A vertical rolling mill cardan shaft hoisting tool and hoisting method

A hoisting tool and a technology for vertical rolling mills, which are applied in transportation and packaging, load hanging components, etc., can solve problems such as damage to the cardan shaft body structure of vertical rolling mills, shorten the service life of equipment, and slow construction progress, so as to improve hoisting Safety, reduction of shaking problems, and overall improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

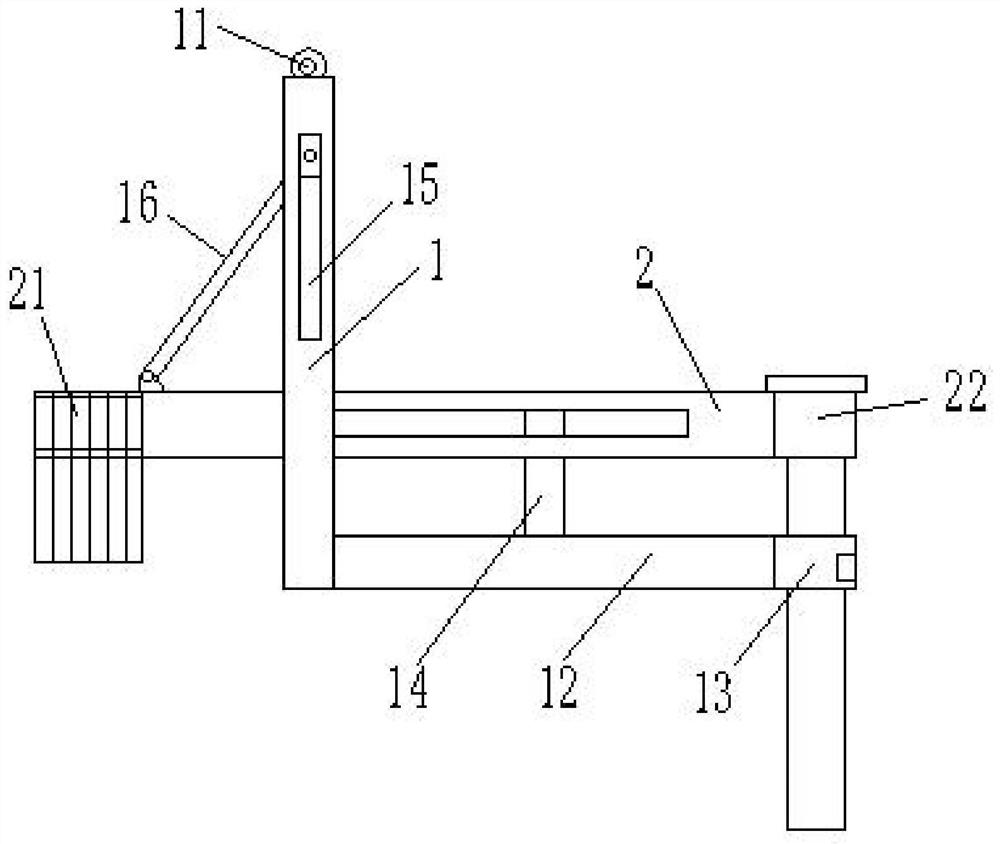

[0025] Such as Figure 1 to Figure 3 As shown, a vertical rolling mill cardan shaft hoisting tool includes a main boom 1 and an auxiliary boom 2, the main boom 1 and the auxiliary boom 2 are distributed in a cross-shaped structure, and the main boom 1 is equipped with an auxiliary support assembly And the lifting lug 11, the lifting device can be connected by using the lifting lug 11, and the auxiliary support assembly is used for the auxiliary support of the shaft body of the universal joint shaft before the universal joint shaft is fully lifted.

