Ultrahigh-pressure stone water jet cutting machine

A cutting machine, stone water technology, applied in stone processing tools, stone processing equipment, metal processing, etc., can solve the problems of sludge not being cleaned together in time, heat cooling range is small, and cleaning efficiency is reduced

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

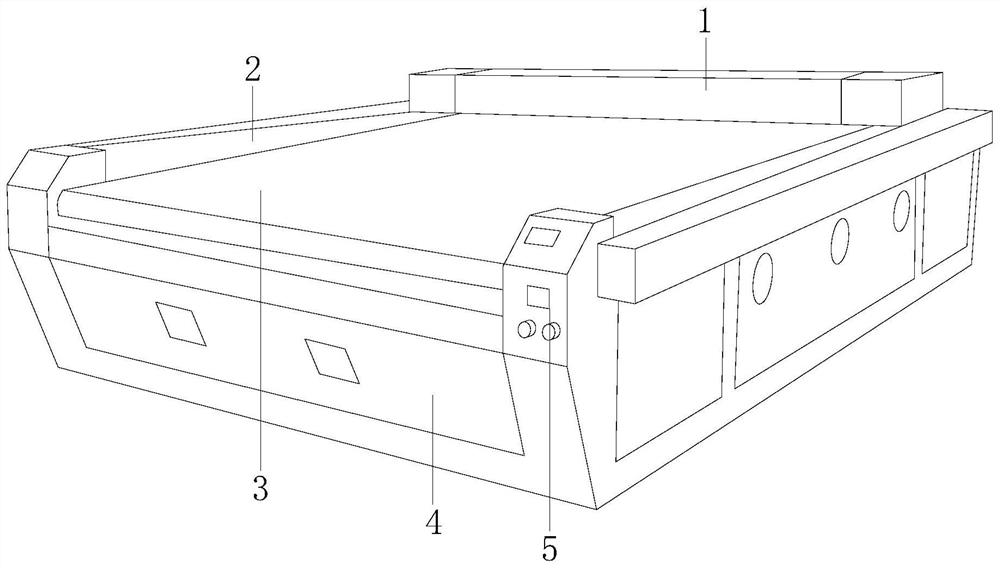

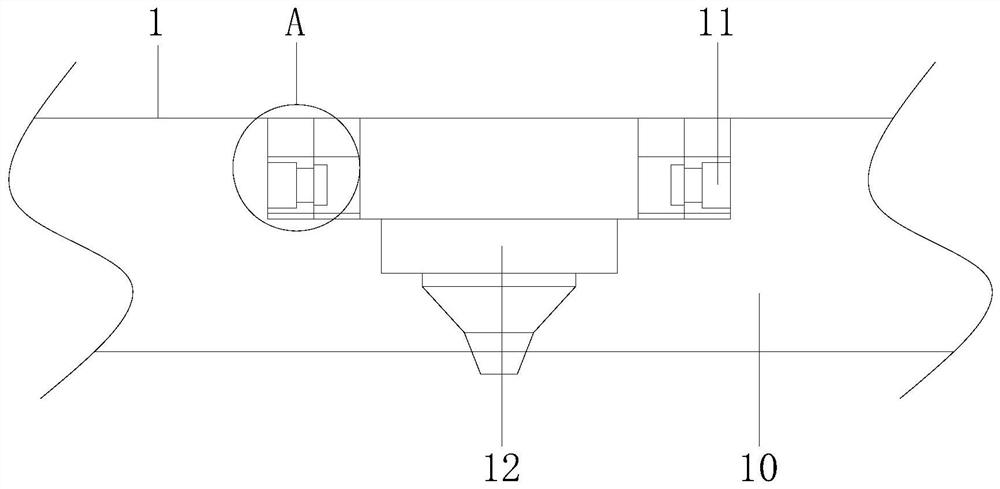

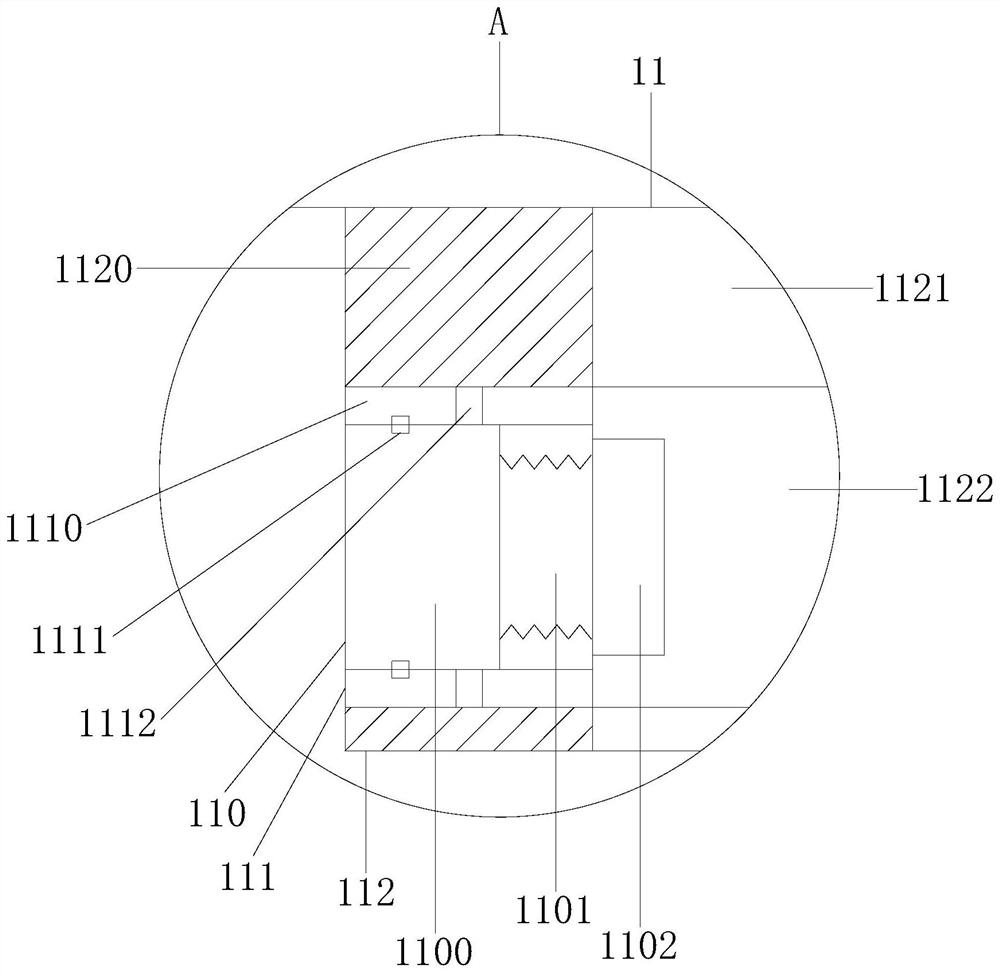

[0026] Example 1 see Figure 1-6 , the present invention provides a technical solution for an ultra-high pressure stone water jet cutting machine: its structure includes a cutting frame 1, a lifting side frame 2, a conveying table 3, a cutting machine frame 4, and a controller 5, and the lifting side frame 2 realizes The cutting frame 1 is lifted and adjusted to cut depth and water mist spraying height distance, the cutting frame 1 is installed and connected with the lifting side frame 2, the delivery table 3 is installed on the cutting machine frame 4, and the cutting machine frame 4. A controller 5 is installed. The cutting frame 1 is composed of a mobile main frame 10, a water spray device 11, and a cutting head 12. Installed and connected with the cutting machine head 12, the water spray device 11 includes a spraying machine head 110, a moving turntable 111, and a spray frame 112, and the spraying machine head 110 is installed on the spray frame 112, and the moving turntab...

Embodiment 2

[0028] Example 2 see Figure 7, the present invention provides a technical solution for an ultra-high pressure stone water jet cutting machine: the structure of the spray structure 610 includes a spray swivel 6100, a structural mounting plate 6101, a low-pressure water sprayer 6102, and a mist spray fan 6103. The spray structure 610 There are more than 3 and are arranged in a ring shape, so that the sprayed water rotates in a spiral shape to clean up the dirt after peeling off in a large range. There are low-pressure water sprayers 6102 and mist spray fans 6103, and the mist spray fans 6103 are used to spray cooling air for cooling.

[0029] The spray structure 610 is installed on the water spray ring 61, and there are more than 3 and arranged in a ring shape to clean up the dirt after peeling off in a large range. The water spray ring 61 rotates to make the water spray spirally rotate to clean the sludge At this time, the mist blower 6103 sprays cooling air for cooling, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com