Efficient stirring equipment for building materials

A technology for mixing equipment and building materials, which is applied in the direction of mixer accessories, dissolvers, mixers, etc., which can solve the problems of low work efficiency, slow stirring speed, and easy agglomeration, so as to improve the mixing effect, facilitate material receiving and processing, and avoid leakage. The effect of material clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

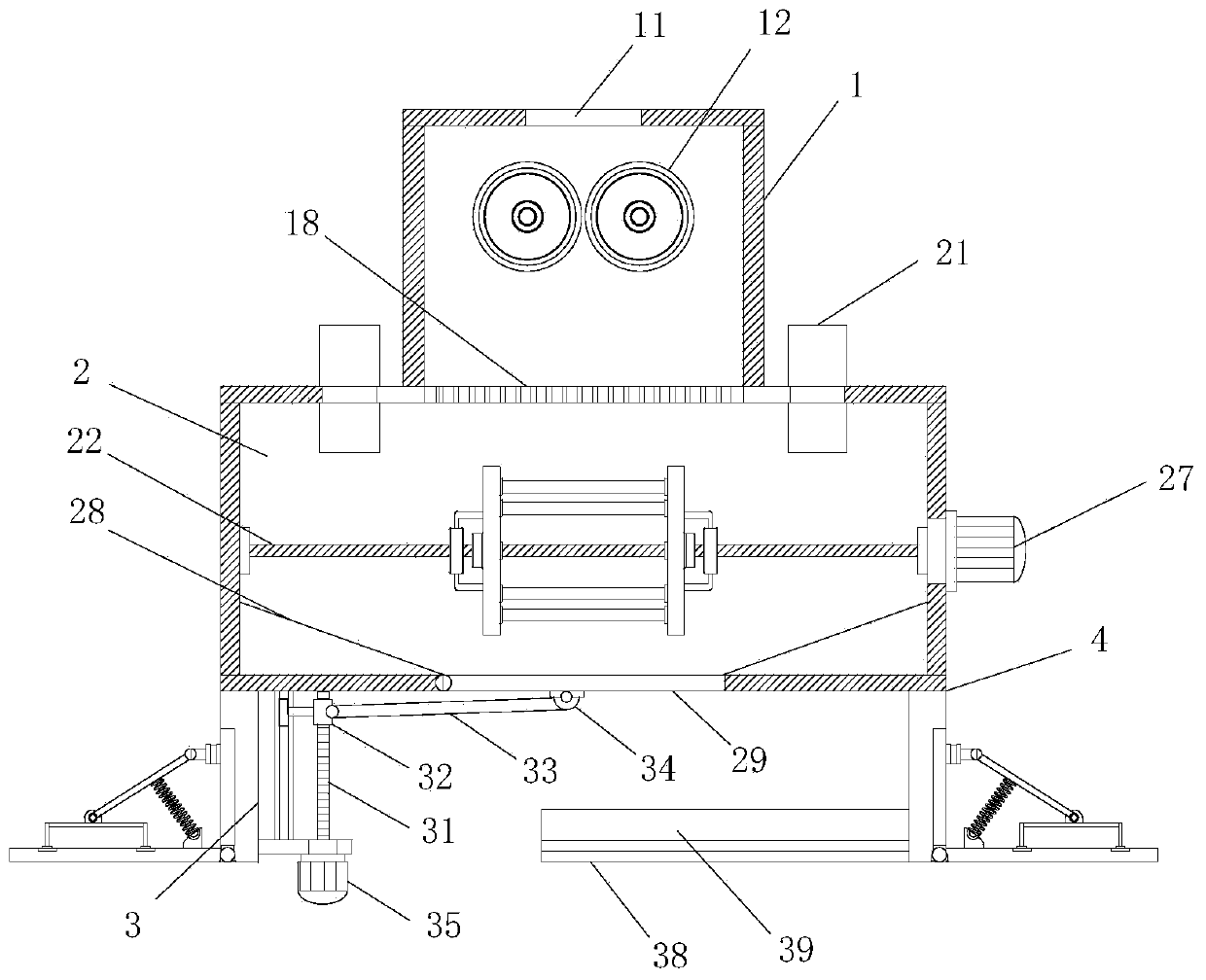

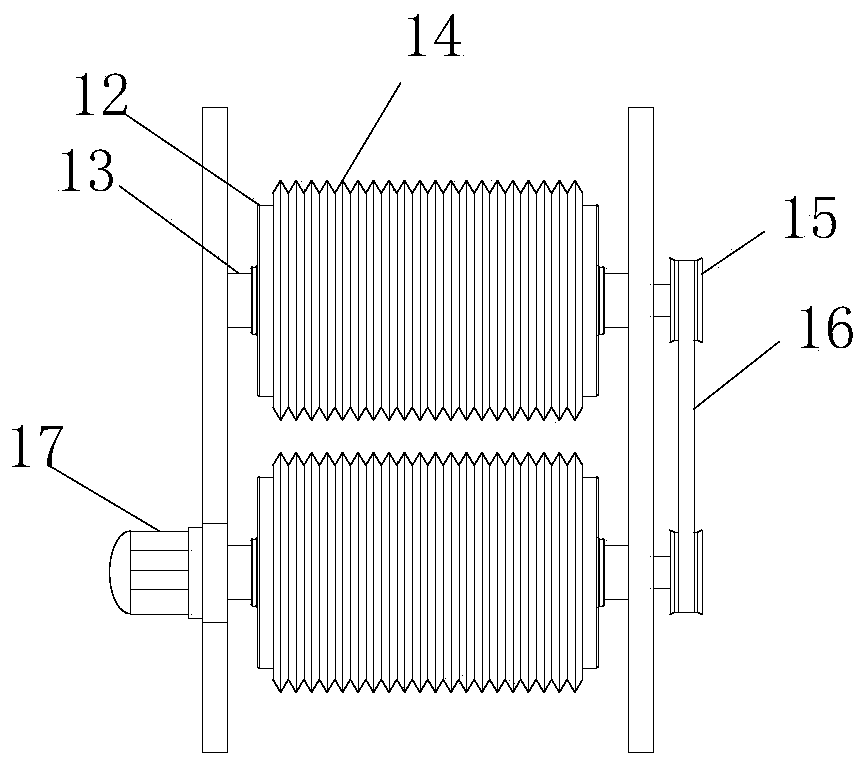

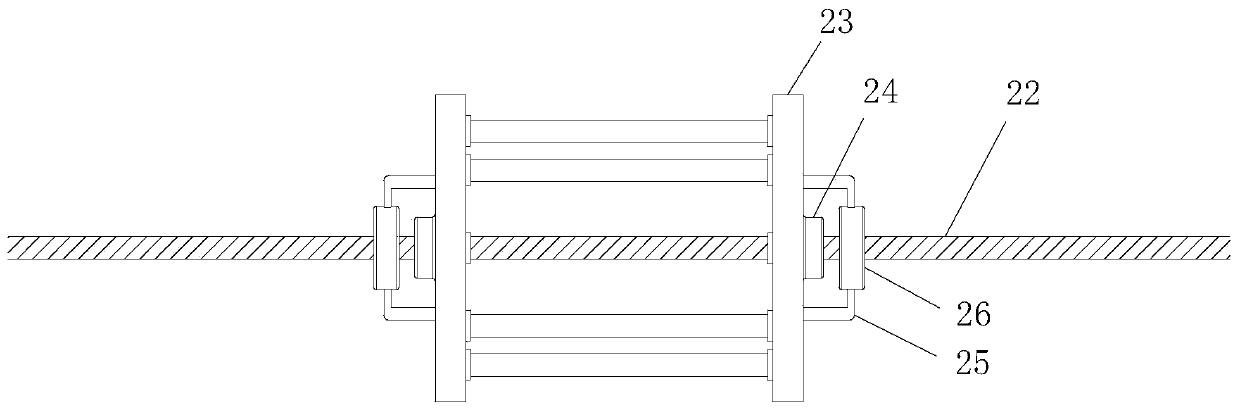

[0031] see figure 1 and figure 2 , a high-efficiency mixing equipment for building materials, including a frame 4, the frame 4 is respectively provided with a feeding chamber 1 and a stirring chamber 2, the feeding chamber 1 is arranged on the top of the stirring chamber 2, and the feeding chamber The top plate of the cavity 1 is provided with a material inlet 11, and the material inlet 11 is equipped with a crushing roller 12, and the crushing rollers 12 are provided with two paths and are arranged in opposite directions. In the crushing roller 12, the roller surface of the crushing roller 12 is provided with relatively arranged crushing teeth 14, and the roller shaft 13 is externally connected with a transmission shaft through a connecting bush, and a transmission shaft is installed on the transmission shaft. Wheel 15 is connected by belt 16 between the drive wheels 15 on both sides. A pulverizing motor 17 is installed on the side of the feeding chamber 1 , and one of the...

Embodiment 2

[0039] see figure 1 and Figure 4 , this embodiment is further optimized as Embodiment 1. On the basis of it, both sides of the frame 4 are provided with support frames 49, and the inner ends of the support frames 49 are equipped with side wing support plates 41 through steering pins 42, A fixed frame 43 is installed on the bottom plate of the support frame 49, and a reinforcing strut 46 is installed on the fixed frame 43 through a connecting bolt 44. For fixed installation, a positioning block 47 is installed on the bottom of the frame 4 , and a buffer spring 48 is arranged between the positioning block 47 and the reinforcing pole 46 .

[0040] In order to improve the stability of the overall operation, the application is equipped with support frames 49 on both sides of the frame 4, and a triangular fixed support structure is formed between the reinforced poles 46, the frame 4 and the ground substrate, and the overall stability is higher. , The reinforcing strut 46 is provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com