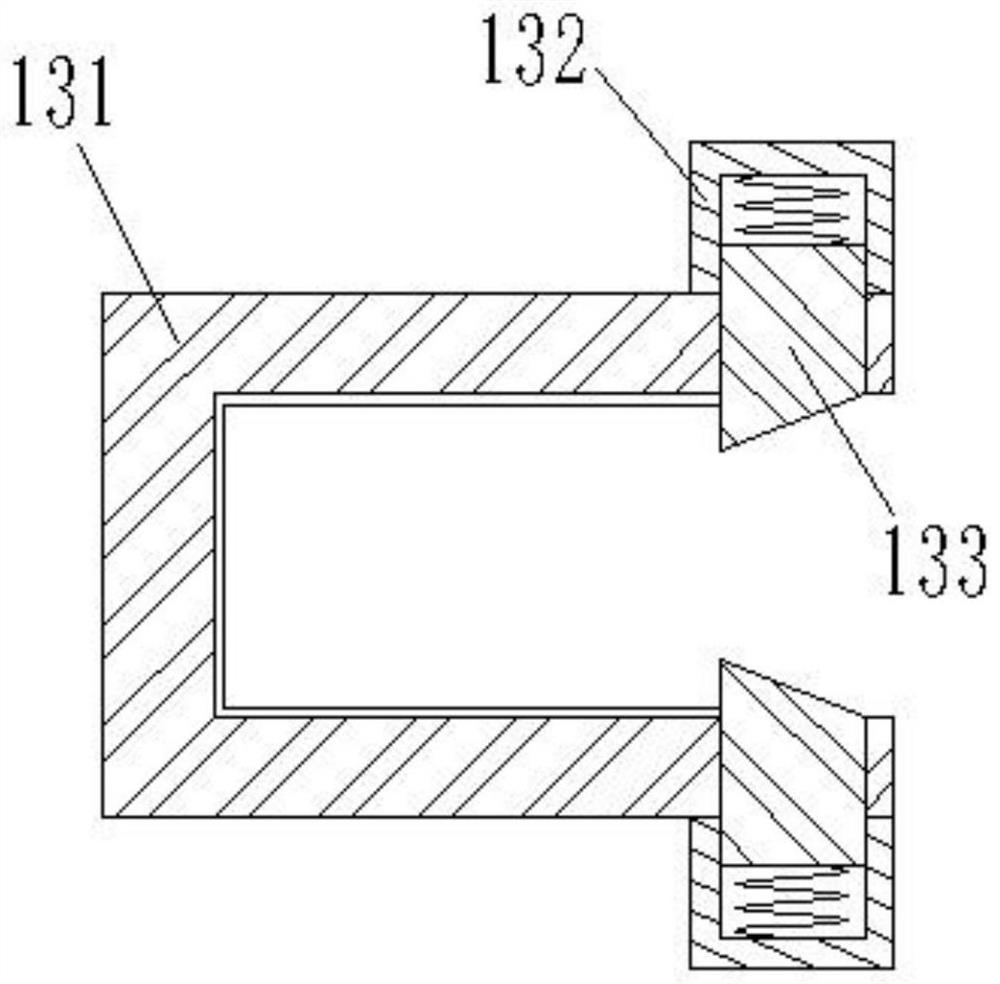

[0026] Wherein, the auxiliary support assembly includes an auxiliary support rod 12, a connecting frame 13 and a reinforcing rod 14, the auxiliary support rod 12 is fixedly connected to the main boom 1 and is located below the auxiliary boom 2, and the auxiliary support rod 12 is far away from the main boom 1 One end of one end is connected with the connecting frame 2 13 that is used to install the cardan shaft through the rotating...

Embodiment 2

[0031] A hoisting method of a vertical rolling mill cardan shaft hoisting tool, comprising the following steps:

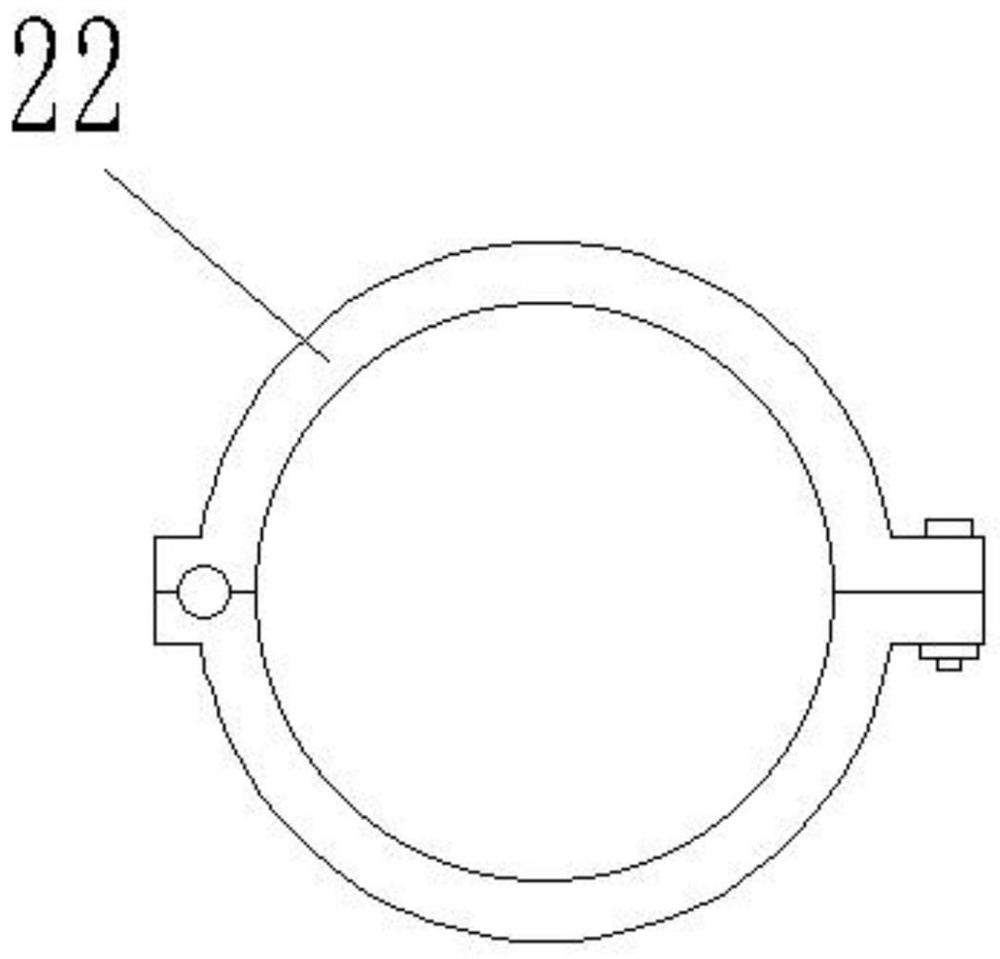

[0032] Step 1. First, the hoisting tool is completed, and the clamp is fixed to the universal shaft through the bolts in the first connecting frame 22, and the universal bearing is supported through the supporting part 131 in the second connecting frame 13, and the clamping block 133 is paired. The cardan shaft is connected to ensure that the cardan shaft slides freely inside the supporting part 131;

[0033] Step 2. Connect the lifting lug 11 through the hook of the workshop driving, and gradually lift the main boom 1 and the auxiliary boom 2. In the process, the main boom 1, the auxiliary support rod 12, the second connecting frame 13 and the reinforcing rod 14 The suspension rod 2 moves horizontally, and the support rod 16 drives the slider to move up along the chute 15. The shaft body of the cardan shaft is gradually lifted under the action of the auxiliary sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com