A pair of crusher rollers and an industrial stone crusher

A crusher and roller body technology, which is applied in the direction of grain processing, etc., can solve the problems of material waste and high cost, and achieve the effect of improving crushing quality, easy replacement, and tight connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but it should be understood that the protection scope of the present invention is not limited by the specific embodiments.

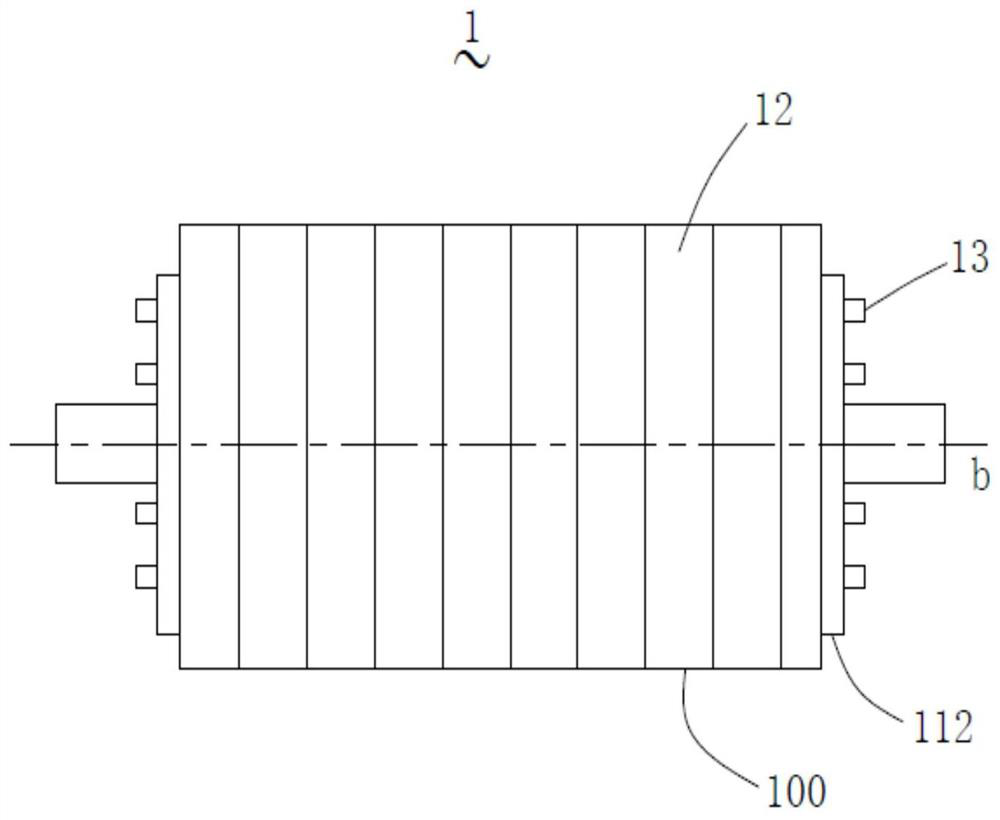

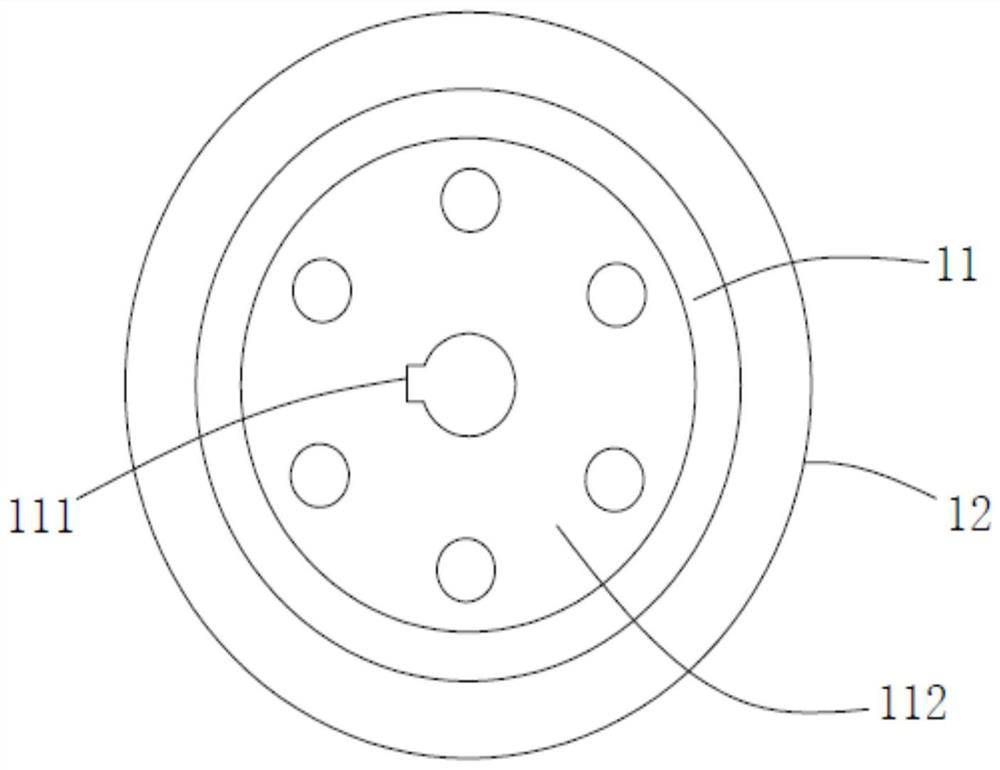

[0030] please combine figure 1 and figure 2 , the first embodiment of the present invention provides a pair of crusher rollers 