Full-automatic hydraulic hoop production device

A production device, fully automatic technology, applied in the direction of feeding device, positioning device, storage device, etc., can solve the problems of affecting product quality, unable to meet mass production, low degree of automation, etc., to meet continuous mass production, improve Product quality and work efficiency, the effect of reducing conveying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

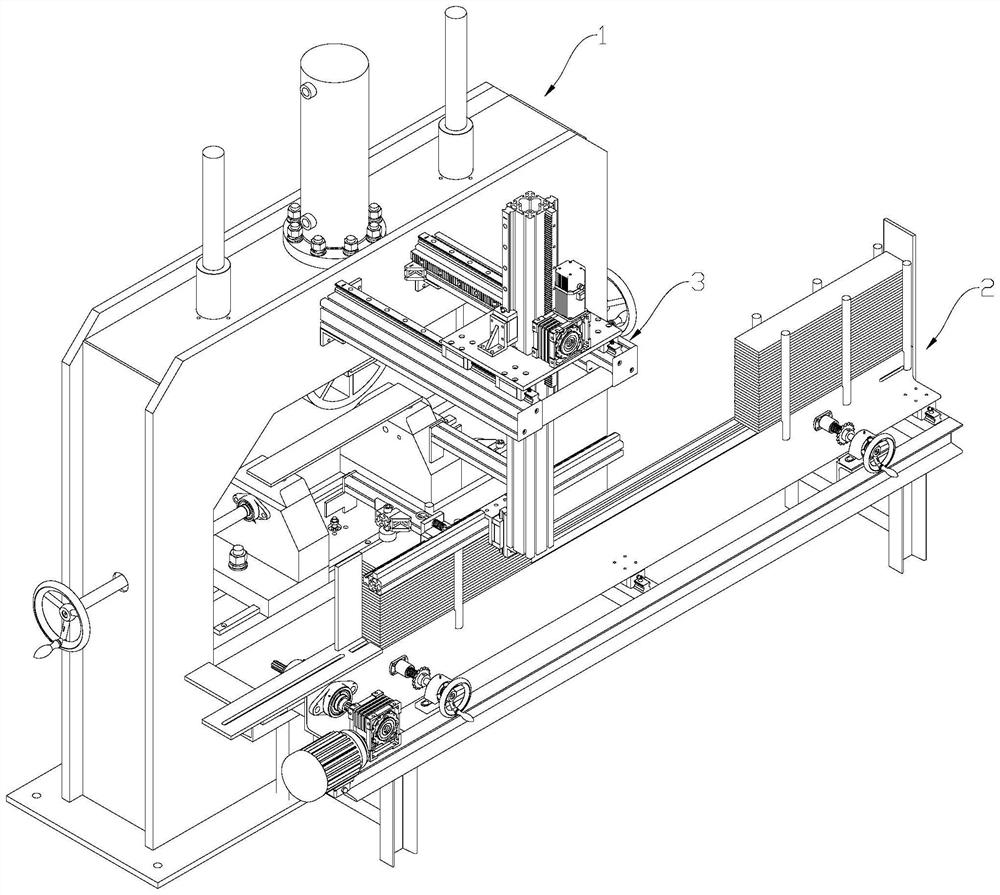

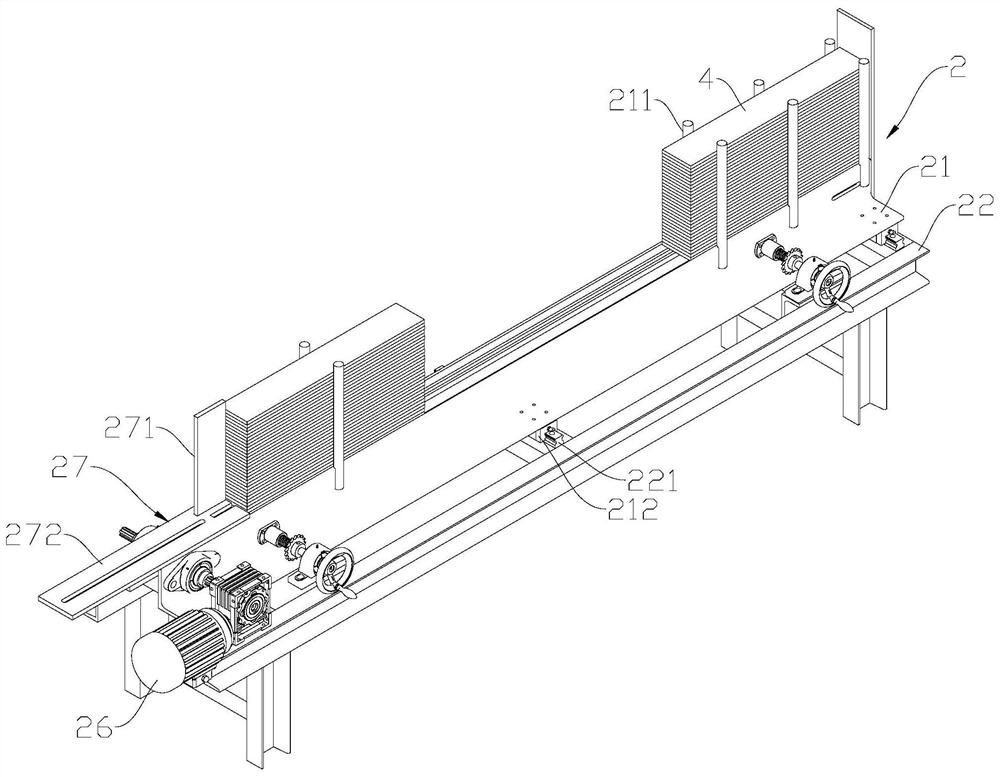

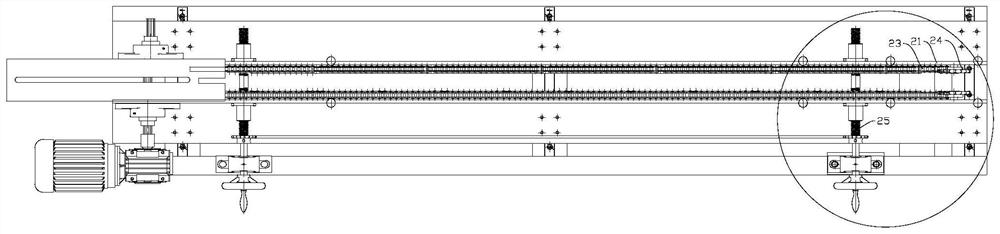

[0063] Please refer to Figure 1-9 , the present embodiment provides a fully automatic hydraulic hoop production device, including a hydraulic hoop machine 1 and a feeding mechanism arranged on one side of the hydraulic hoop machine 1, and the feeding mechanism is used to send the hoop sheet 4 into and Send out the hydraulic hoop machine 1.

[0064] Let the axial direction parallel to the stamping die 14 of the hydraulic hoop machine 1 be the horizontal longitudinal direction, the direction perpendicular to the horizontal longitudinal direction be the horizontal transverse direction, and the direction perpendicular to the horizontal transverse direction and the horizontal longitudinal direction be the vertical direction; The feeding mechanism includes a longitudinal feeding mechanism, and the longitudinal feeding assembly includes a manipulator 5 for fixing the hoop plate 4 and a manipulator 3 for driving the manipulator 5 to move vertically and / or horizontally; The manipulat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com