Floating guide mechanism

A guiding mechanism and lifting technology, which is applied in the field of stamping dies, can solve the problems of insufficient mold space and the inability to place floating guide devices, etc., and achieve the effects of simple and ingenious structure, space saving and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

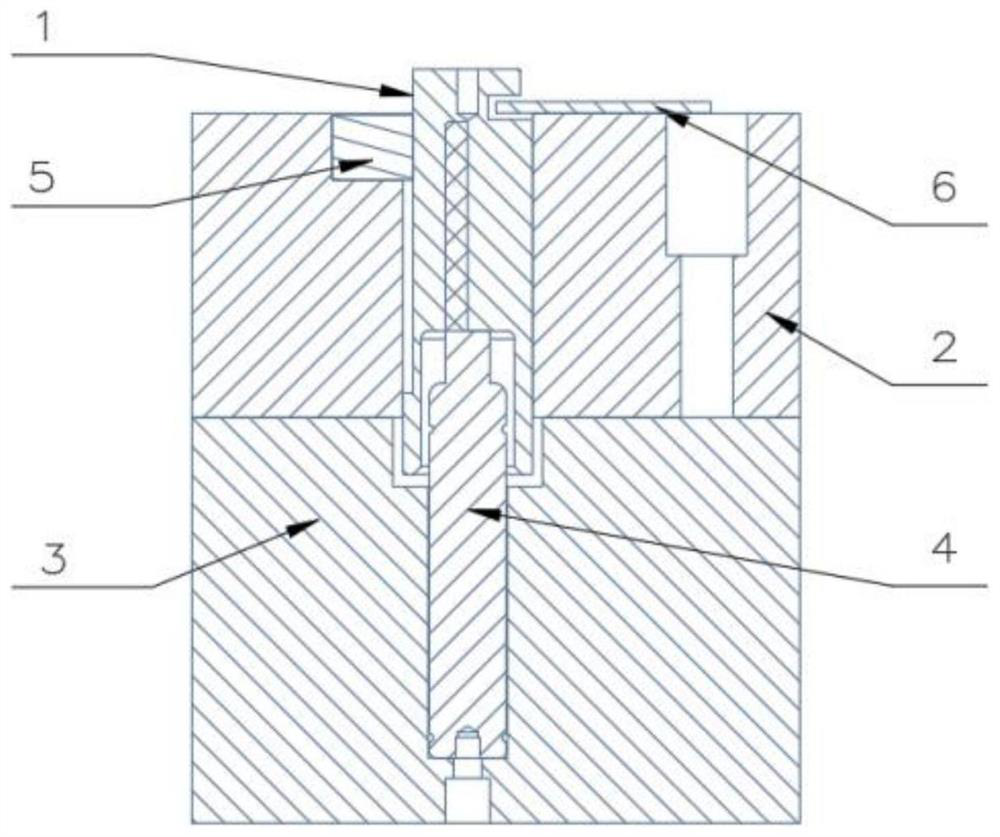

[0015] Such as figure 1 , figure 2 , the structure of the present invention is, including pin side guide post 1, guide post fixing plate 2, mold base 3, nitrogen spring 4,

[0016] The upper side of the pin edge guide post 1 has a limit pin edge on the peripheral surface of one side, and a guide bar 6 is installed horizontally outward in the limit pin edge, and the lower part of the pin edge guide post 1 is processed with a guide corrugated along the other side of the circumferential surface opposite in diameter. The lower end surface of the pin edge guide post 1 is provided with two-stage blind hole type nitrogen spring installation grooves;

[0017] A guide post installation groove is vertically opened in the guide post fixing plate 2, and the pin edge guide post 1 passes through the guide post installation groove. The upper edge of the guide post installation groove is provided with a stepped pressure plate installation groove, and the pressure plate installation groove ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com