Solid fertilizer grinding equipment for agriculture

A solid fertilizer and agricultural technology, applied in the agricultural field, can solve the problems of affecting the grinding quality, lack of screening components, and reducing the grinding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

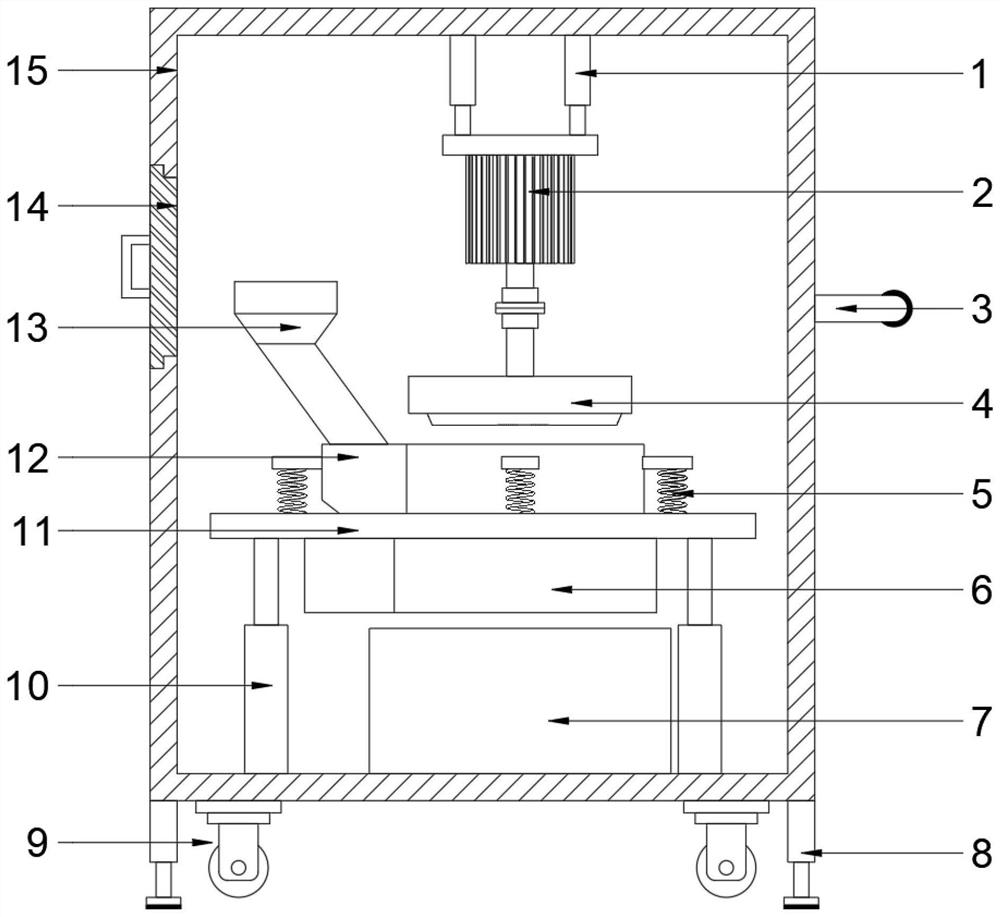

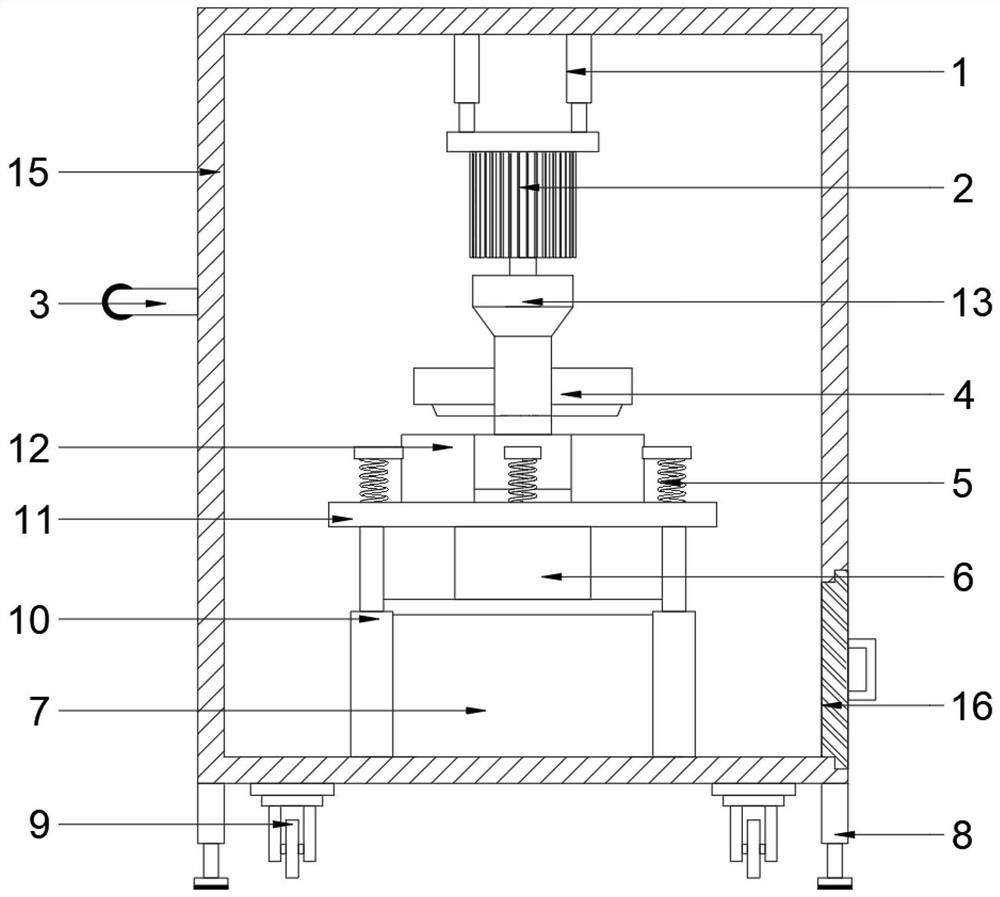

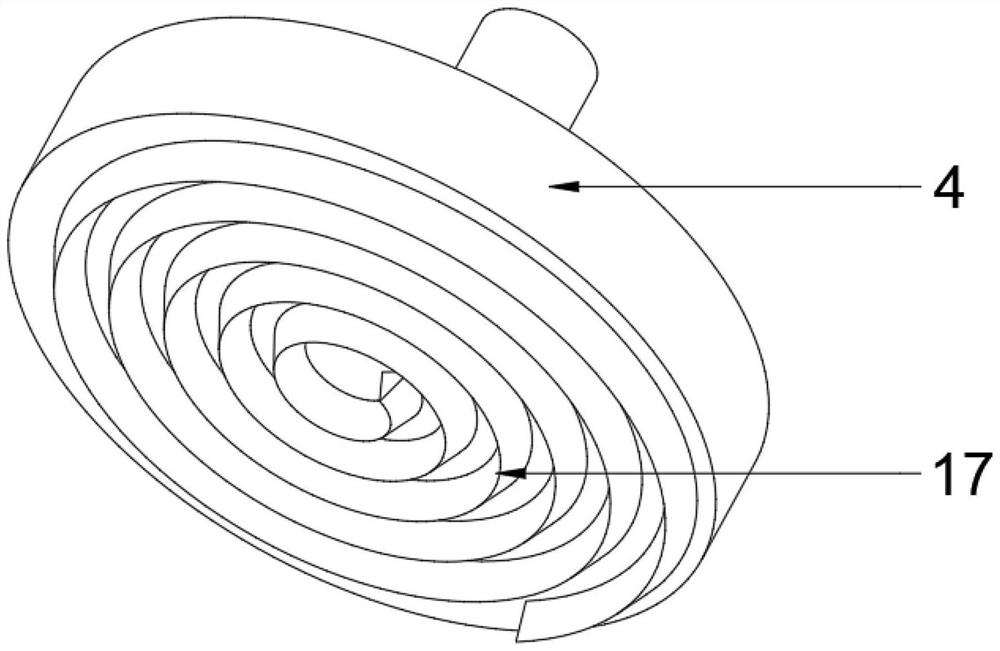

Embodiment 1

[0027] see Figure 1-6 , in an embodiment of the present invention, a kind of agricultural solid fertilizer grinding equipment includes a box body 15 and a grinding group device arranged inside the box body 15, the grinding device includes a grinding assembly and a screening assembly, and the upper end of the grinding assembly is connected to the The grinding telescopic rod 1 fixedly installed on the top of the casing 15 is fixedly connected, and the screening assembly includes a workbench 11, a screening frame 12 and a feed hopper 13, and one side of the screening frame 12 is provided with a feed groove 18 and Its bottom is provided with multiple groups of screening holes 19, and the bottom of the feed hopper 13 is fixedly installed in the feed trough 18 and its feed end corresponds to the position of the feed door 14 provided on the side wall of the casing 15, so The workbench 11 is sleeved on the periphery of the screening frame 12 and its bottom is also provided with a lif...

Embodiment 2

[0035] see figure 1 , 2, 7. In the embodiment of the present invention, an agricultural solid fertilizer grinding equipment, in order to enhance the stability and practicability of the device, the bottom of the box 15 is also provided with fixing components, the number of the fixing components is four groups and located at Near the roller 9, the fixed assembly includes a fixed telescopic rod 8 and a fixed plate 21, the upper end of the fixed telescopic rod 8 is fixedly installed on the bottom of the box body 15 and the lower end of the fixed telescopic rod 8 is fixedly provided with a fixed plate 21, and the fixed plate 21 It is used to expand the contact area between the fixed telescopic rod 8 and the ground; when working, the fixed telescopic rod 8 is extended to drive the fixed plate 21 to contact the ground, and the fixed telescopic rod 8 reversely lifts the box body 15 so that the rollers 9 is separated from the ground, stabilizes the device, and prevents the roller 9 fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com