Pneumatic cylinder group

A pneumatic cylinder and air cylinder technology, applied in the direction of fluid pressure actuation device, etc., can solve the problems of adjustment and control of the moving speed of the piston and piston rod, and the time delay of returning to the original state, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

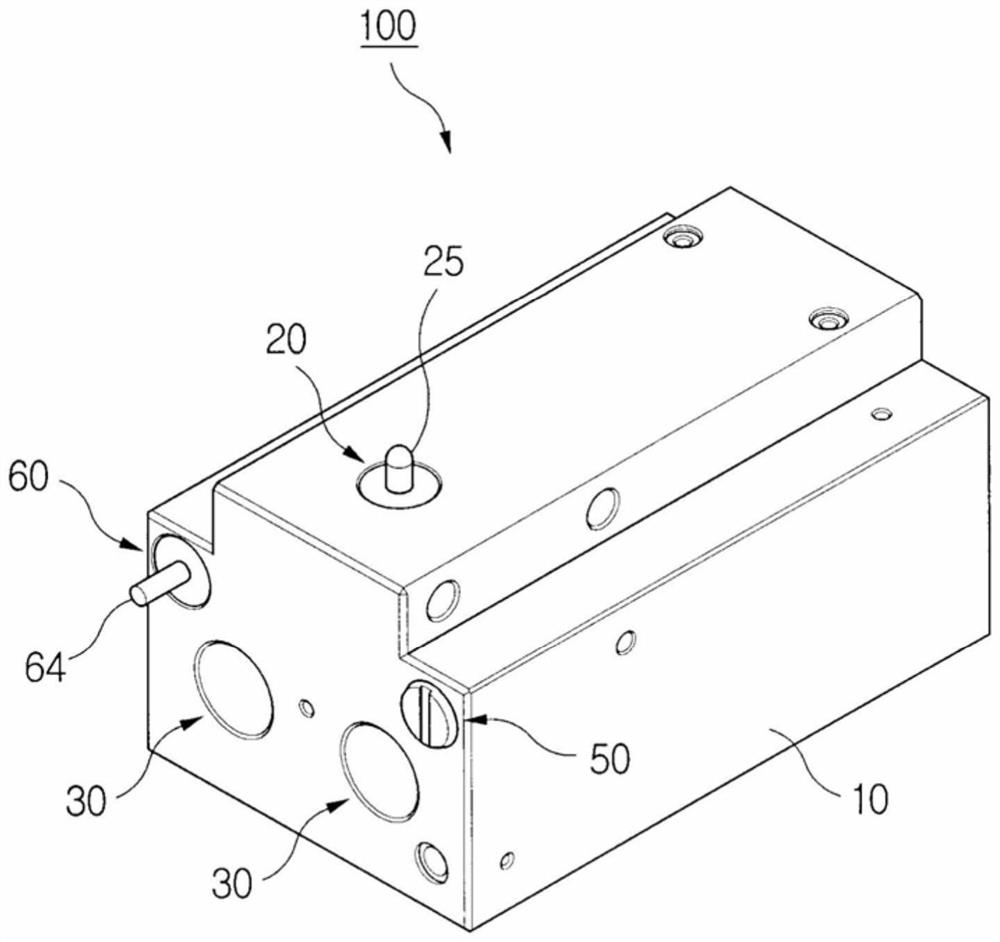

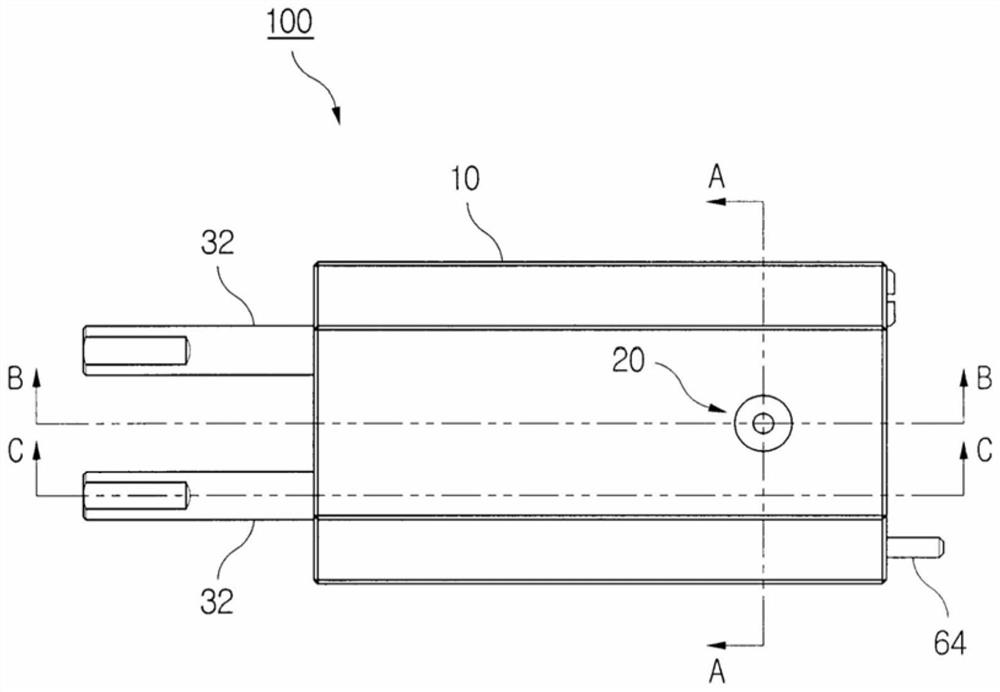

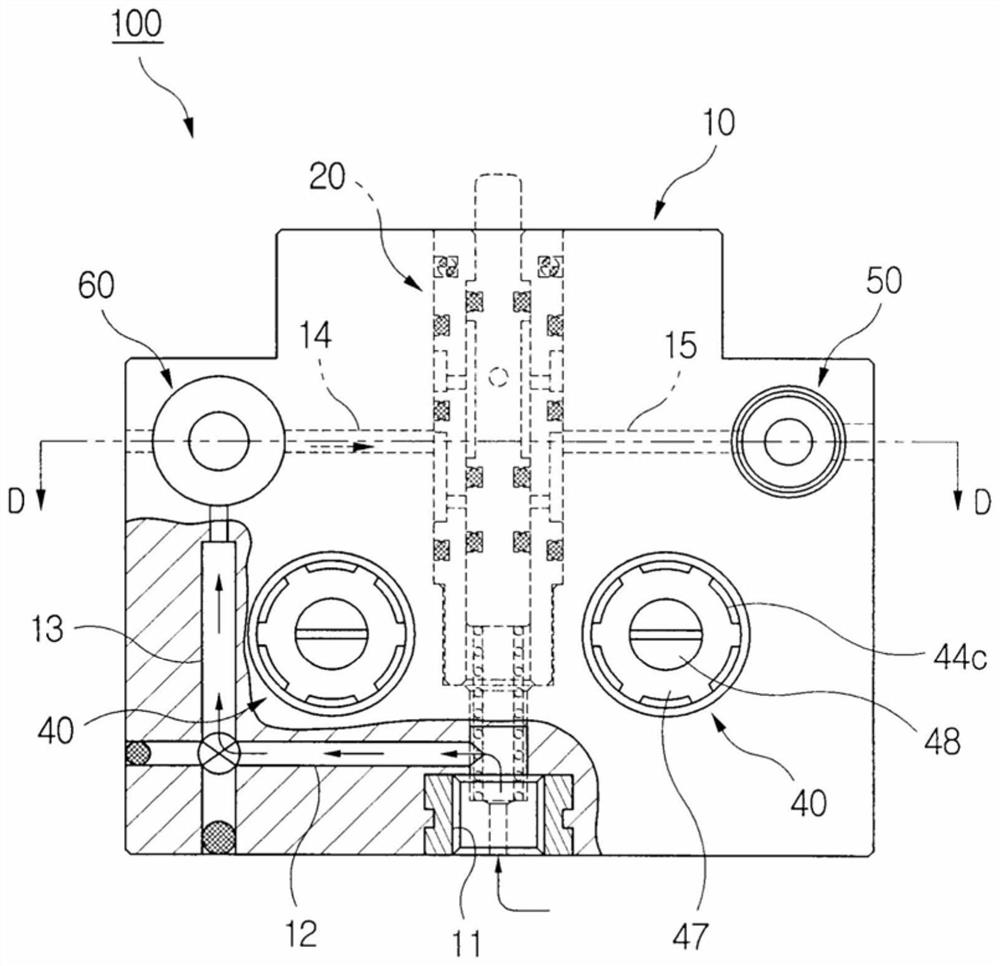

[0044] The features and effects of the "pneumatic cylinder group (hereinafter referred to as cylinder group)" of the present invention described and not described above will become more clear from the description of the embodiments described below with reference to the accompanying drawings. The cylinder bank according to the invention is identified with the symbol "100" in the individual figures.

[0045] The cylinder block 100 of the present invention includes: a reinforced plastic block-type main body 10; a compressed air injection port 11 organically formed and arranged inside the main body 10 by processing the main body 10; a control part 20; a cylinder part 30; a valve part 40; part 50; and release part 60. The injection port 11 is formed in front of the lower surface of the main body 10 . Here, the compressed air inlet 11 is configured as a single unit.

[0046] Said control part 20 comprises: a switching device 21 arranged on the main body 10 to allow the supply of c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com