Optimization method for ball throwing temporary plugging steering fracturing of shale gas horizontal well

An optimization method and technology for horizontal wells, applied in design optimization/simulation, earthwork drilling, wellbore/well components, etc., can solve problems such as the optimization method of construction parameters for temporary plugging and fracturing without perfecting the ball

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with the accompanying drawings.

[0037] An optimization method for shale gas horizontal well throwing temporary plugging and turning to fracturing, including the following steps:

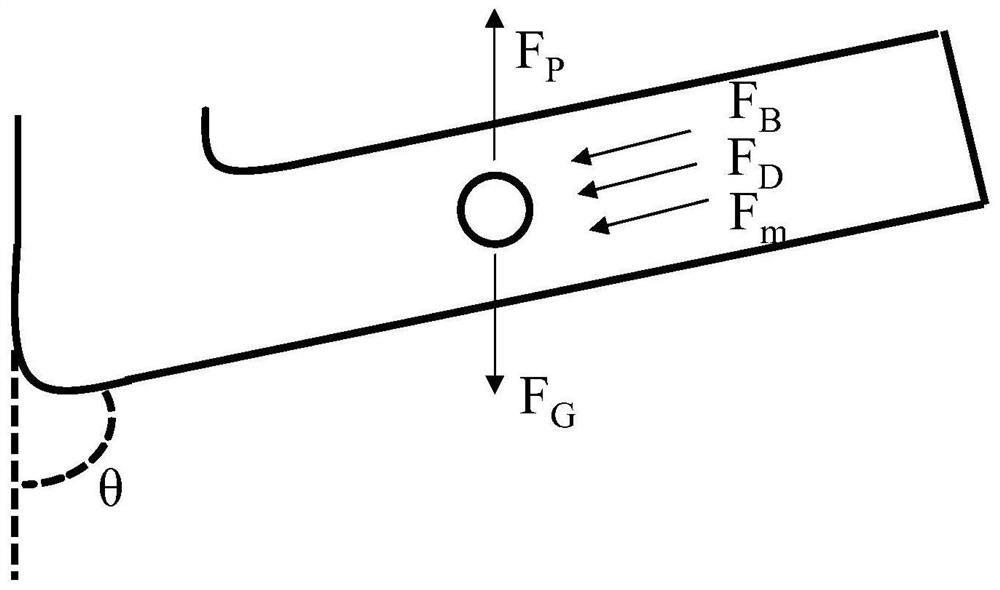

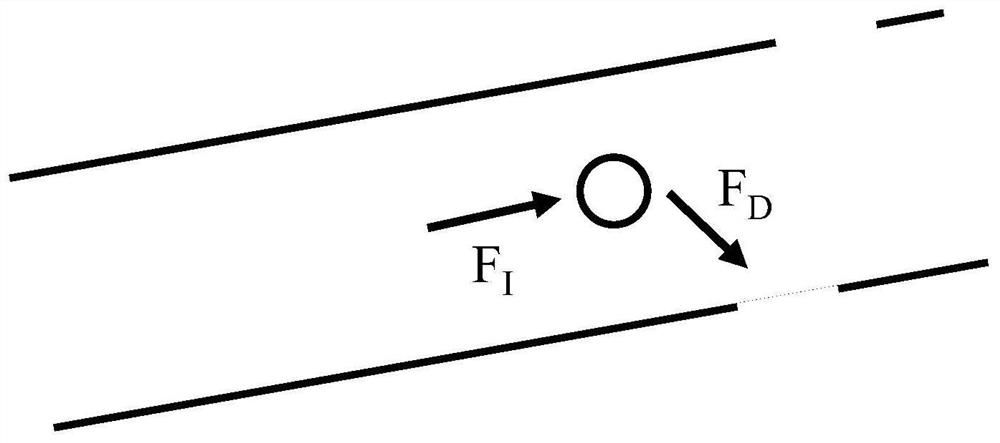

[0038] (1) Analyze the force of the temporary plugging ball when it migrates in the wellbore. There is mainly gravity F G , pressure gradient force F P , resistance F d , additional mass force F m , Basset force F B and the wall effect f W influence, see figure 1 , the model can be used for the migration of temporary plugging balls in the whole wellbore in vertical or horizontal wells through the change of wellbore inclination.

[0039] (2) According to the principle of mechanical balance, the formula of the migration velocity of the temporary plugging ball in the wellbore is established.

[0040]

[0041] in,

[0042] v b Temporary blocking ball moving speed m / s;

[0043] ρ b ρ l Density of temporary pluggi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com