A segmental beam spreader

A segmental beam and spreader technology, which is applied in the direction of load hanging components, transportation and packaging, etc., can solve the problems of not being able to meet the needs of use, large swing range of segmental beams, unbalanced force of segmental beams, etc., and achieve strong practicability , Reasonable structural design, improve the effect of force balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

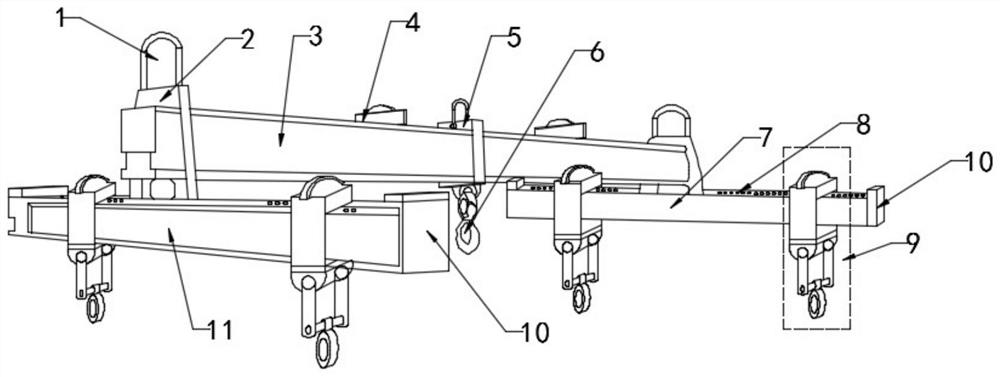

[0026] see figure 1 , In Embodiment 1 of the present invention, a segment beam hanger includes: a cross frame 3, a first bracket 7 and a second bracket 11; the upper end of the first bracket 7 and the upper end of the second bracket 11 are welded and fixed with The first fixing block 2 is integrally formed with the second bracket 11 , and the first fixing block 2 and the first bracket 7 are integrally formed; the upper end of the second bracket 11 is connected with the horizontal frame 3 through the first fixing block 2 Fixed, the upper end of the first bracket 7 is connected and fixed with the horizontal frame 3 through the first fixing block 2;

[0027] A second fixing block 5 is arranged in the middle of the horizontal frame 3, a pull ring 1 is arranged on the upper end of the second fixing block 5, and a first hook 6 is arranged at the lower end of the second fixing block 5; Blocks 10 are provided on the left and right sides of the two brackets 11 , and the first bracket ...