1, including two roller bodies 100, the roller body 100 includes a rotating roller 11, a plurality of rolling parts 12, each of the rolling parts 12 is a ring like structure.

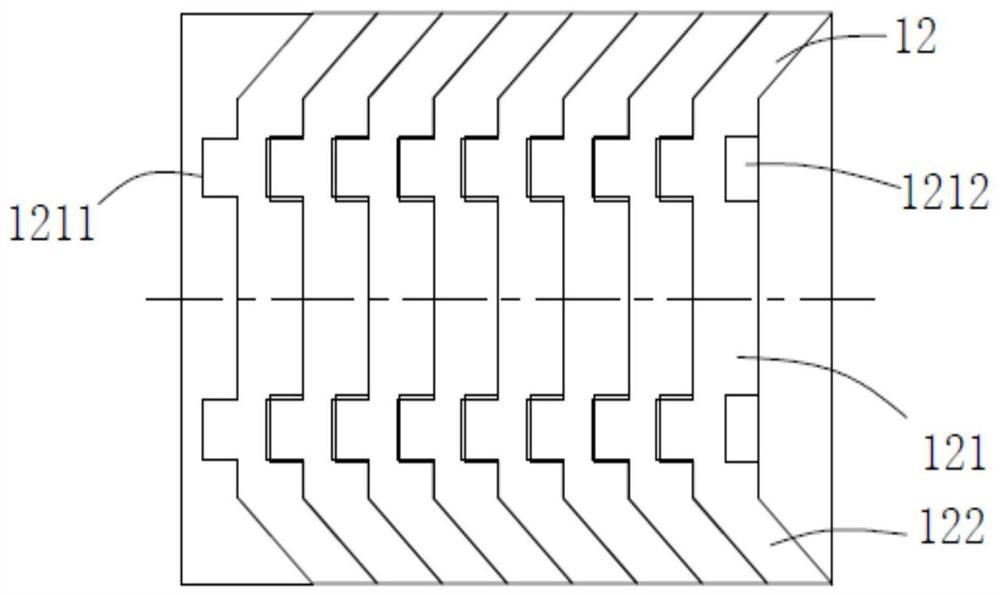

[0031] The plurality of rolling elements 12 are sequentially sleeved on the outer peripheral side of the rotating roller 11, and the rotating roller 11 drives the plurality of rolling elements 12 to rotate coaxially (eg, figure 1 Rotation axis b) in , the plurality of rolling elements 12 are connected in sequence to form a rolling surface.

[0032] It can be understood that each rolling piece 12 has a thickness, and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com