Food sorting device

A sorting device and food technology, applied in sorting, chemical instruments and methods, cleaning methods and utensils, etc., can solve problems such as unsteady pass rate, reduce labor intensity and time of workers, increase pass rate, and improve detection efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

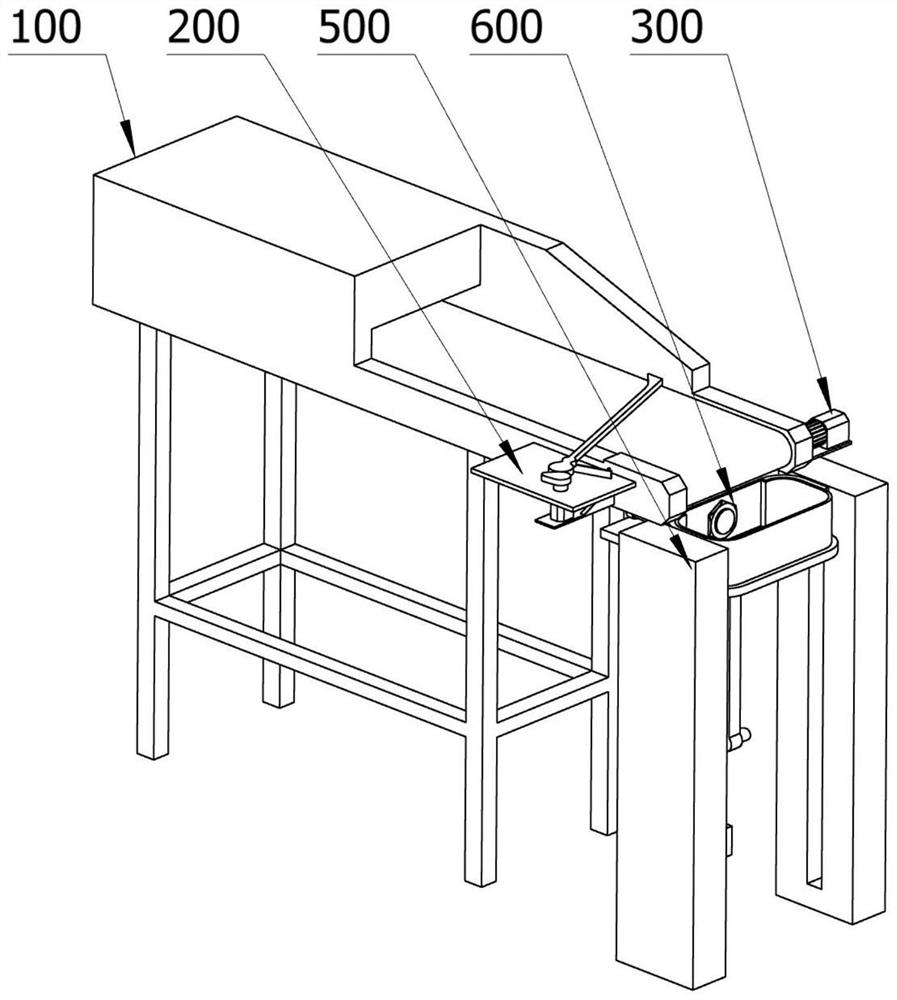

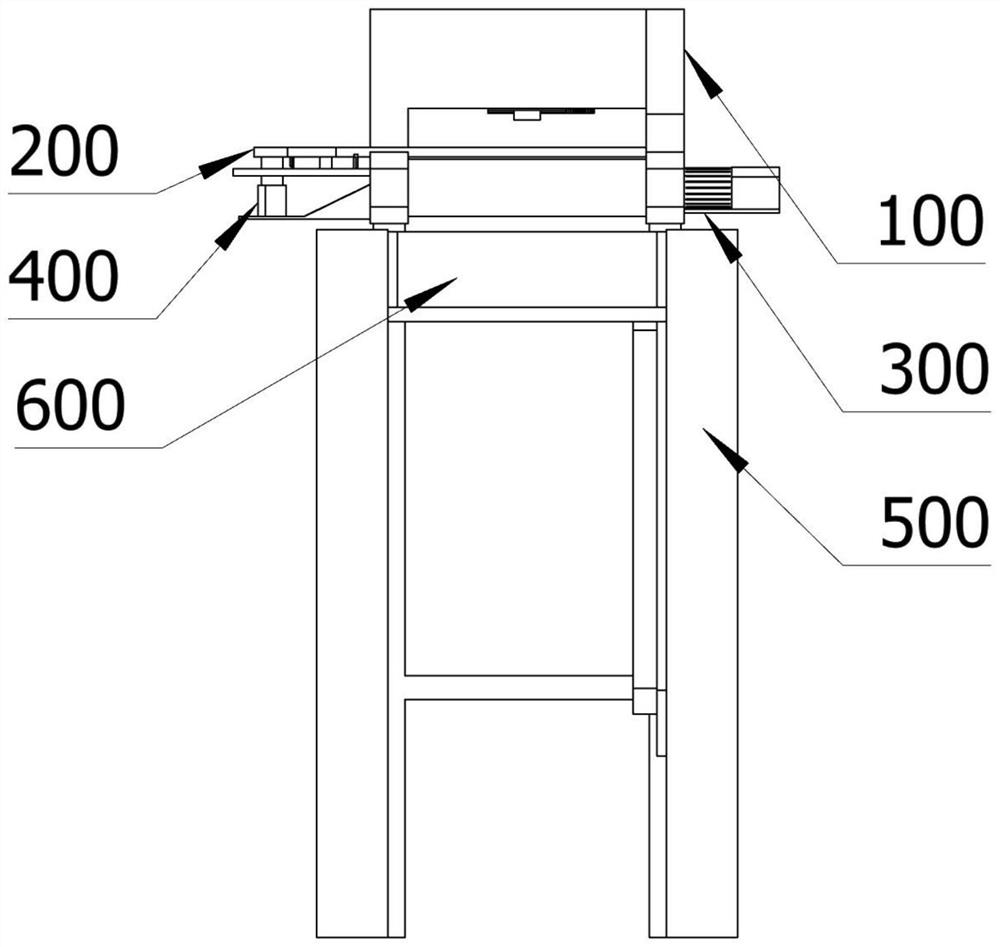

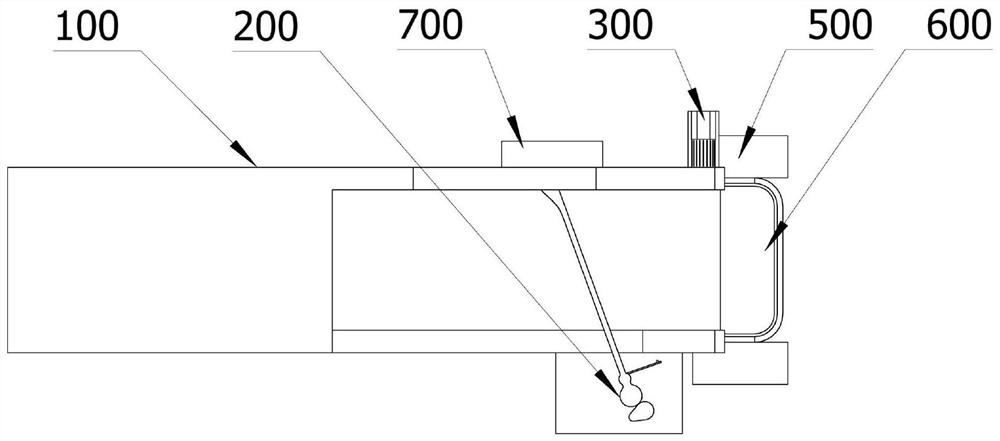

[0072] Such as figure 1 — Figure 7 As shown, a food sorting device, which includes: a first transportation part 100, a sorting part 200, a first motor 300, a second motor 400, a second transportation part 500, a blanking part 600, a lifting part 700, Mobile part 800. The first transportation unit 100 has a main body 101, the main body 101 has: a motor base 102, a conveyor belt 103, a support, a driving shaft 105, a driven shaft 106, the motor base 102 is located on one side of the main body 101, and the motor base 102 is fixed to the main body 101 Installation; the conveyor belt 103 is installed on the main body 101, and the conveyor belt 103 is used to transport food; the support member is located on the other side of the main body 101, and the support member and the main body 101 are fixedly installed; the driving shaft 105 is installed on the main body 101, and the driving shaft 105 is used is used to drive the conveyor belt 103; the driven shaft 106 is installed on the ...

Embodiment 2

[0093] A kind of food sorting method, comprises the following steps:

[0094] Feeding, after the food passes through the food production line, it evenly enters the first transportation part 100, and the first motor 300 operates to drive the driving shaft 105 to rotate, thereby driving the conveyor belt 103 for transportation, so that the food moves on the conveyor belt 103, The light source 1102 irradiates the transparent member 1105 and is reflected by the reflector 1101, so that the moving cylinder 1112 collects the information of the food entering the first transportation unit 100;

[0095] Sorting, the sorting unit 200 sorts and rejects unqualified food, thereby completing the operation process of automatic sorting;

[0096] Transportation, the food that passes the test continues to be transported through the conveyor belt 103, and when it is transported to the front of the conveyor belt 103, it will fall to the unloading part 600 due to the influence of gravity;

[0097]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com