Rubber pillar welding device and use method

A welding equipment and glue column technology, applied in the field of medical devices, can solve the problems of low product assembly efficiency, inability to guarantee the consistency of products and products, and achieve the effects of improving quality and product consistency, improving efficiency, and easy device operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

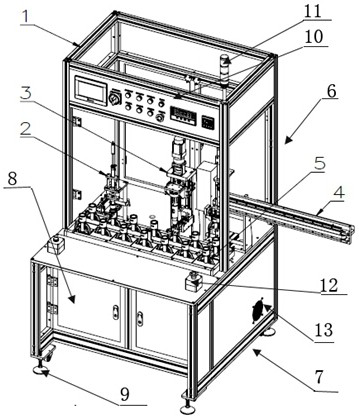

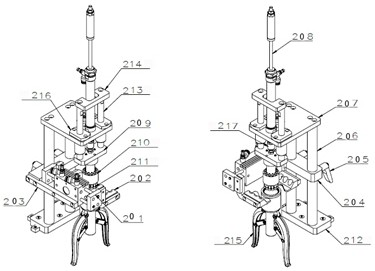

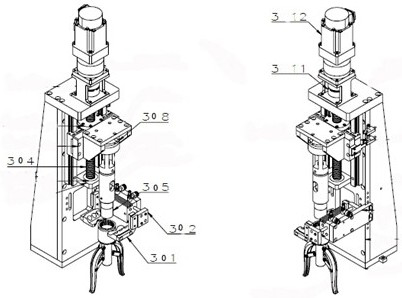

[0033] Such as Figures 1 to 4The shown glue column welding equipment of the present invention comprises a frame 1, a blade detection mechanism 2, a blade welding mechanism 3, a transfer mechanism 4 and a jig circulation structure 5, and the frame 1 is provided with an upper structure 6 and a lower structure Structure 7, the lower structure 7 is provided with supporting feet 9 and the first door 8, the inside of the first door 8 is a storage box, the upper structure 6 is a metal frame, the side of the metal frame includes a control panel 10, and the upper part of the metal frame is provided with three Color lamp 11, blade welding mechanism 3 includes pneumatic finger 1 302, clamp 1 301, motor 312, thermal resistance 305 and finger cylinder 1 302, blade detection mechanism 2 in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com