Poached egg formula and production process

A production process and technology for poached eggs, applied in the field of food processing, can solve the problems of loss of nutrients in egg yolk, single taste of poached eggs, short storage time, etc., and achieve the effects of improving nutritional effect, unique taste and ensuring beautiful appearance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

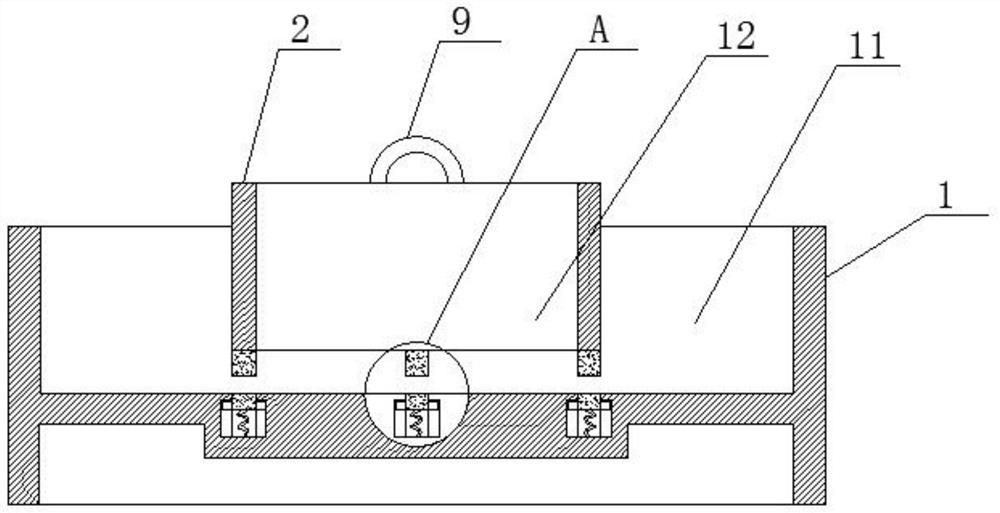

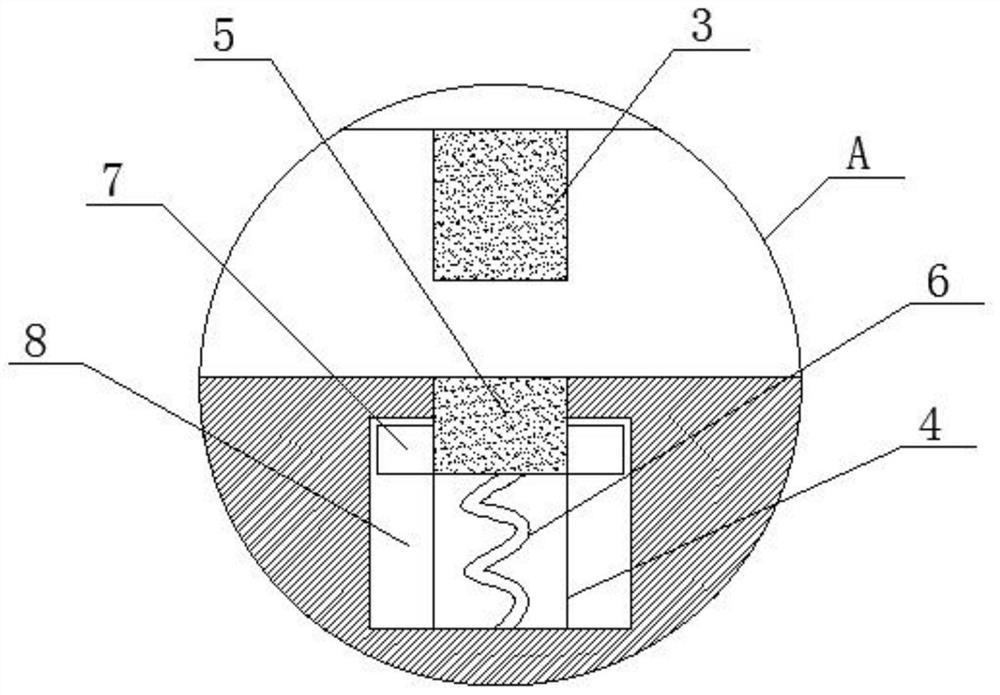

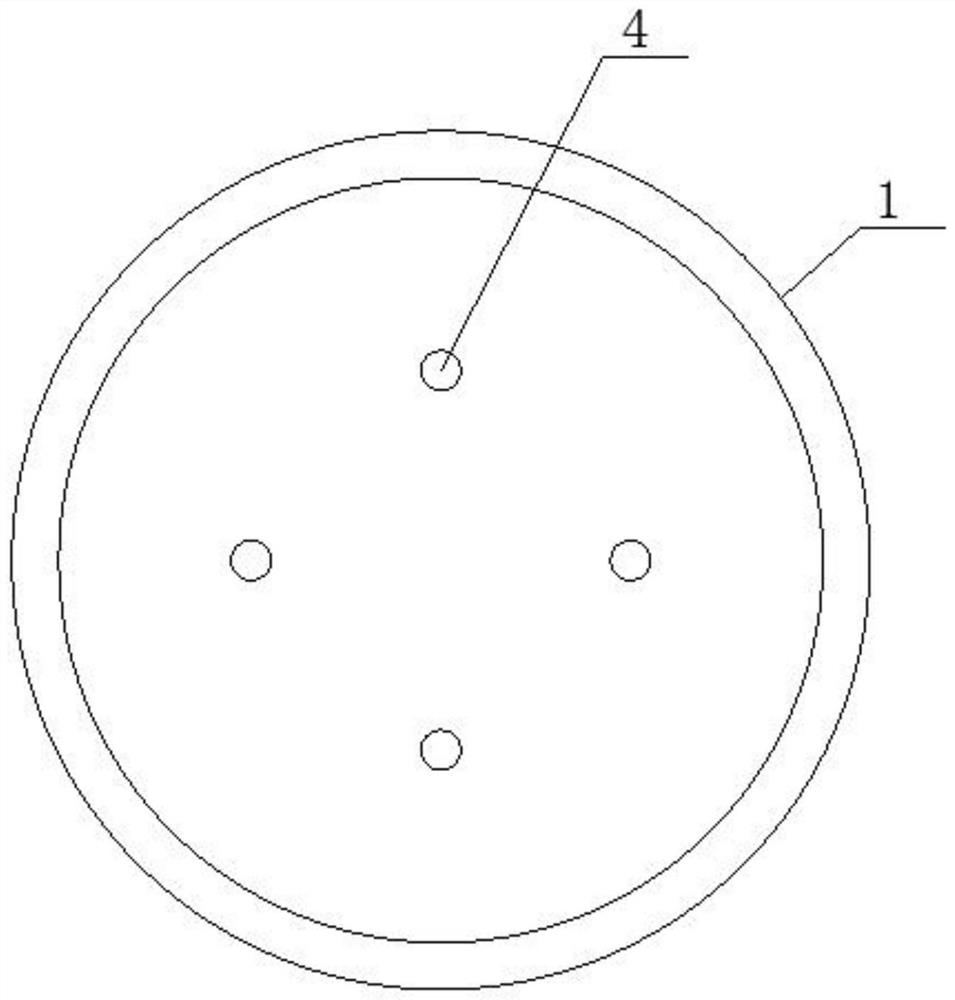

[0030] The invention provides a poached egg production process, which is characterized in that: the bottom of the poached egg is a round egg white, the middle of the upper part is a round egg yolk, the shape of the outer ring is irregular circle, the diameter of the poached egg is 5-10 cm, and the diameter of the egg yolk is 3-10 cm. 7cm;

[0031] A poached egg formula and production process, including protein formula and egg yolk formula, the weight ratio of the protein formula and egg yolk formula is 21:9, its total weight is 30, the raw material parts of the protein formula are 35 parts of protein powder, corn 20 parts of oil, 0.5 part of xanthan gum, 82 parts of drinking water, 0.8 part of salt, 5 parts of potato starch and 0.02 part of flavor enhancer. The raw materials of the egg yolk formula are 30 parts of egg yolk liquid, 10 parts of maltodextrin, carrot 1.5 parts of vegetarian food, 50 parts of drinking water, 1 part of salt, 0.02 parts of flavor enhancer, 10 parts o...

Embodiment 2

[0039]The invention provides a poached egg production process, which is characterized in that: the bottom of the poached egg is a round egg white, the middle of the upper part is a round egg yolk, the shape of the outer ring is irregular circle, the diameter of the poached egg is 5-10 cm, and the diameter of the egg yolk is 3-10 cm. 7cm;

