Novel battery pack high-voltage control method

A high-voltage control and battery pack technology, which is applied in the field of high-voltage control of new battery packs and high-voltage power-on control of electric vehicle battery packs, can solve problems such as the adhesion of the total positive relay, failure to start and loss of electric vehicles, etc., and achieve reduction Control link, shorten the time of high-voltage power supply, and avoid the effect of failure to start and unable to drive

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

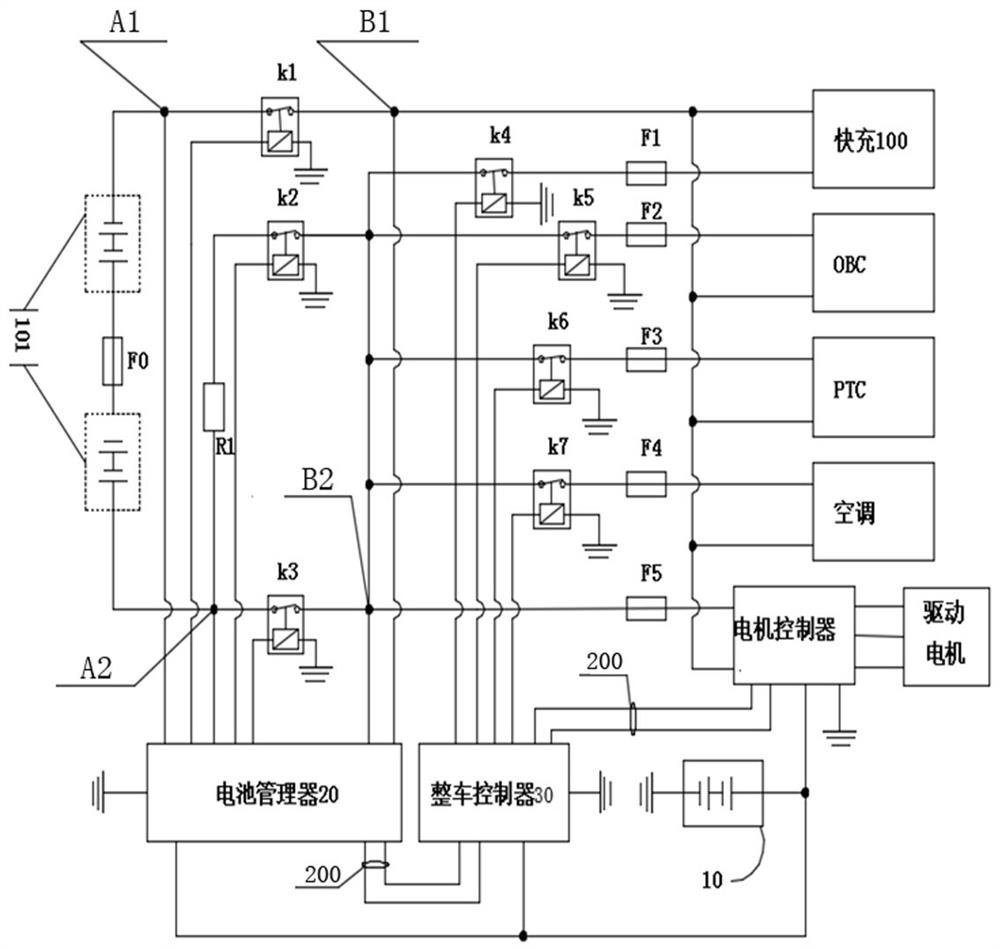

[0010] The high-voltage circuit of the present invention includes: control power supply 10; battery manager 20; battery module 101; pre-charging group R1; total negative relay k1; pre-charging relay k2; total positive relay k3; fast charging relay k4; OBC relay k5; PTC Relay k6; air conditioner relay k7; main circuit fuse FU0; fast charge fuse FU1; OBC fuse FU2; PTC fuse FU3; air conditioner fuse FU4; motor control fuse FU5; ; PTC; air conditioner; motor controller; drive motor. The total positive relay k3 and the total negative relay k1 control the high-voltage power transmission of all high-voltage components of the electric vehicle. All high-voltage components are connected in parallel at the back end of the total positive relay k3 and the total negative relay k1. The front end of k1; all high-voltage components, including external charging, need high-voltage power to complete the pre-charging, and then control the power-on high-voltage power; after the pre-charging is comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com