Embodiment 2

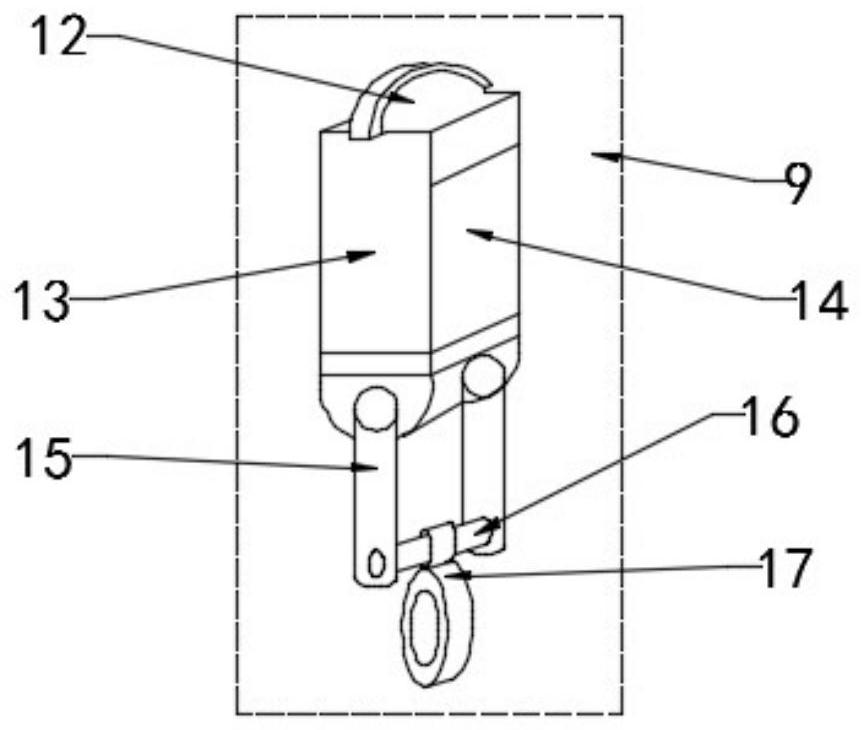

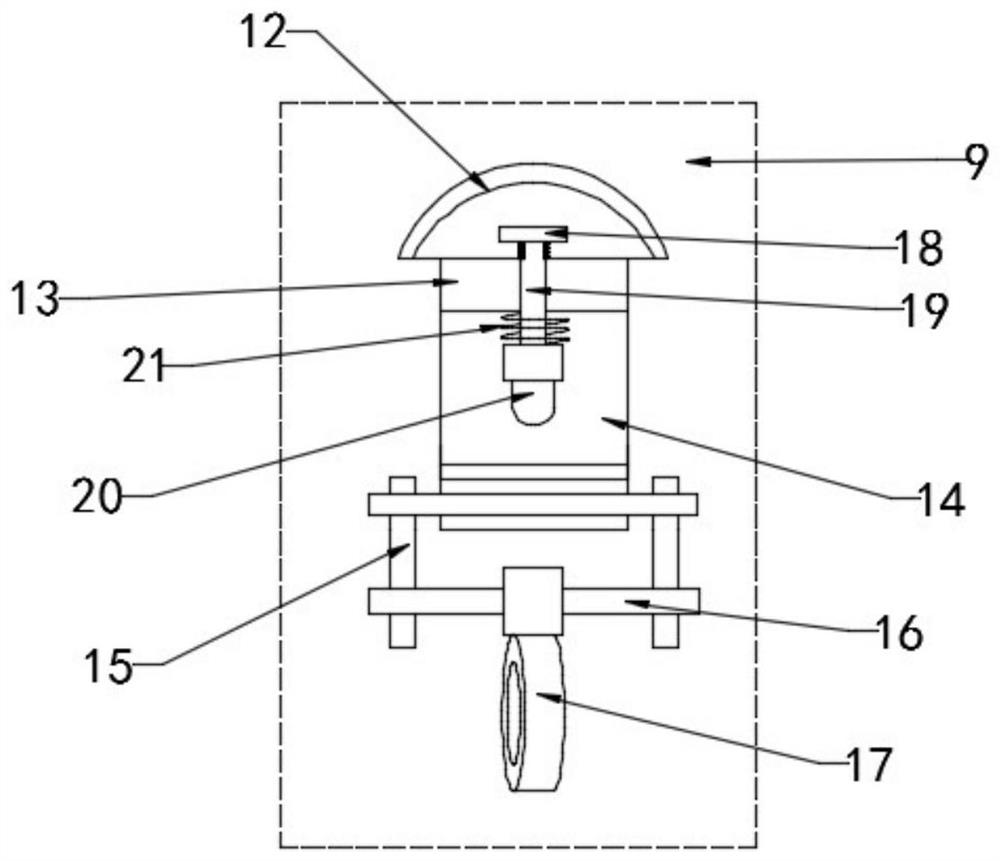

[0034] see image 3 , further, a limit assembly is provided inside the opening channel 14 of the stretching assembly 9, and the limit assembly includes a pull handle 18, a connecting rod 19 and an insertion end 20, and the upper end of the connecting rod 19 passes through the slider 13. The end part is provided with a pull handle 18, the lower end of the connecting rod 19 passes through the slider 13 and then extends into the opening channel 14, and the bottom end of the connecting rod 19 is provided with an insertion end 20;

[0035] Specifically, a compression spring 21 is installed on the portion of the connecting rod 19 between the insertion end 20 and the inner wall of the slider 13;

[0036] When the stretching assembly 9 slides on the first bracket 7 or the second bracket 11 and needs to be limited by the limiting assembly, after the stretching assembly 9 slides on the first bracket 7 or the second bracket 11 to an appropriate position, The insertion end 20 automatical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com