[0040] A kind of poached egg formula and production process, comprise protein formula and egg yolk formula, the weight ratio of described protein formula and egg yolk formula is 23:7, and its total weight is 30, and the raw material portion of described protein formula is protein powder 35 parts, corn 20 parts of oil, 0.5 part of xanthan gum, 82 parts of drinking water, 0.8 part of salt, 5 parts of potato starch and 0.02 part of flavor enhancer. The raw materials of the egg yolk formula are 30 parts of egg yolk liquid, 10 parts of maltodextrin, carrot 1.5 parts of vegetarian food, 50 parts of drinking water, 1 part of salt, 0.02 parts of fla...

Embodiment 3

[0048] The invention provides a poached egg production process, which is characterized in that: the bottom of the poached egg is a round egg white, the middle of the upper part is a round egg yolk, the shape of the outer ring is irregular circle, the diameter of the poached egg is 5-10 cm, and the diameter of the egg yolk is 3-10 cm. 7cm;

[0049] A kind of poached egg formula and production process, comprising protein formula and egg yolk formula, the weight ratio of described protein formula and egg yolk formula is 25:5, and its total weight is 30, and the raw material portion of described protein formula is protein powder 35 parts, corn 20 parts of oil, 0.5 part of xanthan gum, 82 parts of drinking water, 0.8 part of salt, 5 parts of potato starch and 0.02 part of flavor enhancer. The raw materials of the egg yolk formula are 30 parts of egg yolk liquid, 10 parts of maltodextrin, carrot 1.5 parts of vegetarian food, 50 parts of drinking water, 1 part of salt, 0.02 parts of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com