Screening device for melting forming of copper handicraft, and melting forming process of screening device

A melting molding and screening device technology, applied in manufacturing tools, casting molding equipment, casting molds, etc., can solve problems such as waste of resources, troublesome media screening, and inflexible modeling, so as to improve work efficiency and prevent waste of media. , the effect of improving the efficiency of screening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

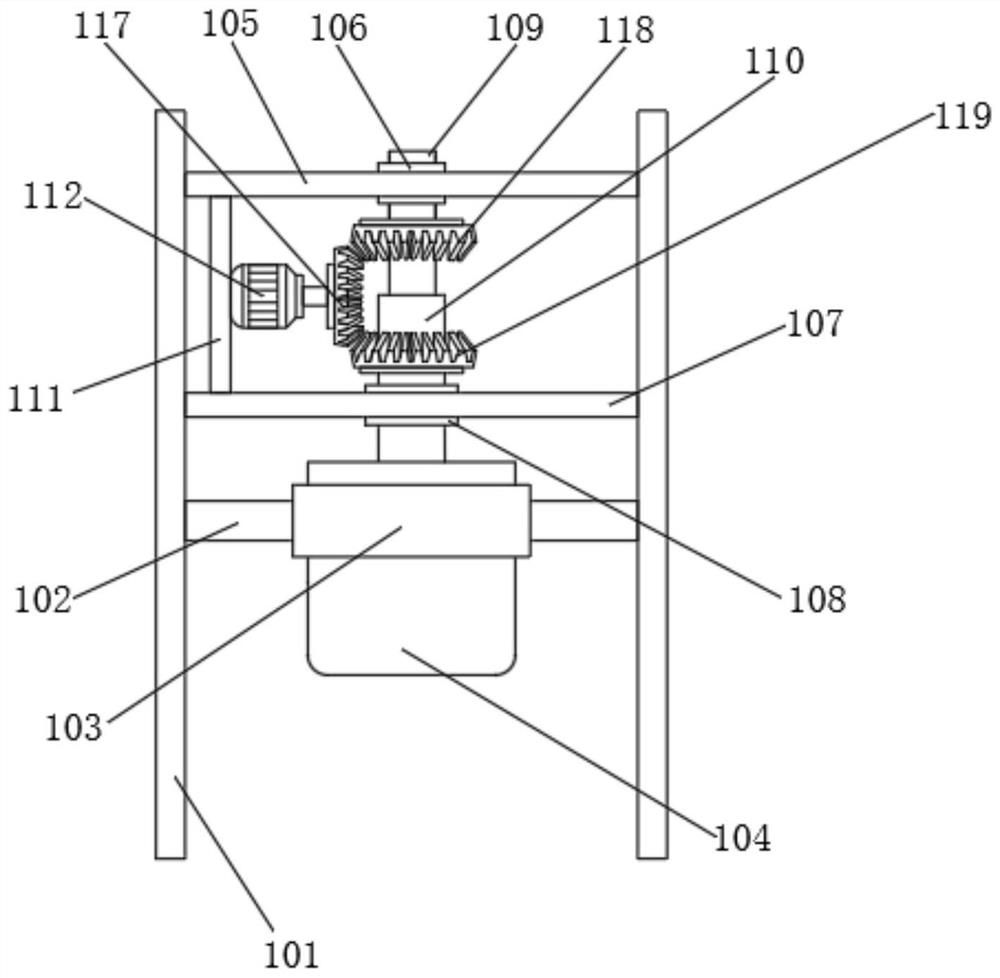

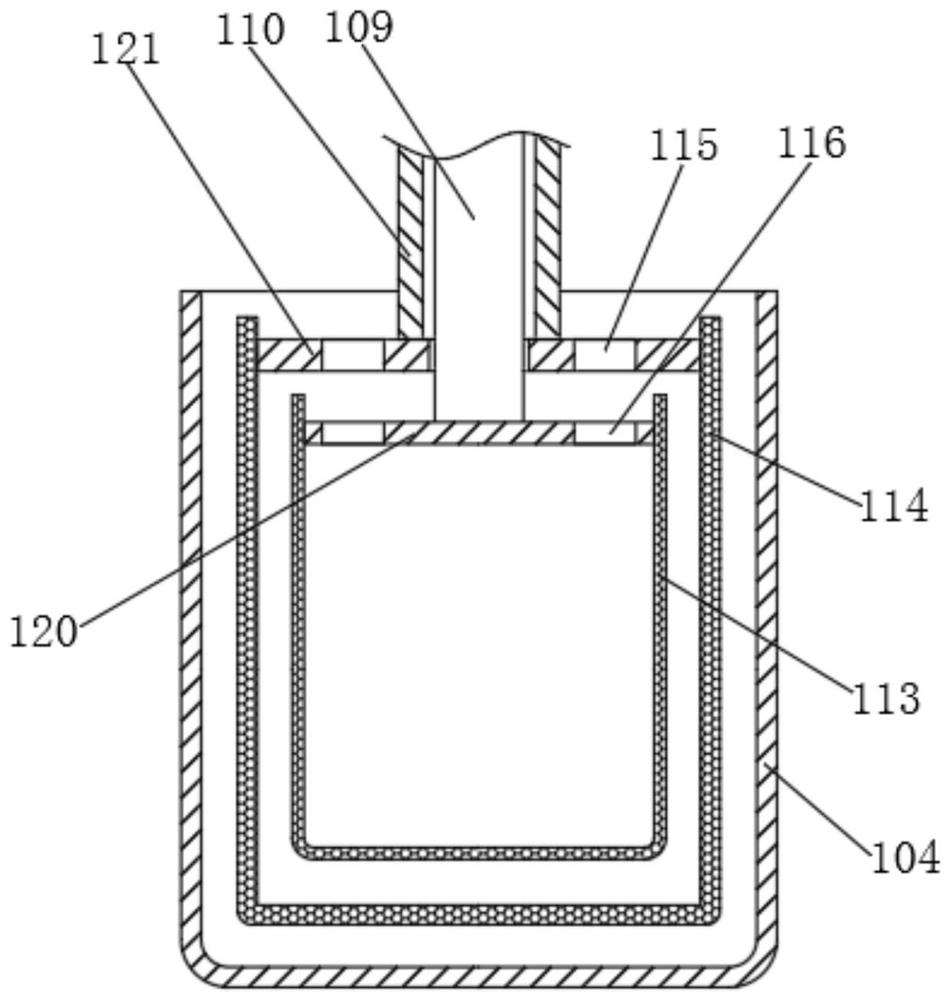

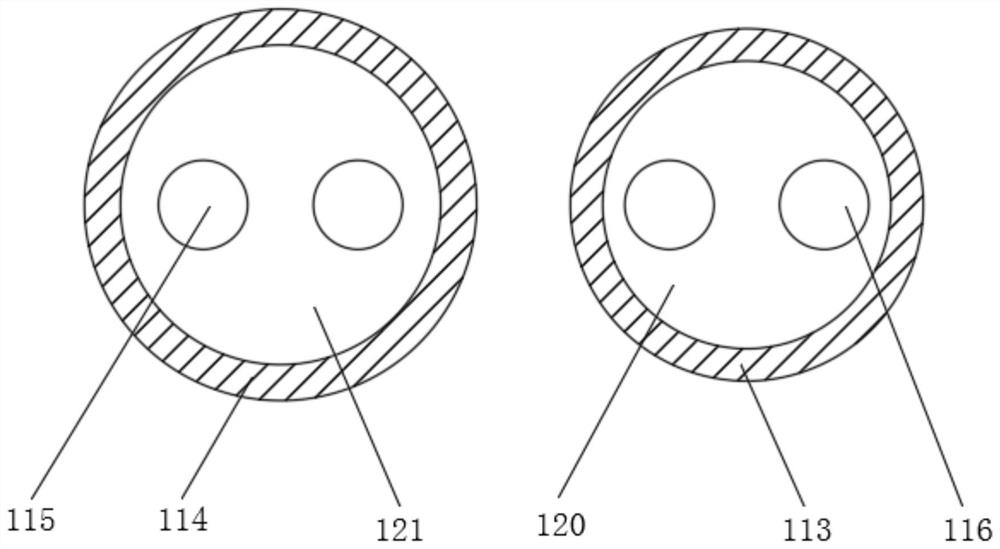

[0046] see figure 1 , a screening device for melting and forming copper handicrafts, comprising two support columns 101, a crossbar 102 is fixedly connected to the outer wall of one side of the support column 101, and a support ring 103 is fixedly connected to the end of the crossbar 102 away from the support column 101, The inner wall of the support ring 103 is threadedly connected with a receiving barrel 104, the top of the cross bar 102 is provided with a first support rod 105 fixedly installed on the outer wall of the support column 101, and the middle part of the first support rod 105 is fixedly installed with a first bearing 106 , between the first support rod 105 and the cross bar 102, there is a second support rod 107 fixedly installed on the outer wall of the support column 101, a second bearing 108 is fixedly installed in the middle of the second support rod 107, and the inner ring of the first bearing 106 The inner wall of the second bearing 108 is fixedly connected...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com