Mask forming machine

A molding machine and mask technology, applied to clothing, tools for sewing clothes, clothing, etc., can solve the problems of increasing the demand for masks, and achieve the effect of reducing the waste rate, improving production efficiency, and ensuring production quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described in conjunction with the accompanying drawings and specific embodiments.

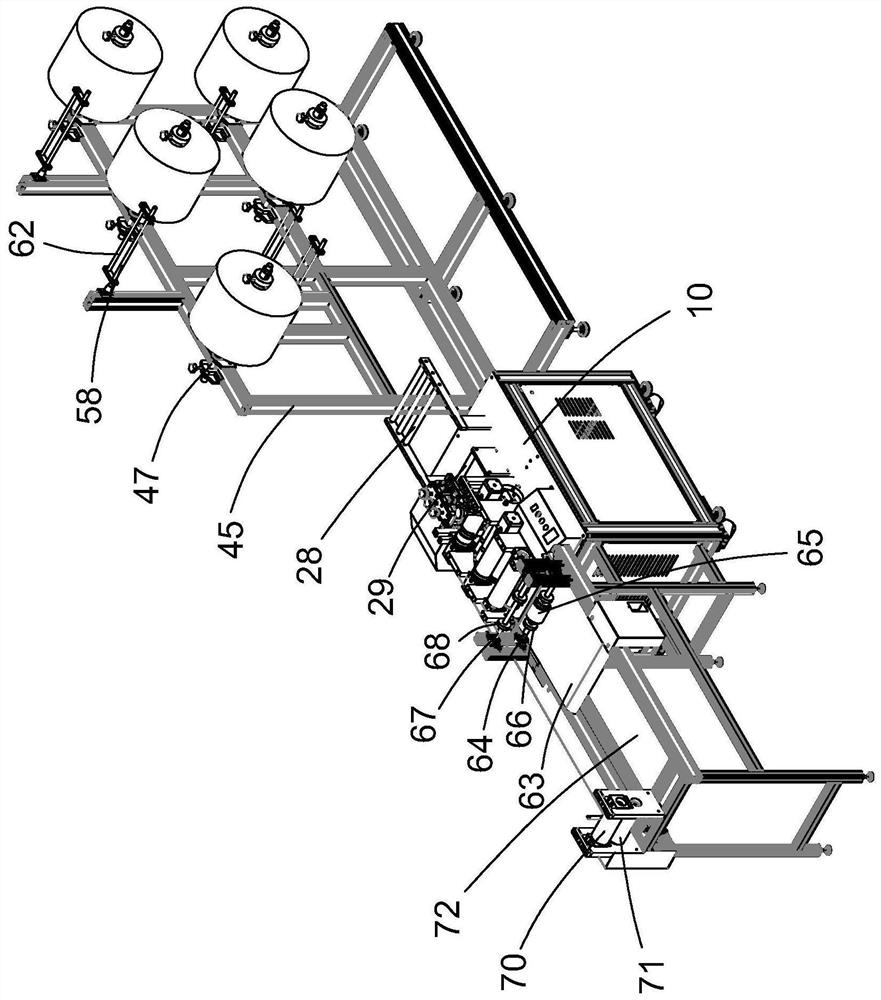

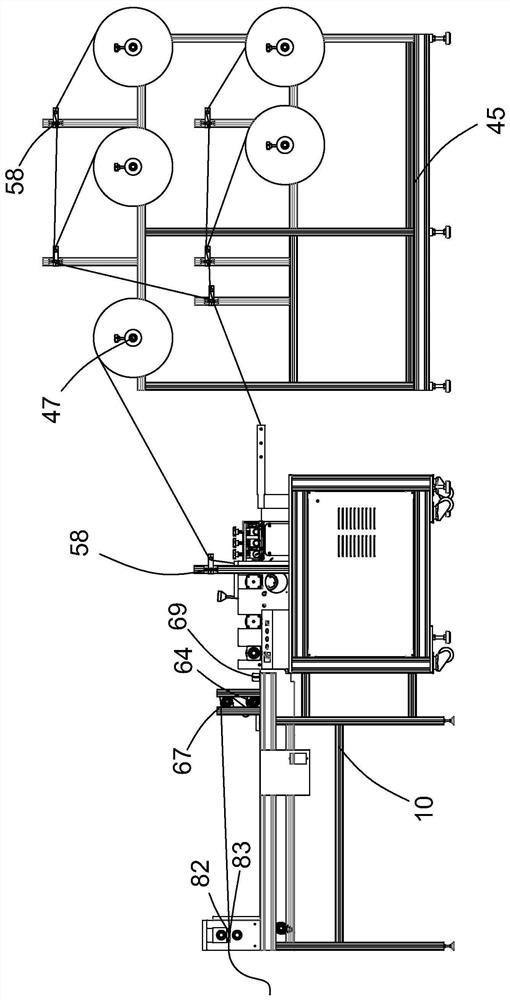

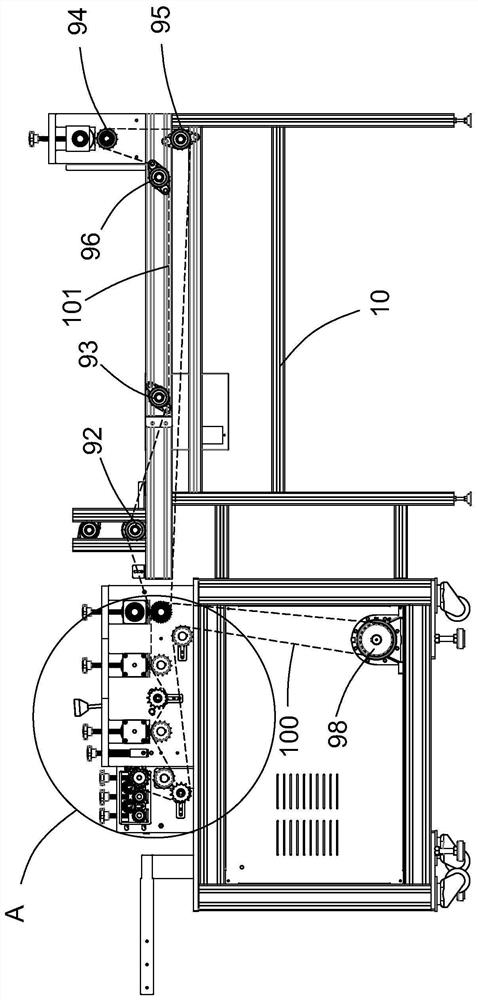

[0036] refer to Figure 1 to Figure 10 , what the embodiment of the present invention discloses is a mask forming machine, including a frame 10, and the frame 10 is sequentially provided with a pressing upper roller 11 and a lower pressing roller for merging the multi-layer mask fabric into a pattern along the processing direction 12. The upper roller 13 and the lower roller 14 for cutting the fabric into the face of the mask, the upper roller 15 and the lower roller 16 for outputting the fabric after cutting, the lower roller 12 for pressing , cutting lower roller 14, and feeding lower roller 16 are respectively rotatably arranged on the frame 10, and the pressing lower roller 12 or cutting lower roller 14 or feeding lower roller 16 are arranged before the slider There are rotating bearings that are convenient to rotate, and the upper roller 11 for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com