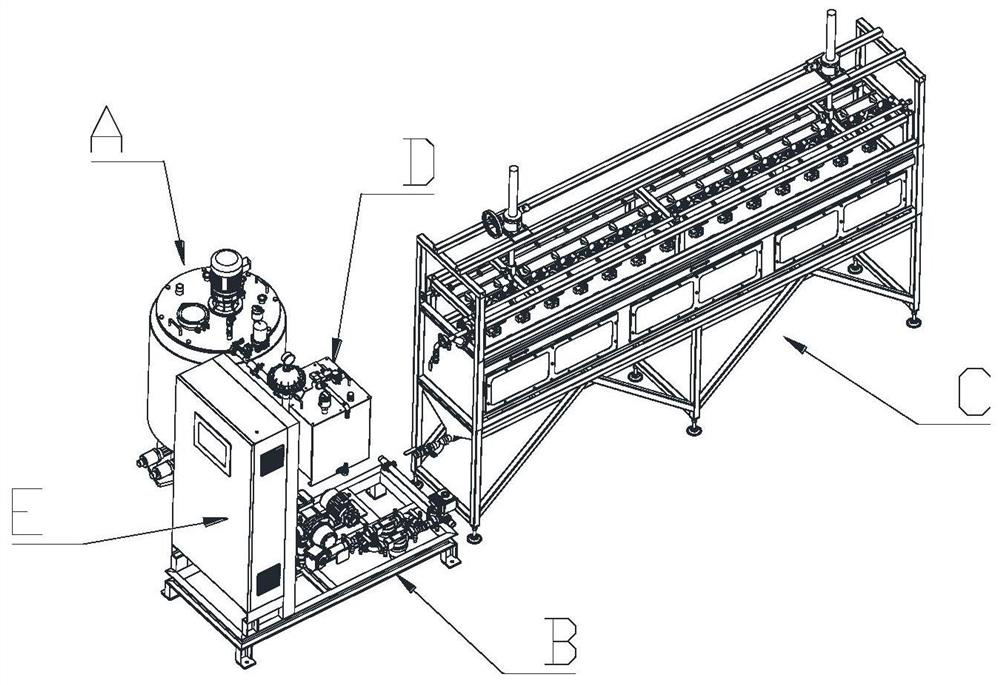

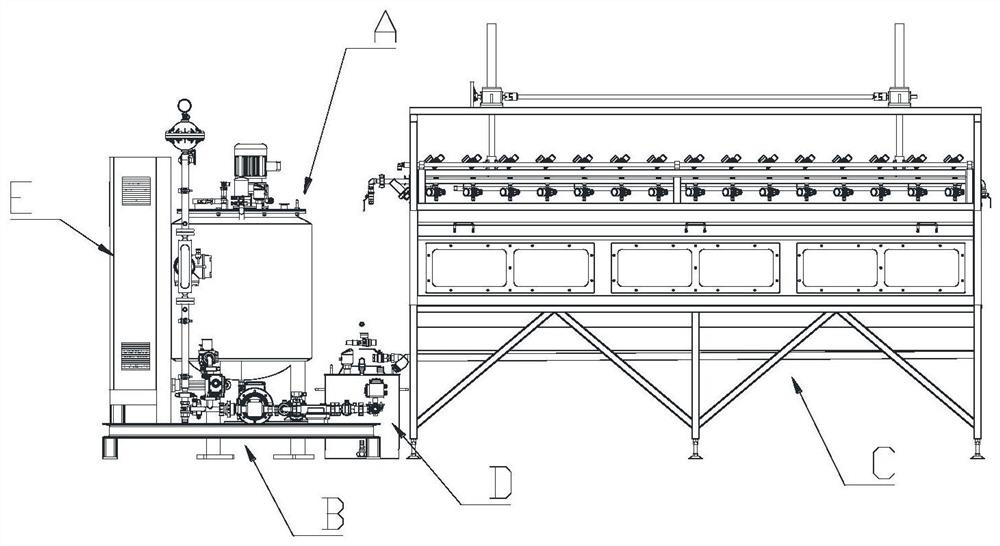

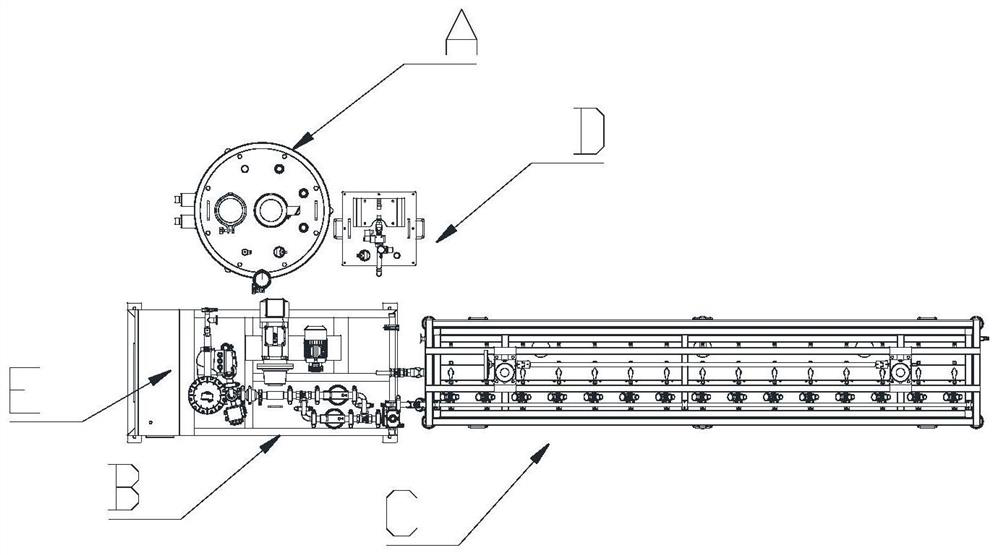

[0036] see Figure 1-Figure 13 , The plywood glue spraying equipment of the present invention includes a glue storage system A, a glue spraying system C, a glue delivery system B and an integrated control cabinet E for sending the glue in the glue storage system A to the glue spraying system C.

[0037] see Figure 1-Figure 13 , the glue storage system A includes a first frame and a glue storage tank 1 arranged on the first frame.

[0038] see Figure 1-Figure 13 , the glue spraying system C includes a second frame 47 and a glue spraying device arranged on the second frame 47, wherein the glue spraying device includes a bracket 46 arranged on the second frame 47, a bracket set on the bracket The glue spraying module on 46 and the control module for controlling the flo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com