Dynamic torque testing machine of crossed roller bearing for harmonic reducer

A technology of crossed roller bearings and harmonic reducers, which is applied in the direction of mechanical bearing testing, force/torque/power measuring instruments, and force sensors related to bearings. Low precision and other problems, to achieve the effect of improving the accuracy of torque batch detection, compact structure, and meeting the needs of batch testing tasks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

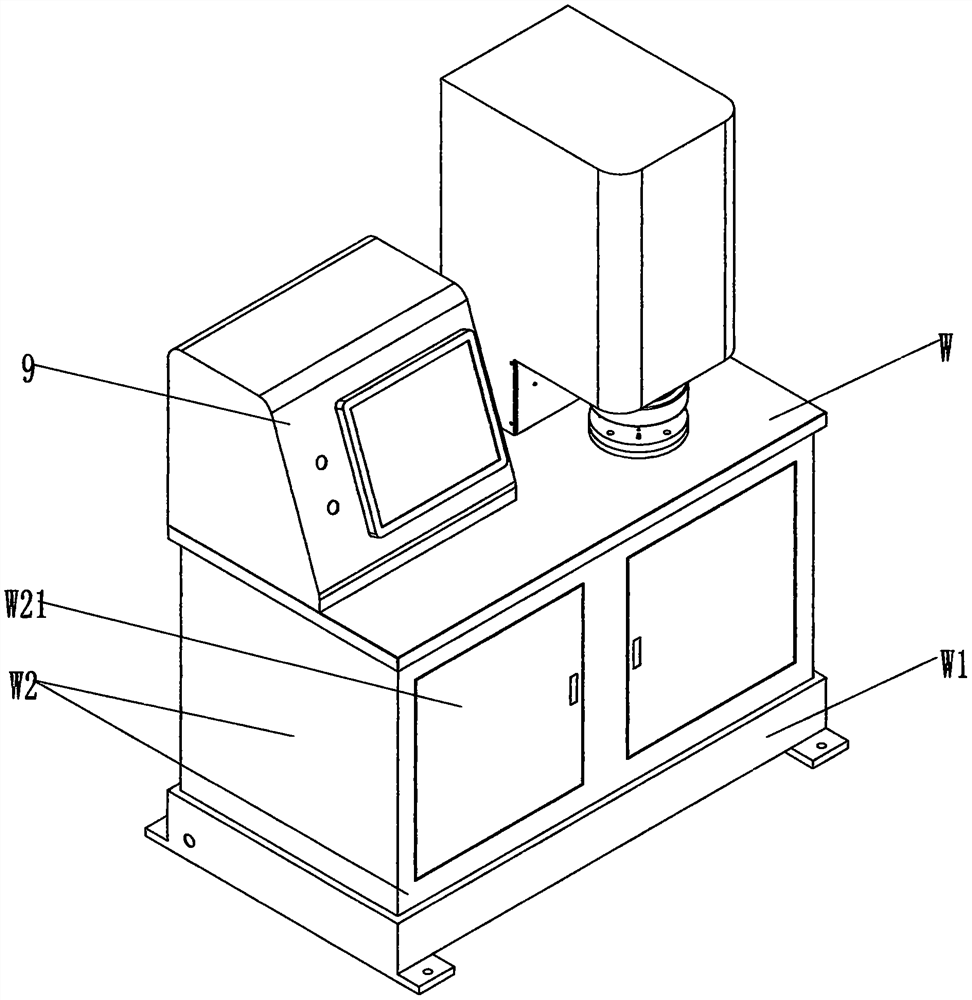

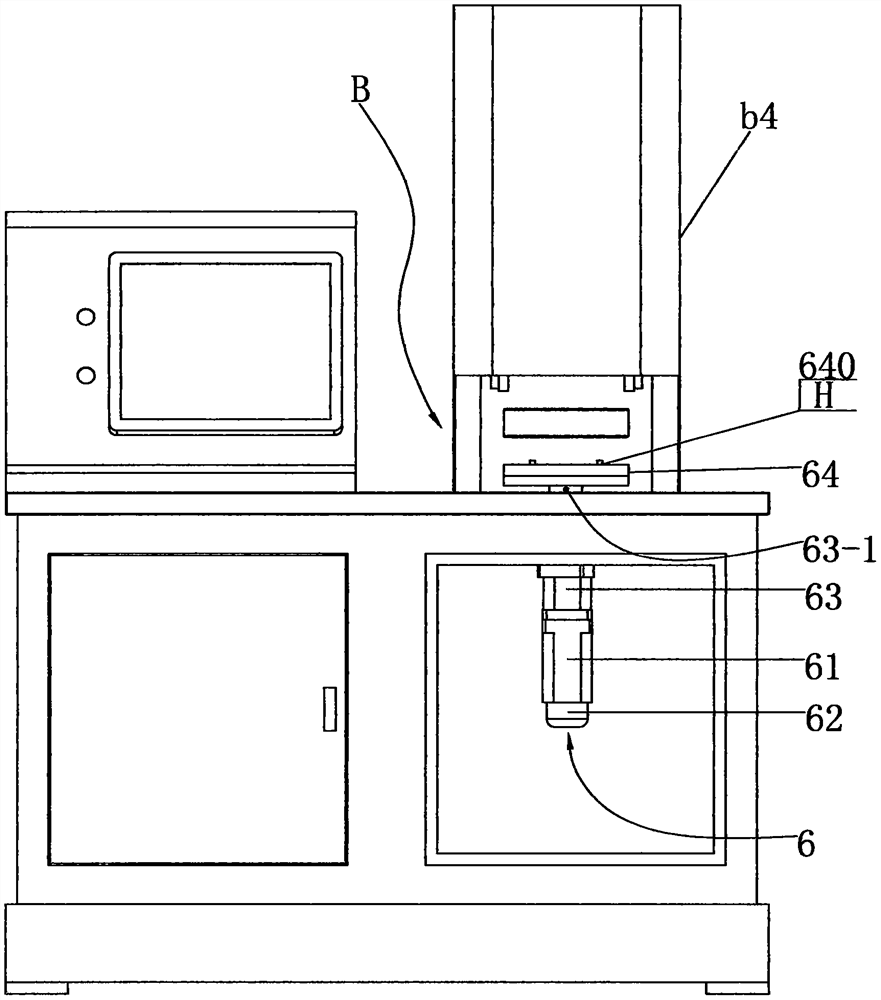

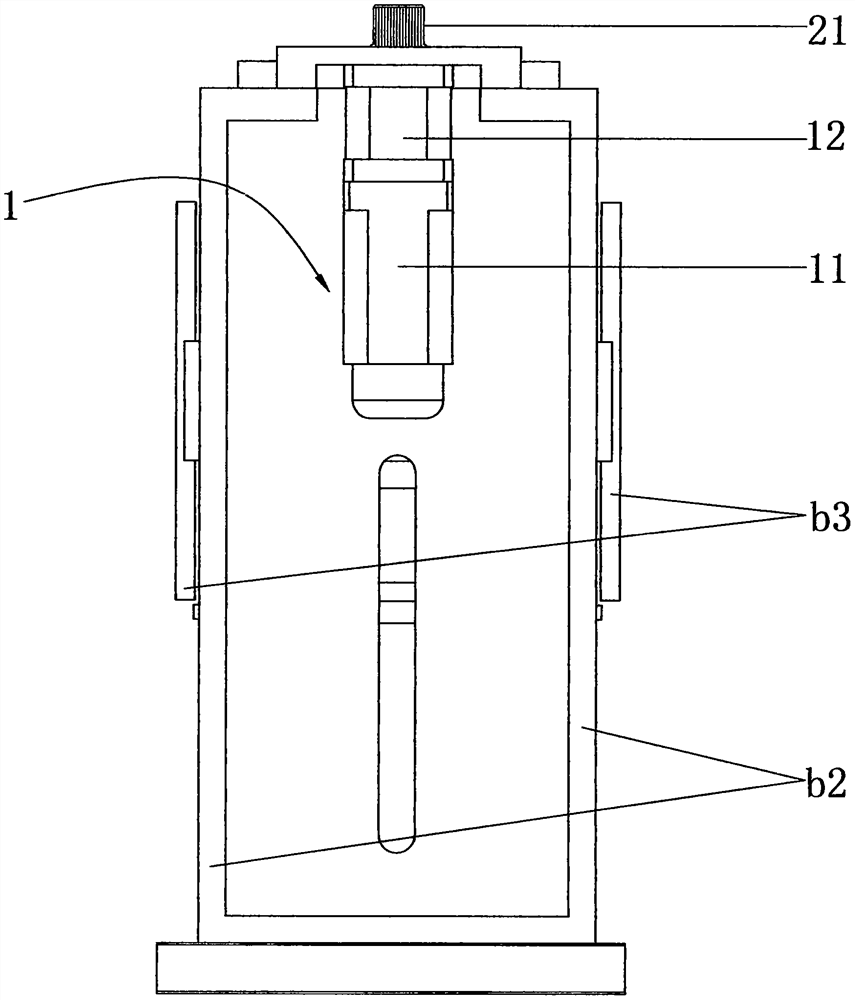

[0024] see Figure 1-7 As shown, the dynamic torque testing machine for crossed roller bearings for harmonic reducers includes workbench W, controllers 9 installed on the left and right sides of the workbench, body B, and a body cover set on body B. b4. Lifting deceleration motor, deceleration transmission mechanism, lifting mechanism, guiding mechanism, torque sensor, clamping mechanism and forward and reverse loading mechanism. Wherein, the fuselage B is mainly composed of two fuselage side panels b2 of the same shape and specifications and a fuselage roof b1 welded into a fuselage frame, and a partition (not shown) is welded between the two fuselage side panels, thereby Divide the fuselage B into a front fuselage and a rear fuselage. The outer walls of the side panels of the two fuselages respectively fix the guide rail mounting plate b3; the base W1 is set under the workbench W, and the cabinet W2 is connected between the base and the workbench. Two cabinet doors W21.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com