A kind of bias plate, its manufacturing method and acoustic magnetic anti-theft label made of it

A manufacturing method and technology for biasing sheets, applied in the field of biasing sheets, can solve the problems of limited use of biasing sheets, unfavorable collocation, difficulty in label demagnetization, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The alloy material (containing 8wt% Co, 20.5wt% Cr, 0.5wt% Ni, and the balance is Fe) is melted, cast ingot, hot-rolled and hot-rolled to 5mm, and the surface of the billet is ground to remove the surface oxide layer, and then Cold rolling to 0.4mm, rapid softening treatment in the single-phase zone at 850°C to prevent excessive oxidation, then direct cold rolling to 0.06mm with a 4-roll or 6-roll mill, and aging in the dual-phase zone at 540°C / 6 hours in a vacuum furnace , slit into different coils with a width of 4.5 mm, and then cut the coils into bias plates with a length of 26.5 mm to 40 mm with a high-speed shearing machine. The typical magnetic properties of the alloy bias plates are shown in Table 1 .

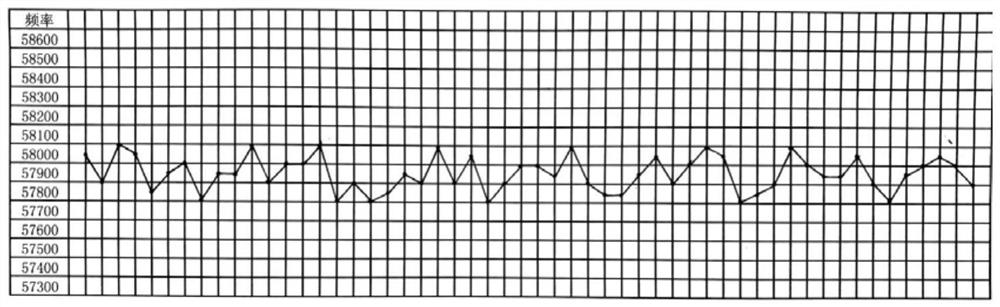

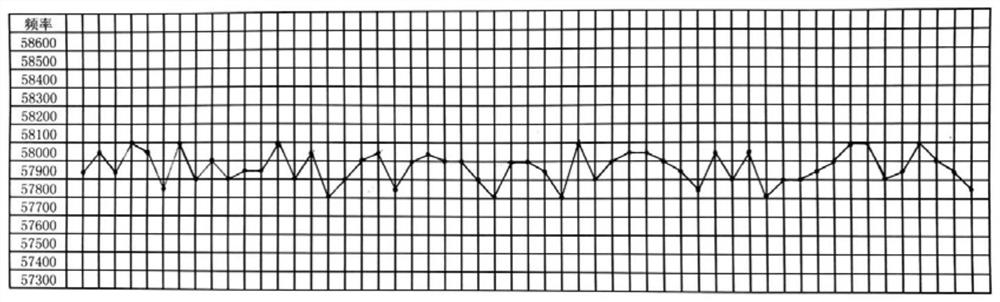

[0029] Assemble the bias sheet of this example to obtain an acoustomagnetic anti-theft tag, and perform a frequency sweep test on 108 (36 pieces*3 groups) of acoustomagnetic anti-theft tags to obtain a frequency drift table figure 1 , figure 2 shown. figure 1...

Embodiment 2

[0032] The difference between this example and Example 1 is that the alloy material (containing 8.5wt% Co, 21.5wt% Cr, 0.3wt% Cu, and the balance is Fe) was melted and cast into an ingot, hot forged, hot rolled to 5mm, Clean the surface and then cold roll to 0.4mm, 850°C single-phase zone rapid softening treatment, then use a 4-high rolling mill to press and cold-roll to 0.065mm, put it in a vacuum furnace at 580°C / 5 hours after aging in the dual-phase zone, and slit into Different coils with a width of 6 mm, and then the coils are cut into 36 mm long offset sheets with a high-speed shear. Then its magnetic properties were tested. The typical magnetic properties of the alloy bias sheet are shown in Table 1.

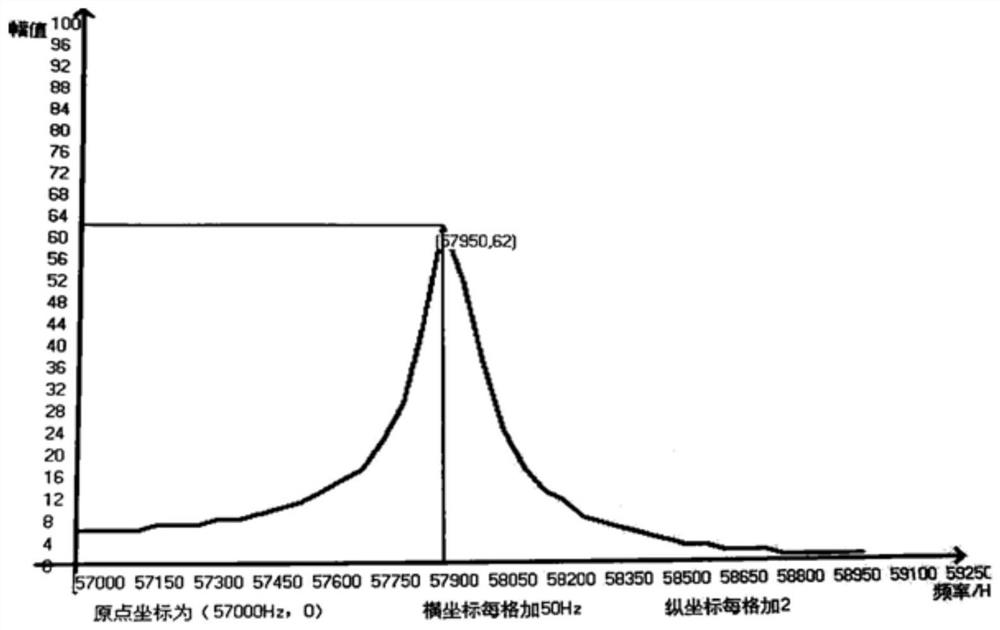

[0033] The bias sheet prepared in this embodiment is assembled to obtain an acoustomagnetic anti-theft label, and the test sample label is subjected to an amplitude test to obtain an amplitude such as image 3 shown. The acoustomagnetic anti-theft tag assembled with the...

Embodiment 3

[0035] The difference between this example and Example 1 or Example 2 is that the alloy material (containing 10.5wt% Co, 22wt% Cr, 0.5wt% Ti, and the balance is Fe) is melted and cast into an ingot, hot forged, and after smelting Ingot casting, hot forging, hot rolling to 5mm, cleared surface and then cold rolling to 0.4mm, rapid softening treatment in single-phase zone at 850°C, then direct cold rolling to 0.08mm with a 4-roll rolling mill, placed in a vacuum furnace at 605°C / 1.5 After aging in the two-phase zone for 1 hour, slitting into different coils with a width of 6 mm, and then cutting the coils into 38 mm long offset sheets with a high-speed shear. Then its magnetic properties were tested. The typical magnetic properties of the alloy bias sheet are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com