Automatic winding device of digital printing thermal transfer printer

A thermal transfer printing machine and digital printing technology, applied in the direction of winding strips, transportation and packaging, thin material processing, etc., can solve the problem of not meeting the processing and use requirements of thermal transfer machines, and achieve a simple structure and ensure clamping. effect, the effect of increasing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

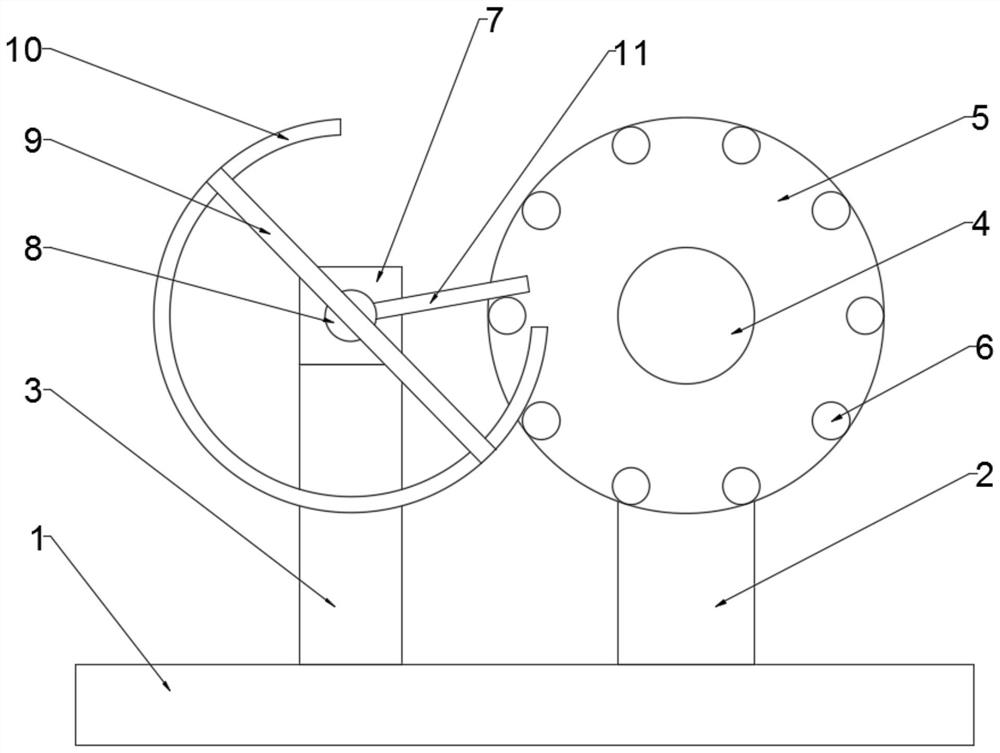

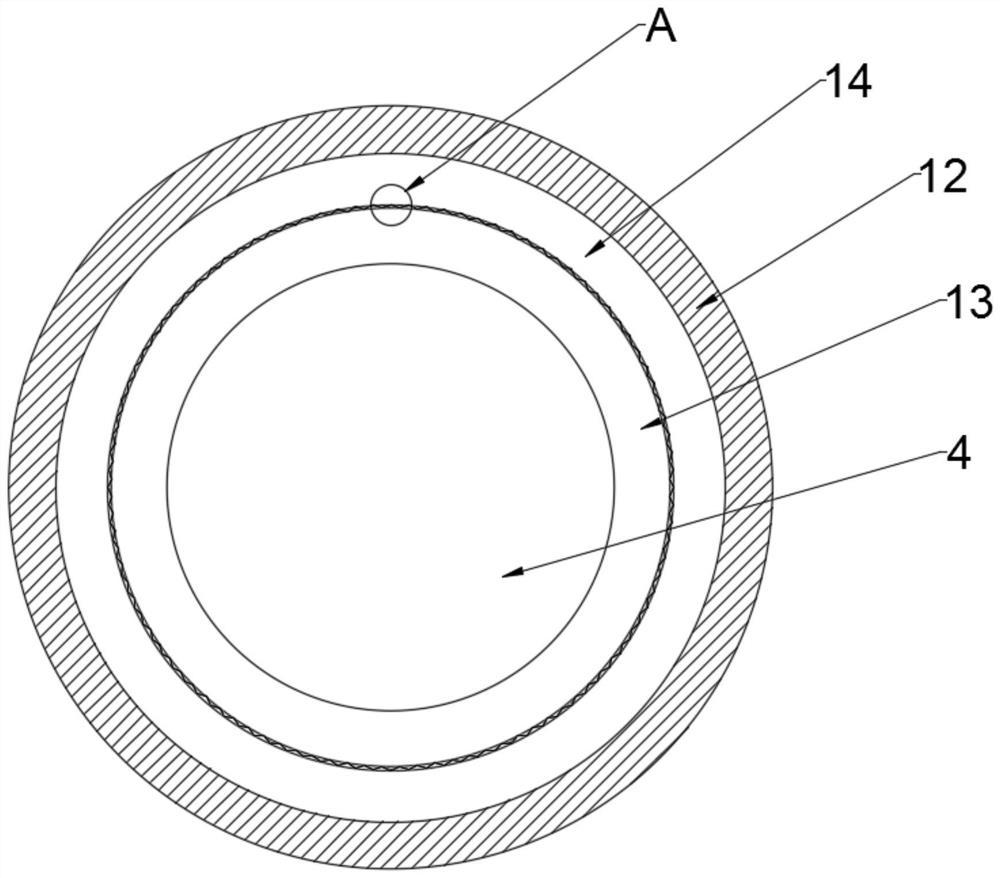

[0039] see figure 1 , an automatic winding device for a digital printing thermal transfer machine, including a base 1, a first bracket 2 vertically arranged on the right side of the upper surface of the base 1, and a fixed bracket 2 on the left side of the first bracket 2 on the upper surface of the base 1 The second bracket 3 vertically arranged, the first bracket 2 is rotatably connected with a rotating shaft 4, the outer wall of the rotating shaft 4 is sleeved with a winding roller 5, and the front side wall of the winding roller 5 is evenly distributed with a plurality of Annularly distributed cylinder 6, the top of the second support 3 is fixed with a drive motor 7, the output end of the drive motor 7 is connected with a drive shaft 8, the front end of the drive shaft 8 is fixed with a fixed rod 9 that is inclined, and the rear side wall of the fixed rod 9 A circular ring 10 is fixed on the top, an opening is provided on the circular ring 10, a driving rod 11 is fixed on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com