Large concrete unloading and stirring platform for building construction

A technology for building construction and concrete, which is applied in cement mixing devices, batching storage, clay preparation devices, etc. It can solve the problems affecting the use of equipment, the inability to realize continuous mixing of equipment, continuous feeding of concrete, etc., and achieve convenient unloading and processing, Realize the effect of continuous work and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

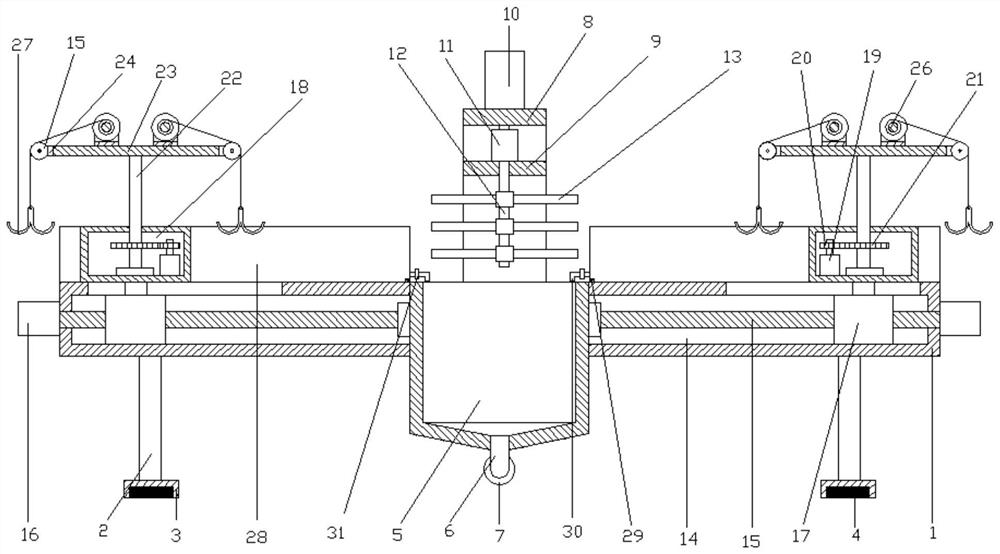

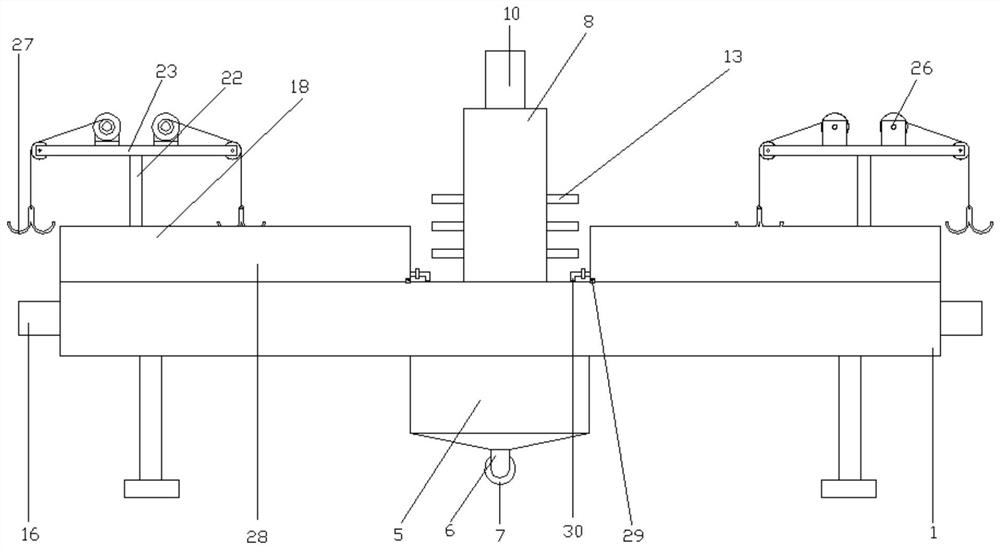

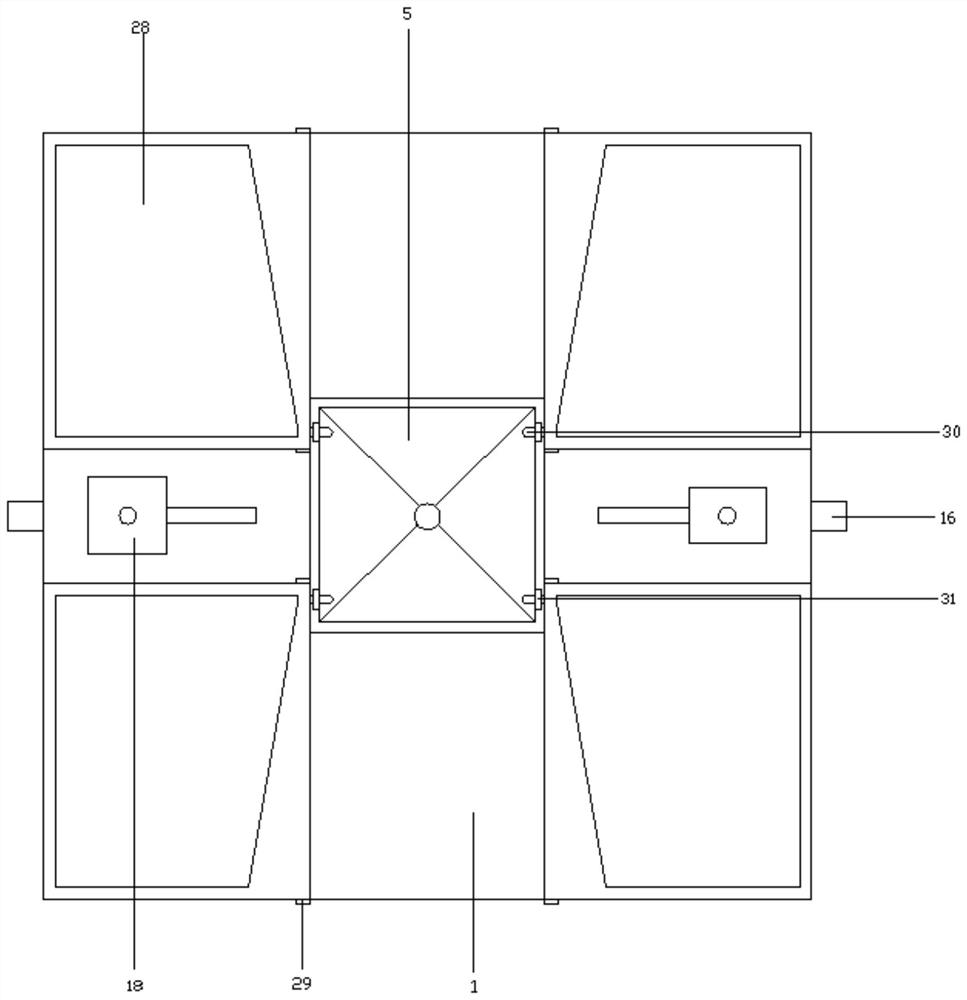

[0027] refer to Figure 1~5 , in an embodiment of the present invention, a large-scale concrete unloading and mixing platform for building construction includes a bearing platform 1, the four corners of the lower side of the bearing platform 1 are fixedly equipped with supporting legs 2, and the lower side of the supporting legs 2 is provided with a supporting block 3, which can Effectively supporting the entire equipment, the middle part of the carrying platform 1 is inlaid with a mixing chamber 5, and the lower side of the mixing chamber 5 is provided with a suction pipe 6, and a suction pump 7 is installed on the suction pipe 6, which can facilitate the discharge of prepared concrete.

[0028] The upper side of the mixing chamber 5 is provided with a mounting frame 8, and the mounting frame 8 is fixedly installed on the upper side of the bearing platform 1. The inside of the mounting frame 8 is provided with a moving plate 9, and the upper side, front and rear ends of the mo...

Embodiment 2

[0033] The difference from the first embodiment is that the bottom of the support block 3 is inlaid with a friction pad 4, which can increase the friction between the support block and the ground, so as to ensure the stability of the equipment and facilitate the use of the equipment.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap