R-T-B series magnetic material and preparation method thereof

A technology of R-T-B and magnetic materials, applied in the direction of magnetic materials, magnetic objects, inductors/transformers/magnets, etc., can solve the problems of high cost, no significant improvement, and limited improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

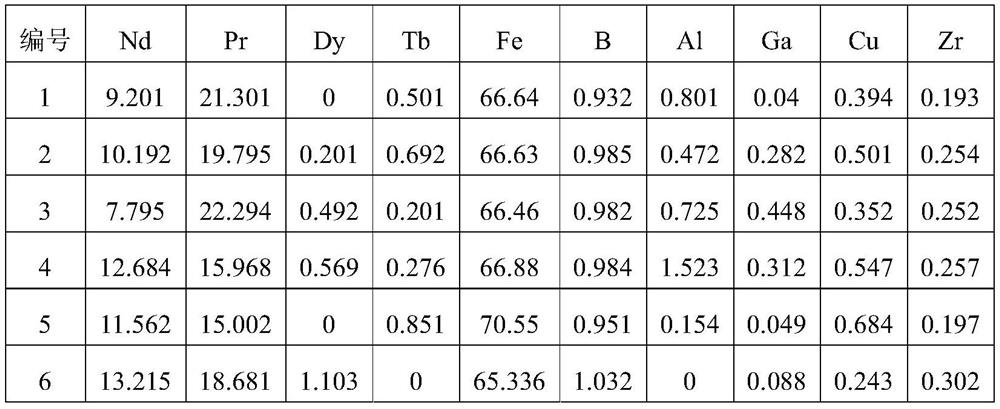

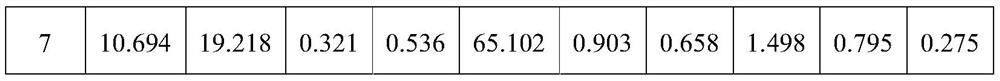

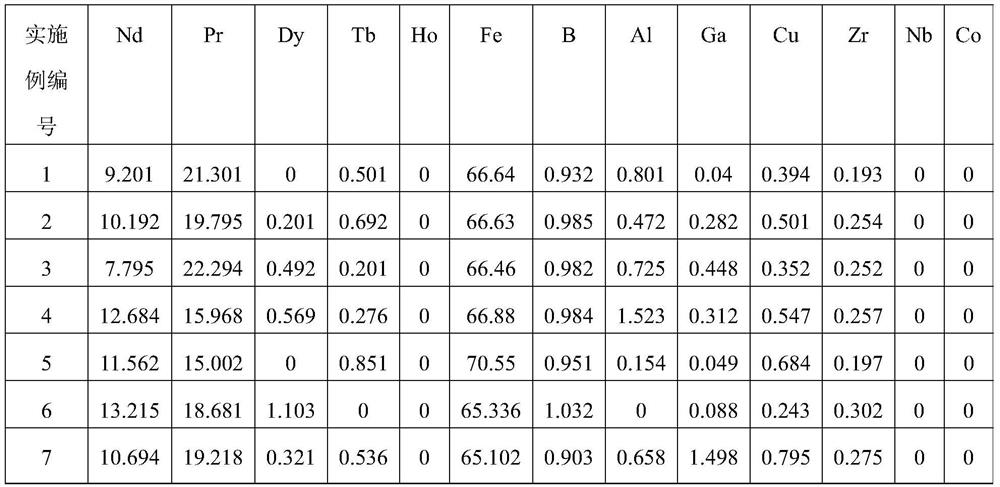

Embodiment 1

[0109] (1) Melting process: According to the formula shown in Table 1, take 50-500 kg of the prepared raw materials, put them into a crucible made of alumina, and heat them in a high-frequency vacuum induction melting furnace at 5×10 -2 Vacuum melting is carried out at 1400-1500°C in a vacuum of Pa.

[0110] (2) Casting process: after vacuum smelting, Ar gas is passed into the smelting furnace to make the air pressure reach 55,000 Pa, and then casting is carried out at 10 2 ℃ / sec-10 4 °C / sec cooling rate to obtain quenched alloy.

[0111] (3) Hydrogen crushing process: At 20-25°C, vacuumize the hydrogen crushing furnace where the quenched alloy is placed 5×10 -2 Pa, and then feed hydrogen gas with a purity of 99.9% into the hydrogen crushing furnace to maintain the hydrogen pressure at 0.15MPa. powder.

[0112] (4) Micro-grinding process: Under a nitrogen atmosphere with a content of less than 150ppm, under the condition of a crushing chamber pressure of 0.38MPa, the powde...

Embodiment 2

[0118] (1) Melting process: According to the formula shown in Table 1, take 50-500 kg of the prepared raw materials, put them into a crucible made of alumina, and heat them in a high-frequency vacuum induction melting furnace at 5×10 -2 Vacuum melting is carried out at 1400-1500°C in a vacuum of Pa.

[0119] (2) Casting process: after vacuum smelting, Ar gas is passed into the smelting furnace to make the air pressure reach 55,000 Pa, and then casting is carried out at 10 2 ℃ / sec-10 4 °C / sec cooling rate to obtain quenched alloy.

[0120] (3) Hydrogen crushing process: At 20-25°C, vacuumize the hydrogen crushing furnace where the quenched alloy is placed 5×10 -2 Pa, and then feed hydrogen gas with a purity of 99.9% into the hydrogen crushing furnace to maintain the hydrogen pressure at 0.15MPa. powder.

[0121] (4) Micro-grinding process: Under a nitrogen atmosphere with a content of less than 150ppm, under the condition of a crushing chamber pressure of 0.38MPa, the powde...

Embodiment 3

[0127] (1) Melting process: According to the formula shown in Table 1, take 50-500 kg of the prepared raw materials, put them into a crucible made of alumina, and heat them in a high-frequency vacuum induction melting furnace at 5×10 -2 Vacuum melting is carried out at 1400-1500°C in a vacuum of Pa.

[0128] (2) Casting process: after vacuum smelting, Ar gas is passed into the smelting furnace to make the air pressure reach 55,000 Pa, and then casting is carried out at 10 2 ℃ / sec-10 4 °C / sec cooling rate to obtain quenched alloy.

[0129] (3) Hydrogen crushing process: At 20-25°C, vacuumize the hydrogen crushing furnace where the quenched alloy is placed 5×10 -2 Pa, and then feed hydrogen gas with a purity of 99.9% into the hydrogen crushing furnace to maintain the hydrogen pressure at 0.15MPa. powder.

[0130] (4) Micro-grinding process: Under a nitrogen atmosphere with a content of less than 150ppm, under the condition of a crushing chamber pressure of 0.38MPa, the powde...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com