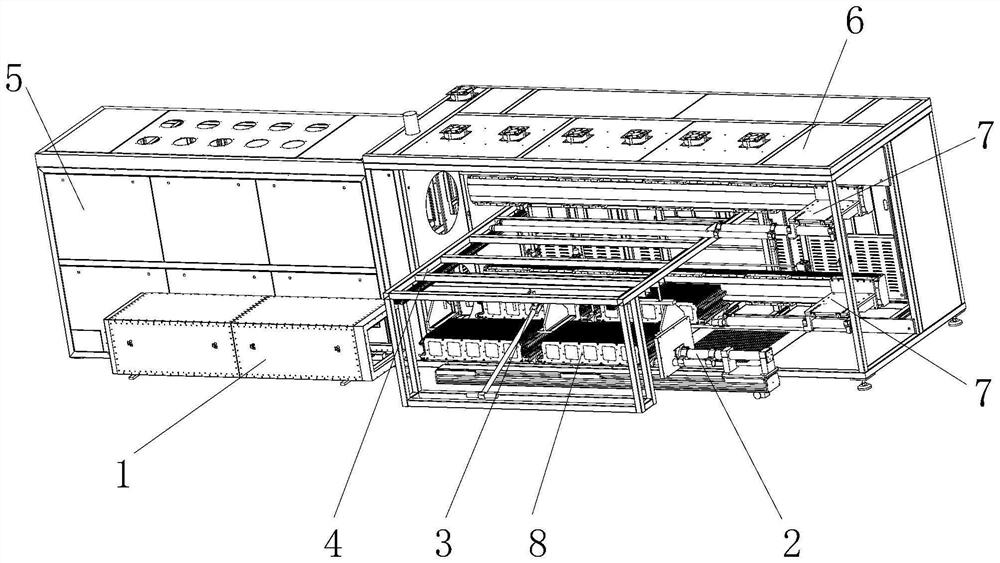

An experimental device for a tubular peCVD preheating system

An experimental device and tubular technology, applied in metal material coating process, coating, gaseous chemical plating, etc., can solve problems such as enlarging the furnace body, and achieve the effect of improving accuracy, low cost and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below with reference to the accompanying drawings and specific embodiments.

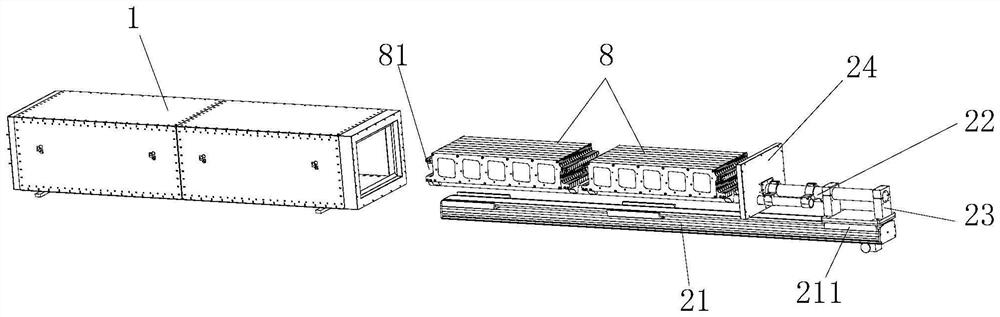

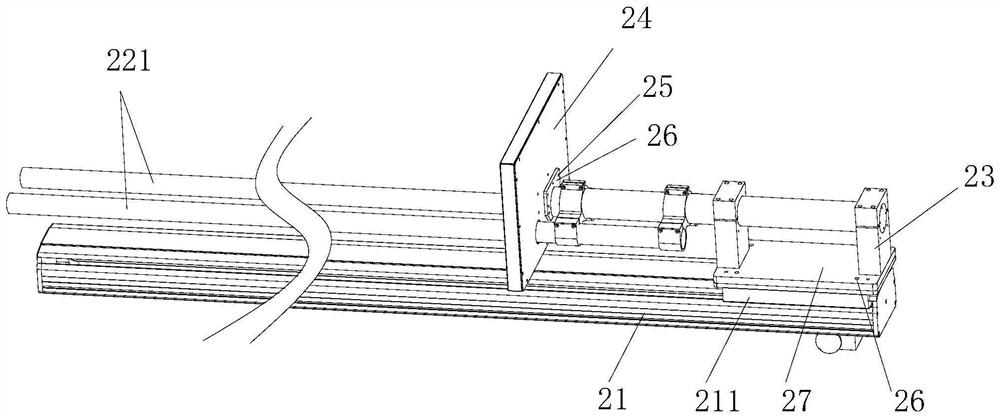

[0030] To verify the preheating method of the tubular PECVD preheating system, it is necessary to put the boat body 8 into a device to heat up, come out after reaching a certain temperature, and then put it into the reaction chamber for the process, and then record the process time, if the process time is shortened And the corresponding increase in energy consumption meets expectations, the feasibility of the preheating method can be verified. Since the temperature of the boat body 8 is relatively high after preheating, it is infeasible to lift the boat body 8 simply by manpower, so a set of mechanisms is required to put the preheated boat body 8 into the reaction chamber. On the basis of the existing equipment, it is the purpose of the present invention to design a set of mechanism to heat the boat body 8 and then send it into the equi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com