Large-span steel box arch rib segmented assembling and integral lifting construction method

A technology of overall lifting and construction method, applied in arch bridges, erecting/assembling bridges, bridge parts, etc., can solve the problems of high risk of high-altitude operation, difficult hoisting of arch rib segments, limited hoisting capacity, etc., to reduce welding quality control. Difficulty, reduce the difficulty of linear control, and ensure the effect of accuracy and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

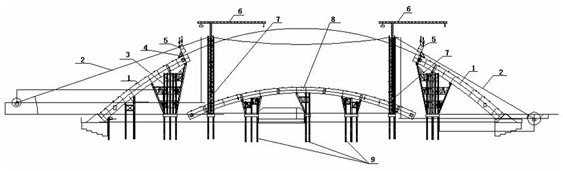

[0058] A construction method for the segmental assembly of large-span steel box arch ribs and overall lifting, such as figure 1 and 2 shown, including the following steps:

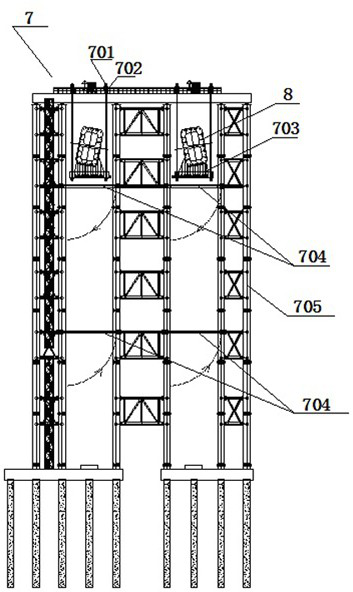

[0059] S1. Set up the side arch section support system 3, the middle arch section support system 9, and the door-type integral lifting support 7. There is a passage channel between the support supports of the middle arch section support system 9, and the portal-type integral lifting support 7 is in the middle. The two ends of the design position of the arch rib 8 in the arch section;

[0060] S2. The arch rib 1 of the side arch section is installed at the designed bridge position;

[0061] S3. The arch rib 8 of the middle arch section is assembled into a whole below the designed bridge position and above the support system 9 of the middle arch section;

[0062] S4. Hoisting construction of arch rib 8 in the middle arch section:

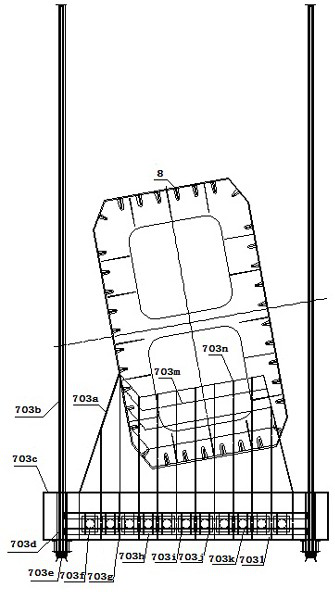

[0063] S4.1 A stainless steel plate is laid on the bearing platform of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com