Dragon type glass tank furnace

A glass pool and dragon-shaped technology, applied in glass production, furnaces, retort furnaces, etc., can solve the problems of high energy consumption, difficult to meet the requirements of international standards, unstable physical and chemical properties, etc., to achieve uniform temperature, high utilization rate, The effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

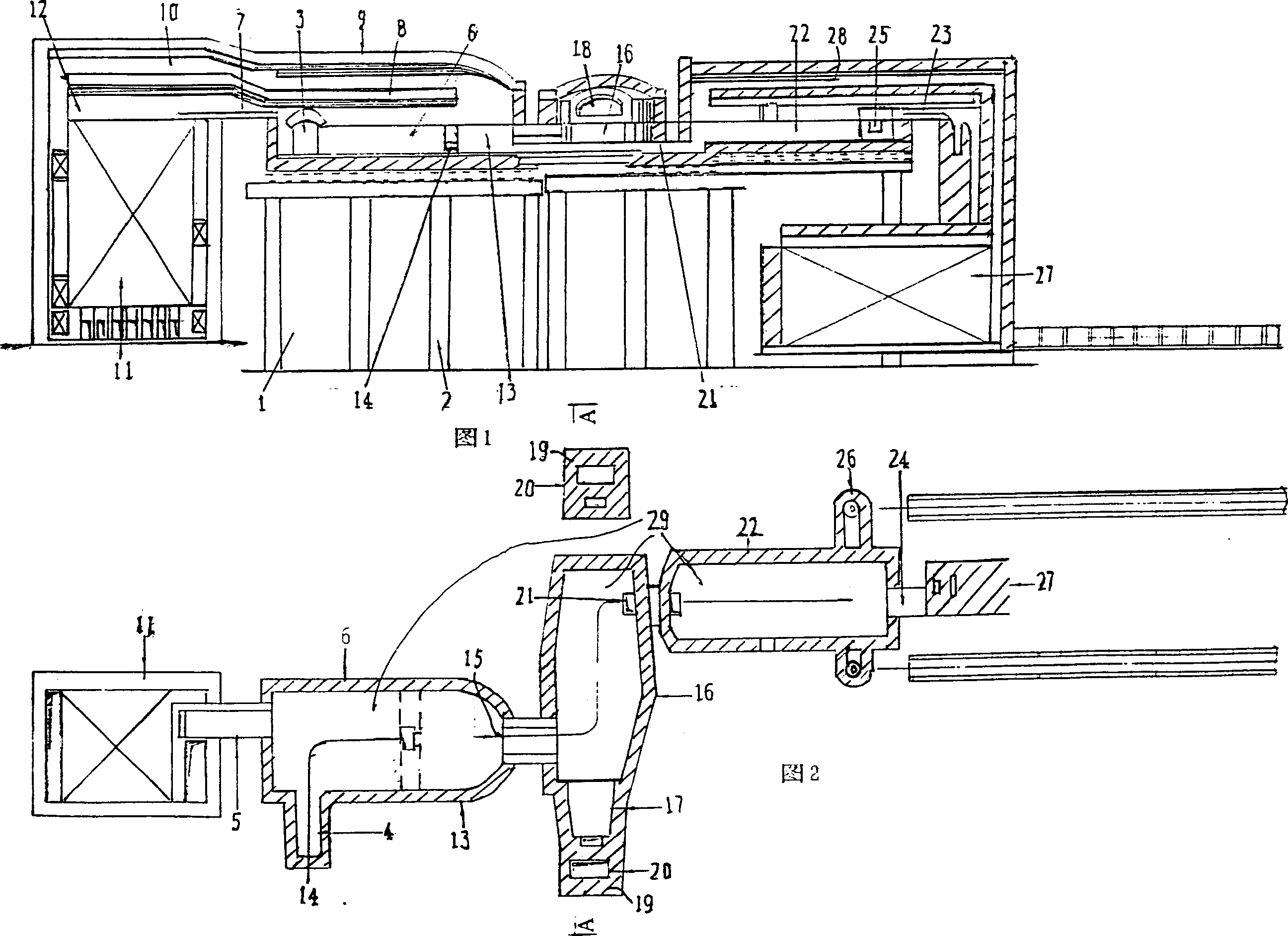

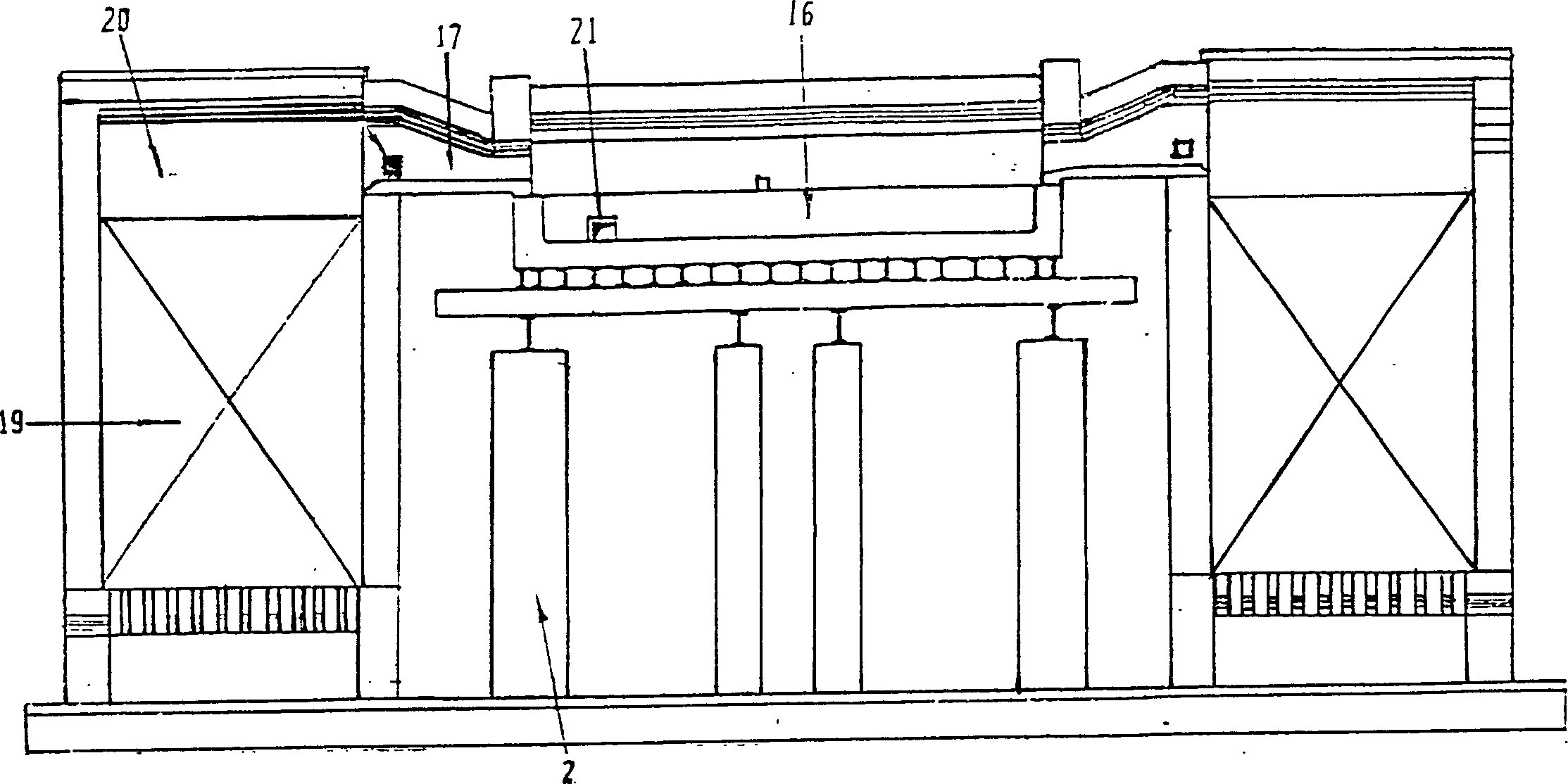

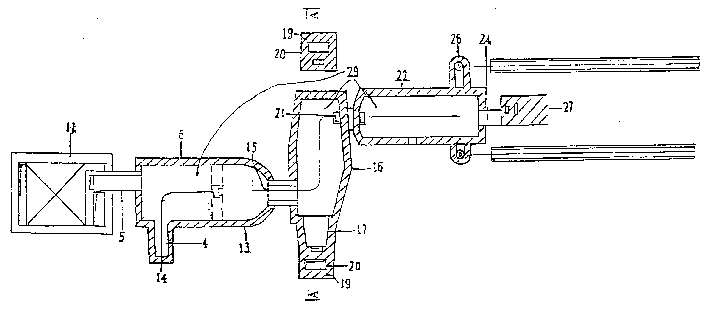

[0019] See Figure 1~ image 3 , Furnace body 1 is installed on the bracket 2. Inside the furnace body 1 is provided a premelting pool 4 with a feeding port 3 . The vertical flame melting pool 6 containing the vertical flame spout 5 communicates with the premelting pool. The vertical flame small furnace 7 communicates with the vertical flame nozzle 5 . One end extends into the furnace body and is located between the inner chord 8 of the double furnace cover and the outer chord 9 of the double furnace cover above the longitudinal flame melting pool to form a waste heat swirling channel 10 . The vertical heat exchange type exchange device 11 located in the furnace body communicates with the waste heat revolving channel and there is a hot air ascending passage 12 communicated with the longitudinal flame small furnace above it. The vertical flame clarification pool 13 communicates with the vertical flame melting pool through the liquid hole 14 at the bottom of the pool with a gen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com