Cutting equipment convenient to operate

一种切割设备、操作方便的技术,应用在剪床设备、金属加工设备、剪切装置等方向,能够解决切割片晃动大、固定不便、操作不便等问题,达到切割尺寸精度高、不容易碎裂、夹持牢固的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to enable those skilled in the art to better understand the solutions of the present invention, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention. Obviously, the described embodiments are only It is a part of embodiments of the present invention, but not all embodiments. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without making creative efforts shall fall within the protection scope of the present invention.

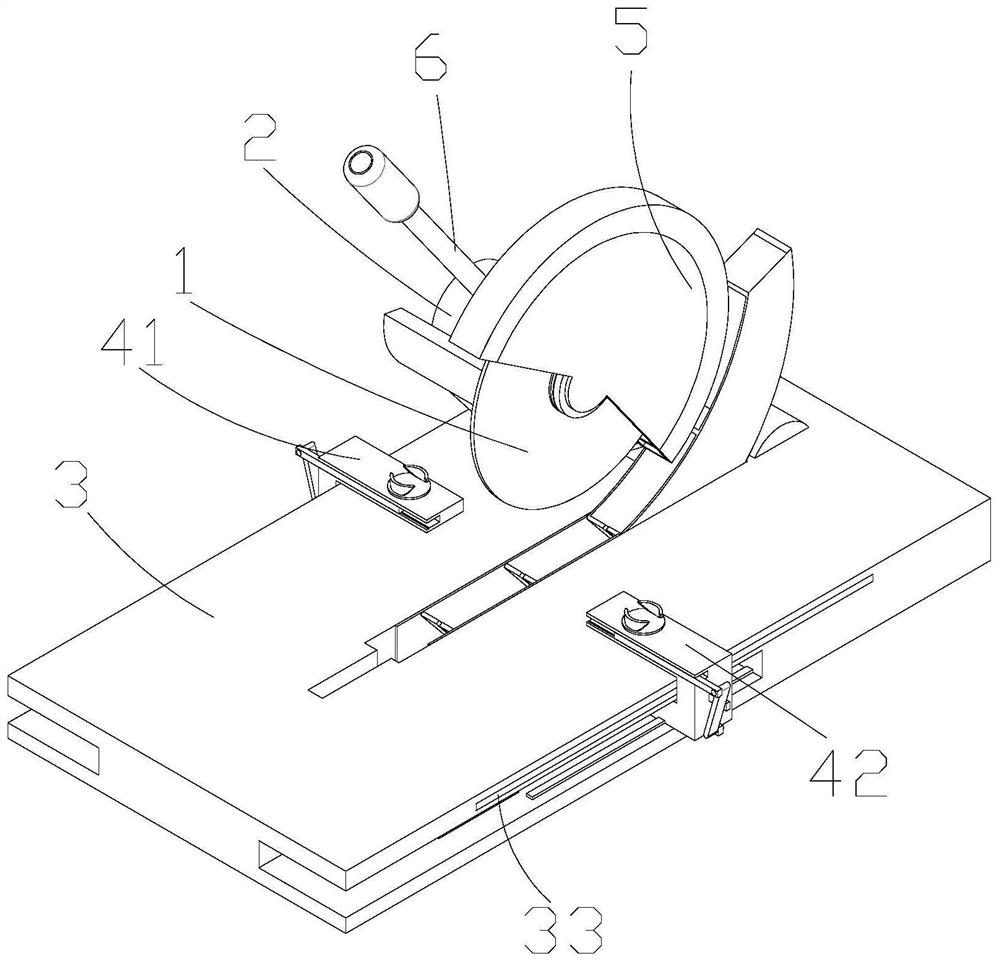

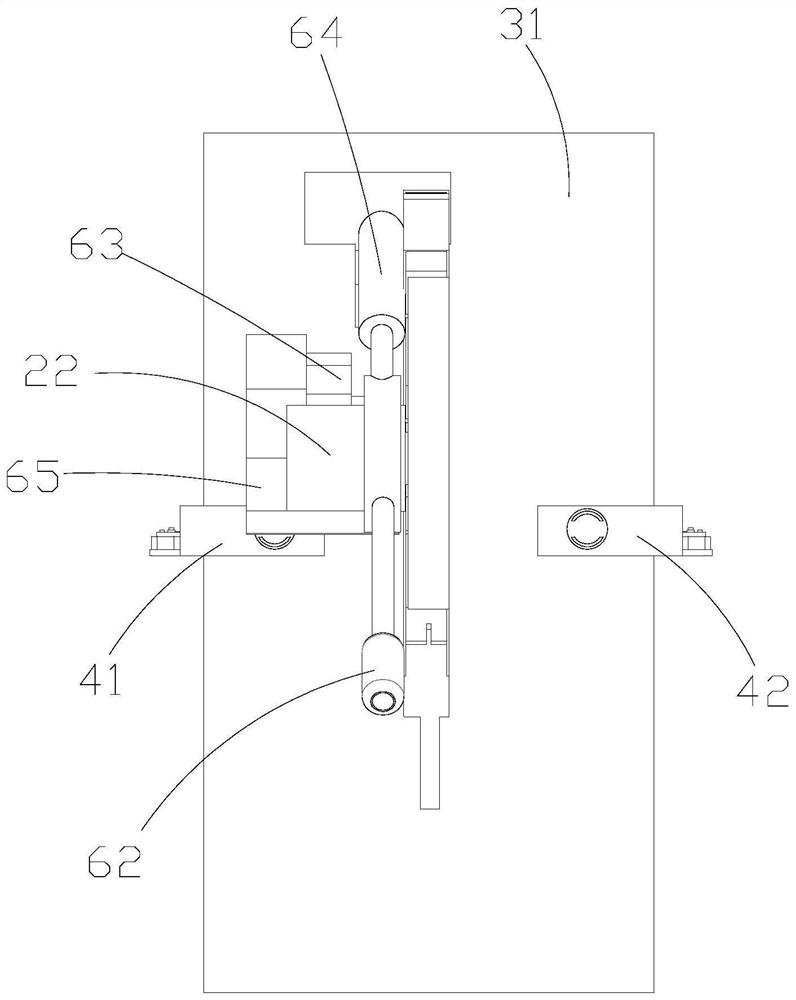

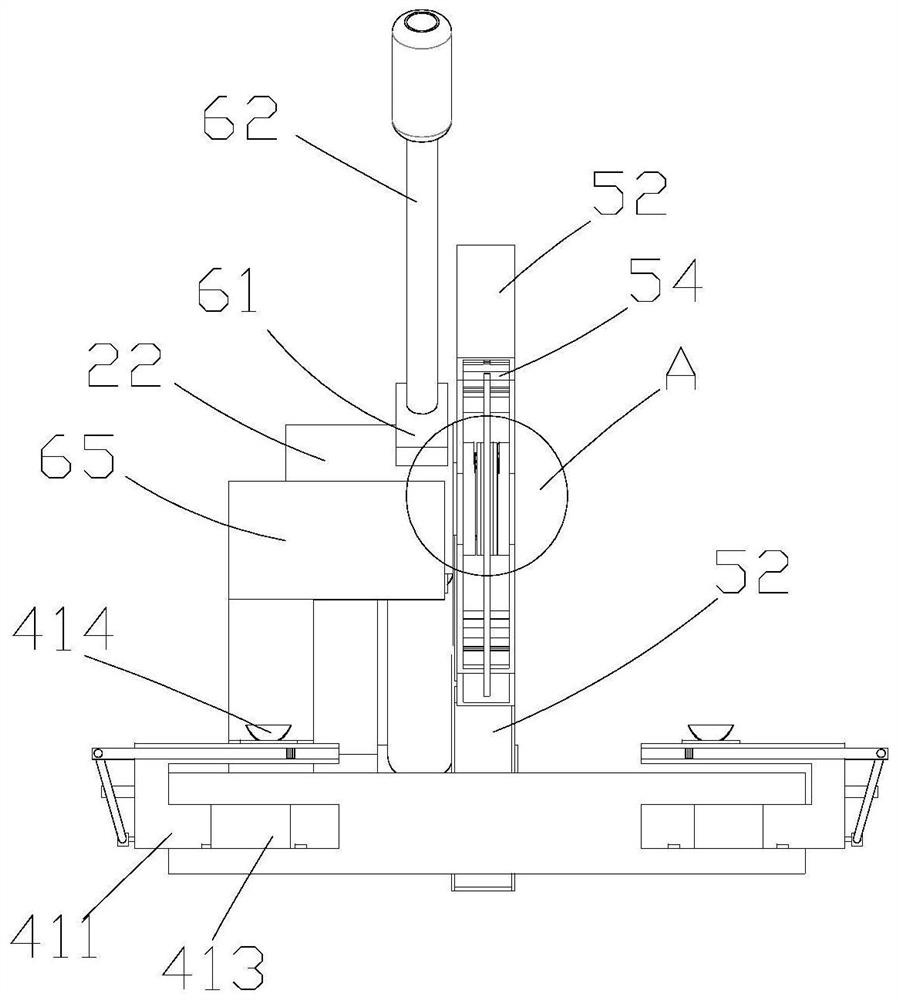

[0023] Such as Figure 1-10 As shown, a cutting device with easy operation is characterized in that it includes a cutting blade 1, a driving part 2 for driving the cutting blade to rotate, a cutting table 3, a clamping device 4 arranged on the cutting table, and a dust-proof device after cutting. Functional dust-proof device 5, a pressin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com